robot cnc milling machine The ROBODRILL Plus offers the versatility to handle a wide range of machining applications for large or small manufacturers. It’s ideal for high-volume manufacturing production environments . Using old panel as splice box. New meter base and new panel in new location, 8' away from original panel that was slightly behind a new furnace. The old panel has a nipple going up into the rafters in the basement.The key difference between a junction box and an outlet is their intended use. A junction box is designed to protect electrical connections, while an outlet is designed to provide a connection point for devices. While an outlet may have some internal wiring and connections, .

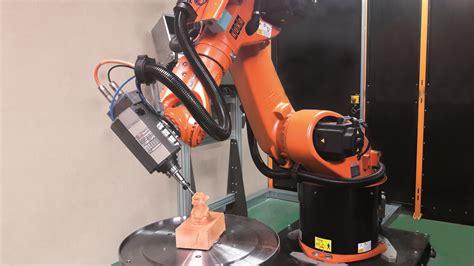

0 · robotic milling spindle

1 · robotic arm milling machine

2 · robotic arm cnc milling

3 · kuka milling robot price

4 · kuka cnc milling robot

5 · grinding robot versus cnc machine

6 · automated cnc holster milling machine

7 · alternatives to cnc machining

$12K+

The ROBODRILL Plus offers the versatility to handle a wide range of machining applications for large or small manufacturers. It’s ideal for high-volume manufacturing production environments .When choosing a CNC Milling robot, consider the types of parts you produce, your shop's needs, and available floor space. Articulated arm robots are very flexible but require more space, while gantry-style robots save space but are . Robot machine tending with a Fanuc robot at DMG MORI. Workholding by Schunk. I don’t think many really understand how much work has been outsourced in the last 20+ years. Good News: I am .

Autonomous mobile robots and mobile platforms for flexible automation: sensor technology, no-code programming, state-of-the-art battery technology, all payloads. KUKA milling robots .Discover FANUC ROBODRILL – the multipurpose 5-axis CNC milling, drilling and tapping centre that delivers unrivalled quality and precision at great hourly rates. The most significant advantage to manufacturers of milling robots is their lower cost compared to CNC machines. Depending on the application, robots can be roughly 30-70% of the cost of a CNC machine.Solutions for Robotic Machining and Machine Tending Robots. FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: Loading and unloading raw materials. Transferring .

CNC robots perform tasks like milling, drilling, turning, and cutting. But unlike a traditional CNC machine, robots can do these tasks with even more accuracy and consistency. They're also .This gives it an edge in accessing hard-to-reach areas and performing intricate milling tasks. Becoming the CNC machine. Once the milling end-effector(s) are in place and the CNC software is integrated, the robot pretty much becomes the CNC machine. It can carve, shape, drill, and perform all the tasks you'd expect from a traditional CNC machine.One complete horizontal 5-axis CNC milling machine, BLDC Servo Motor, C5 Ground ball screw 1204 and 1604, HIWIN dual linear rails, Harmonic Reducer the 5-axis (Metal Enclosure is Not included, can purchase separately)Lathe Tending 6 Axis Robot. Halter has advanced the field of CNC automation and developed a loading robotic arm, easily connected to any CNC machine. The TurnStacker Series are robotic loading solutions designed specifically for your .

While CNC machines can adequately perform specific tasks like milling, drilling, turning, etc., CNC robotics can do all these operations. These robots can also move along different complex paths. CNC machines often have three or four degrees of freedom which is usually enough for many machining operations.The HALTER LoadAssistant can be used by a CNC milling machine for loading of rectangle workpieces. Both small and medium series can efficiently be loaded by the robot arm into any existing or new CNC milling machine. You can get started right away and let your CNC milling machine perform more optimally!

Table 1 makes a detailed comparison between industrial robots and CNC machine tools. Compared with CNC machine tools, industrial robots have the advantages of better flexibility, lower cost, larger working space, etc. At the same time, robot technologies are becoming more and more mature, which has become another important means of machining .Press/Machine Tending; Arc Welding Robots (MIG, TIG) Material Removal & Polishing; Milling & Cutting; Palletizing & Packaging; Spot Welding; Laser / Plasma Cutting; . There are several differences between traditional CNC milling and robotic milling. While both perform milling, drilling, and cutting, robotic applications perform these tasks .Robots and cobots offer the greatest degree of flexibility in an automation system. You can have different pick-up and drop-off locations, and you can incorporate a part-flipping station to combine multiple operations. Both platforms interface directly through the Haas control, eliminating the need for a third-party integrator, which means the overall package is less complex, less .

Used CNC Milling Machine. Robot: Collaborative Robot Universal Robots UR10e. Specifications: Payload: 12.5 kg; Reach: 1,300 mm; Safety Features: Built in sensors, force limited joints; Benefit: The cobot UR10e can work safely with human operators without extensive safety fencing. From part handling to machine tending, robots can perform these . ProCobots ProFeeder collaborative robot unit running next to a Haas CNC mill.https://www.procobots.com#procobots #haas #automation #profeeder #cobot #cncmill.Robotic milling involves adding the flexibility to replace a traditional CNC machine. Robot milling can now replace a machine tool in certain applications, bringing a high level of flexibility to use different tools in the 3D space. First of all, Robots are capable of producing the highest quality complex and unusual geometries parts.

Contact us today for your CNC Machine Tending Robot needs! Improve the performance & efficiency of your CNC machine with Halter's CNC Machine Tending Robots! . the all-in-one Universal (for turning and milling), the TurnStacker and the MillStacker. Compact, Premium, and Big. Available with a 26lbs, 55lbs, 77lbs, or 154lbs robot arm.

The Haas Robot Package 1 is a fully integrated, plug-and-play, 7 kg capacity robot system for Haas machines. The system is controlled entirely from the Haas control. Includes: 6-axis robot, mounting stand, software interface for direct control through the Haas machine, electrical interface box, safety guarding, and all necessary solenoids .RATTMMOTOR 750W Servo Motor Kit, Servo Motor with Servo Motor Driver and Brake Encoder Cable, CNC Controller Kit for CNC Engraver Milling Machine/Robot (750W Without Brake) 2.55 $ 142. 55. . Genmitsu 3018-PROVer V2 CNC Milling Machine, Desktop CNC for Beginner with Limit Switches & Emergency-Stop, Upgraded Z Axis Aluminum Spoilboard .

Top Features Of The CNC Mill Automation System. We understand industrial CNC milling machines, so this is why our milling solution includes everything you need to get to automated production fast and easily. VersaCart 1300 - .

Discover versatile tabletop milling machines for precision crafting, metalworking, and prototyping with top brands like Carbide 3D and Sherline. . Sherline 2010A Series 8-Direction CNC Tabletop Milling Machine Package (mm) Sherline Machining Tools. . Contact North America. HALTER CNC Robotics LLC 21995 Fillmore Road Cascade, Iowa 52033 United States T: 800 314 8261 [email protected] VAT ID: US473961908The high precision Loading unloading robot under studied is one of the CNC Machines developed to support the Intra-ocular Eye-Lens manufacturing process. the Robot uses two DC Servo Motor as the actuators for the position control in cartesian coordinate. The desired specification of the Robot is of a very high accuracy which is reaching 10μm in high speed, such that it is .

cnc machining company nj

Robot for milling – parameters . Milling is quite a popular application for robots, so every manufacturer has the right machine for this task. You should look for robots with large working space and payload (bigger robots are more rigid). If you need high accuracy and quality you should choose robot with absolute accuracy option. This is an .This same system can be used, with small changes, as a CNC plasma cutting machine (2D or 3D) with an incredible big area of work. Enter today in the robotic world with the minimum investment. . You can perform 2D and 3D modeling on any manageable material with a robotic milling cell, allowing hot wire cutting to provide a perfect and fast .Robotics. Machine shops are in a constant race to increase productivity while decreasing costs. CNC machine tools coupled with robotics are making that possible, addressing the issues of increasing labor wage and benefit costs as well as the need to maintain production in the face of a shrinking manufacturing workforce.

Robot loading CNC milling machine at the Danish company IQ Metal. By using robot for automatic serving CNC machines, employees can perform other tasks while .Today, Robotor’s machines are the most advanced technological tools for the reproduction of all 3D designs with stone materials. The system requires only a few simple preliminary manual operations for it to then work autonomously. . A true revolution in programming for CNC milling robots. From complex programming by expert operators to self .Automated machine tending uses a CNC robotic arm to automate the loading and unloading of parts in a CNC machine. They can easily pick up raw materials, place them into the CNC machine, and activate a predetermined CNC program. Once the machining process is complete, they can remove the finished part and place it in a designated area. CNC Robotics is pioneering the use of industrial robots as an alternative to traditional machine tools, improving the productivity of manufacturing organizations cost-effectively. These machines are often used in the automotive and aerospace industries and other manufacturing and production settings.

Integrated: RO1 comes equipped with built-in relays to control almost any machine on the market, including plug-and-play support for Haas CNC milling machines. Speak to our solutions team today to organize a free, 30-day onsite trial and get expert advice on everything you need to deploy your first robot. Up to this point, milling has been accomplished with special milling and CNC machines. But milling robots offer advantages over these traditional milling methods. Flexibility — The typical 6 ‑axis articulated robot offers more movement flexibility than a normal milling machine. A robot can mill a .

robotic milling spindle

robotic arm milling machine

The political showmanship around metal detectors is happening as Democratic members express fear that their colleagues might put them in physical danger on multiple fronts.

robot cnc milling machine|alternatives to cnc machining