aluminium sheet metal manufacturing process To unlock the full potential of aluminum sheets, they have undergone complex and precise processes from bauxite to this remarkable metal. Understanding the manufacturing process allows us to appreciate the art and .

Find many great new & used options and get the best deals for 2001 KAWASAKI CONCOURS ZG1000 FUSE BOX JUNCTION BOX at the best online prices at eBay! Free shipping for many products!

0 · the process of making aluminium

1 · production of aluminium from bauxite

2 · how is aluminium currently produced

3 · how do we get aluminium

4 · how aluminium is produced

5 · aluminium smelting process flow chart

6 · aluminium manufacturing process flow chart

7 · aluminium extraction process flow chart

New Zinus Quick Lock® 4" Metal Smart Box Spring® Mattress Foundation, Queen: New Queen-Size-Box-Spring, 9 inch Box Spring Queen Box Spring Queen Only High Profile,Metal Mattress Foundation,Easy to Assemble,Heavy Duty,No Squeaky,with Box Spring Cover:

As one of the UK's leading suppliers of custom-cut metal, we're passionate about aluminium and its many uses. Below, we'll walk you through the entire process of how aluminium is made, step-by-step - from extracting the raw materials to turning it into the finished product. The manufacturing of aluminum sheets involves transforming aluminum and its alloys through stages of melting, casting, pre-rolling preparation, flat rolling, heat treatment, and finishing. This creates either single sheets or .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .

cnc machine operator training rhode island

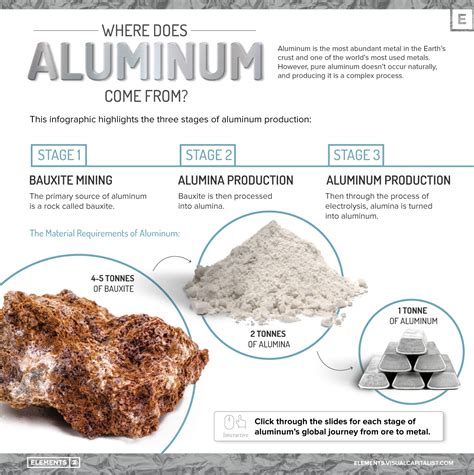

Discover the comprehensive process of aluminum sheet production, including raw materials, manufacturing techniques, and sustainability practices.Aluminum sheets are made through a complex manufacturing process that involves several stages. The process begins with the extraction of bauxite, a mineral that is the primary source of aluminum. Bauxite is refined to produce . To unlock the full potential of aluminum sheets, they have undergone complex and precise processes from bauxite to this remarkable metal. Understanding the manufacturing process allows us to appreciate the art and .The manufacturing process of aluminum sheet metal involves several steps, including casting, rolling, annealing, and finishing. Aluminum sheet metal is commonly used in aerospace, .

Aluminum sheet metal fabrication is the art of shaping and molding aluminum into functional products. This process involves cutting, bending, and assembling to meet precise .

the process of making aluminium

Beginning with bauxite extraction, we explore the transformation into alumina via the Bayer process, and subsequent conversion into aluminum through the Hall-Héroult . As one of the UK's leading suppliers of custom-cut metal, we're passionate about aluminium and its many uses. Below, we'll walk you through the entire process of how aluminium is made, step-by-step - from extracting the raw materials to turning it into the finished product.

The manufacturing of aluminum sheets involves transforming aluminum and its alloys through stages of melting, casting, pre-rolling preparation, flat rolling, heat treatment, and finishing. This creates either single sheets or rolled materials with a rectangular cross-section. Fabrication processes transform aluminum sheets into useful products. This guide will teach you how to cut, better ways of forming, and assembling aluminum sheets. Finally, you will learn the best finishing techniques, applications and cost saving ideas during fabrication process. Keep reading to be an expert in aluminum sheet metal fabrication.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

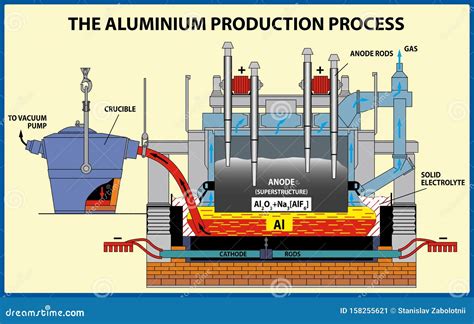

Discover the comprehensive process of aluminum sheet production, including raw materials, manufacturing techniques, and sustainability practices.Aluminum sheets are made through a complex manufacturing process that involves several stages. The process begins with the extraction of bauxite, a mineral that is the primary source of aluminum. Bauxite is refined to produce alumina, which is then smelted in a large-scale electrolytic cell to separate the aluminum from other impurities.

To unlock the full potential of aluminum sheets, they have undergone complex and precise processes from bauxite to this remarkable metal. Understanding the manufacturing process allows us to appreciate the art and science behind this essential material.

The manufacturing process of aluminum sheet metal involves several steps, including casting, rolling, annealing, and finishing. Aluminum sheet metal is commonly used in aerospace, automotive, construction, electronics, and packaging industries.Aluminum sheet metal fabrication is the art of shaping and molding aluminum into functional products. This process involves cutting, bending, and assembling to meet precise specifications. Its popularity stems from aluminum’s excellent properties, like lightness and strength. Beginning with bauxite extraction, we explore the transformation into alumina via the Bayer process, and subsequent conversion into aluminum through the Hall-Héroult process. We delve into the creation of aluminum alloys and their various applications, and the techniques employed in aluminum shaping.

As one of the UK's leading suppliers of custom-cut metal, we're passionate about aluminium and its many uses. Below, we'll walk you through the entire process of how aluminium is made, step-by-step - from extracting the raw materials to turning it into the finished product. The manufacturing of aluminum sheets involves transforming aluminum and its alloys through stages of melting, casting, pre-rolling preparation, flat rolling, heat treatment, and finishing. This creates either single sheets or rolled materials with a rectangular cross-section.

cnc machine operator training jackson tn

Fabrication processes transform aluminum sheets into useful products. This guide will teach you how to cut, better ways of forming, and assembling aluminum sheets. Finally, you will learn the best finishing techniques, applications and cost saving ideas during fabrication process. Keep reading to be an expert in aluminum sheet metal fabrication.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper. Discover the comprehensive process of aluminum sheet production, including raw materials, manufacturing techniques, and sustainability practices.Aluminum sheets are made through a complex manufacturing process that involves several stages. The process begins with the extraction of bauxite, a mineral that is the primary source of aluminum. Bauxite is refined to produce alumina, which is then smelted in a large-scale electrolytic cell to separate the aluminum from other impurities.

To unlock the full potential of aluminum sheets, they have undergone complex and precise processes from bauxite to this remarkable metal. Understanding the manufacturing process allows us to appreciate the art and science behind this essential material.The manufacturing process of aluminum sheet metal involves several steps, including casting, rolling, annealing, and finishing. Aluminum sheet metal is commonly used in aerospace, automotive, construction, electronics, and packaging industries.

production of aluminium from bauxite

how is aluminium currently produced

Aluminum sheet metal fabrication is the art of shaping and molding aluminum into functional products. This process involves cutting, bending, and assembling to meet precise specifications. Its popularity stems from aluminum’s excellent properties, like lightness and strength.

cnc machine operator programmer

how do we get aluminium

The Abrites Distribution Box is a proprietary set of cables and pins, allowing the AVDI to connect to different vehicles and modules, with CAN and K-Line protocols. It provides in-vehicle connection options, as well as bench and boot mode.

aluminium sheet metal manufacturing process|aluminium extraction process flow chart