durable metal sheet standing seam roll forming machine Standing seam roll formers are the optimal equipment to produce interlocking metal panels for roofs, walls, and architectural façades. Their versatility, efficiency and automation capabilities make roll forming ideal for . Large, commercial-style 430 grade stainless steel baffle filter maximizes airflow and minimizes grease while the hood is in operation. The THOR Kitchen 36 .

0 · zimmerman standing seam roll former

1 · used standing seam panel machine

2 · standing seam roof panel machines

3 · standing seam roof machines used

4 · standing seam roll former machines

5 · roofing panel roll forming machine

6 · portable standing seam roofing machine

7 · portable standing seam roll former

control beyond the typical single duct box. They are specifically designed for precise air delivery throughout the entire operating range, regardless of the installed inlet conditions. They also offer improved space com-fort and flexibility for a wide variety of HVAC applications. SDR terminals take advantage of typical benefits pro-

Standing seam roll forming machines are specialized lines designed to continuously form interlocking standing seam metal roof panels from coils of sheet metal. Key features of standing seam roll formers: Produce . Standing seam roll formers are the optimal equipment to produce interlocking metal panels for roofs, walls, and architectural façades. Their versatility, efficiency and automation capabilities make roll forming ideal for .

The Schlebach Quadro PLUS is the most advanced, flexible, capable portable metal roofing panel machine. Contact us today to learn more! Standing seam rollforming system with 11 profiles; instant changeover

Snap lock standing seam roll forming machines are equipment used to produce standing seam metal roofing panels. They form the distinctive raised vertical seam along the panel edges which interlock to create a .Our US made roll forming machines provide precision jointed panels that can achieve all your portable needs. Whether you’re an existing professional roofer or someone looking to start their own roofing company, we have the machine for .

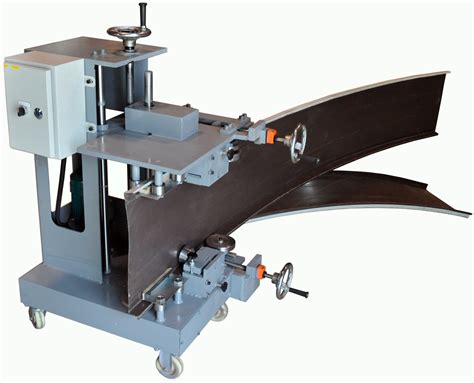

1.5″ & 2″ standing seam panel curver Schlebach Slasher 1250 With Coil Processing: slit-to-width and cut-to-length, the Slasher 1250 takes automated metal slasher machine technology to a higher level of speed, strength and .Portable Standing seam roof panel roll forming machine SS4E-15 for 1" or 1.5" double standing seam profiles. Indispensable in the production of metal roof and wall panels, including standing seam profiles.

zimmerman standing seam roll former

Key features include efficient production, durable construction, and an advanced roll forming system ensuring consistent quality. Additionally, JSEP provides robust customer support and customization options to meet specific project needs.

The VS-150 machine is equipped with hydraulic drive and front hydraulic scissors shear, 110 volt – 1 phase power, 40 FPM speed. It produces the 1″ and 1 1/2″ Standing Seam profile and “U-Panels in the base model machine, adjustable .Knudson light-gauge steel (LGS) framing component machines stand alone or as the centerpieces of integrated CAD-to-Component cold-formed steel (CFS) framing systems. Compliment any system with an accessory profile machine – .

Standing seam roll forming machines are specialized lines designed to continuously form interlocking standing seam metal roof panels from coils of sheet metal. Key features of standing seam roll formers: Produce popular architectural metal roofing; Gradually cold-form panels through progressive dies; Form seams allowing expansion/contraction

Standing seam roll formers are the optimal equipment to produce interlocking metal panels for roofs, walls, and architectural façades. Their versatility, efficiency and automation capabilities make roll forming ideal for both small and high volume production.

used standing seam panel machine

The Schlebach Quadro PLUS is the most advanced, flexible, capable portable metal roofing panel machine. Contact us today to learn more! Standing seam rollforming system with 11 profiles; instant changeover

Snap lock standing seam roll forming machines are equipment used to produce standing seam metal roofing panels. They form the distinctive raised vertical seam along the panel edges which interlock to create a weathertight roof surface.Our US made roll forming machines provide precision jointed panels that can achieve all your portable needs. Whether you’re an existing professional roofer or someone looking to start their own roofing company, we have the machine for you.

1.5″ & 2″ standing seam panel curver Schlebach Slasher 1250 With Coil Processing: slit-to-width and cut-to-length, the Slasher 1250 takes automated metal slasher machine technology to a higher level of speed, strength and stacking ease.Portable Standing seam roof panel roll forming machine SS4E-15 for 1" or 1.5" double standing seam profiles. Indispensable in the production of metal roof and wall panels, including standing seam profiles.

Key features include efficient production, durable construction, and an advanced roll forming system ensuring consistent quality. Additionally, JSEP provides robust customer support and customization options to meet specific project needs.The VS-150 machine is equipped with hydraulic drive and front hydraulic scissors shear, 110 volt – 1 phase power, 40 FPM speed. It produces the 1″ and 1 1/2″ Standing Seam profile and “U-Panels in the base model machine, adjustable width panels of 9″ to 24”.

Knudson light-gauge steel (LGS) framing component machines stand alone or as the centerpieces of integrated CAD-to-Component cold-formed steel (CFS) framing systems. Compliment any system with an accessory profile machine – from cold-rolled channel (CRC) to hat/furring channel. Standing seam roll forming machines are specialized lines designed to continuously form interlocking standing seam metal roof panels from coils of sheet metal. Key features of standing seam roll formers: Produce popular architectural metal roofing; Gradually cold-form panels through progressive dies; Form seams allowing expansion/contraction Standing seam roll formers are the optimal equipment to produce interlocking metal panels for roofs, walls, and architectural façades. Their versatility, efficiency and automation capabilities make roll forming ideal for both small and high volume production.The Schlebach Quadro PLUS is the most advanced, flexible, capable portable metal roofing panel machine. Contact us today to learn more! Standing seam rollforming system with 11 profiles; instant changeover

standing seam roof panel machines

Snap lock standing seam roll forming machines are equipment used to produce standing seam metal roofing panels. They form the distinctive raised vertical seam along the panel edges which interlock to create a weathertight roof surface.Our US made roll forming machines provide precision jointed panels that can achieve all your portable needs. Whether you’re an existing professional roofer or someone looking to start their own roofing company, we have the machine for you.

1.5″ & 2″ standing seam panel curver Schlebach Slasher 1250 With Coil Processing: slit-to-width and cut-to-length, the Slasher 1250 takes automated metal slasher machine technology to a higher level of speed, strength and stacking ease.Portable Standing seam roof panel roll forming machine SS4E-15 for 1" or 1.5" double standing seam profiles. Indispensable in the production of metal roof and wall panels, including standing seam profiles.Key features include efficient production, durable construction, and an advanced roll forming system ensuring consistent quality. Additionally, JSEP provides robust customer support and customization options to meet specific project needs.The VS-150 machine is equipped with hydraulic drive and front hydraulic scissors shear, 110 volt – 1 phase power, 40 FPM speed. It produces the 1″ and 1 1/2″ Standing Seam profile and “U-Panels in the base model machine, adjustable width panels of 9″ to 24”.

metal fabricators utah

metal fabricators pittsburgh pa

Get the best deals on Collectible Metal Lunchboxes (Pre-1970) when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

durable metal sheet standing seam roll forming machine|standing seam roof machines used