sheet metal design practice pdf Sheet metal models can be designed in following methods: Design sheet metal from flatten state. Design sheet metal from solid. Design sheet metal from surface. Copy and Paste feature . Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting .

0 · solidworks sheet metal drawing pdf

1 · sheet metal practice drawings pdf

2 · sheet metal drawing pdf download

3 · sheet metal drawing exercises pdf

4 · sheet metal design handbook pdf

5 · sheet metal design guideline pdf

6 · sheet metal design calculations pdf

7 · sheet metal calculations pdf

Junction Box, IP67 Waterproof Plastic Enclosure for Electrical Project, Hinged Grey Cover, Includes Mounting Plate and Wall Bracket 290×190×140mm (11.4"×7.5"×5.5")

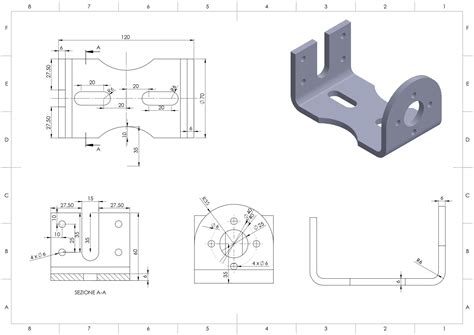

DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can .In this exercise, you’ll create a sheet metal bracket. You’ll use a combination of different flange features to create the base and utilize sheet metal features to finish the part.Sheet metal models can be designed in following methods: Design sheet metal from flatten state. Design sheet metal from solid. Design sheet metal from surface. Copy and Paste feature .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

This lesson focuses on designing a sheet metal part from the flattened state.to include a series of bends. The model and drawings will also serve as a classroom for examination questions .

SHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or .DESCRIPTION. Sheet Metal teaches you how to build sheet metal parts using SolidWorks mechanical design automation software. Building standalone sheet metal parts, and .This textbook is a great help for SOLIDWORKS users new to sheet metal design. It consists of total 132 pages covering the sheet metal design environment of SOLIDWORKS. It teaches .

Source: www.pinterest.ca I want to practice please. Sheet metal 2d drawings for practice pdf 2012 solidworks help dxf/dwg files (*.dxf *.dwg files) another area where we can practice our cad skills is to draw the neutral axis .

Short Desciption: This "Workshop Practice Series 08 Sheet Metal Work" book is available in PDF Formate. Downlod free this book, Learn from this free book and enhance your skills .CATIA Sheet Metal Design 3DEXPERIENCE® R2022x Sketch Based Profile Specifies the sketch to be used for the profile of the wall Angle Specifies the angle or rotation of the wall Specify Automatic and select the edge shown below. Multiple edges can be chosen, if desired. Set the Type to be Outer.The height will be measured from the bottom face of the wallUnderstanding the fundamentals of sheet metal fabrication ; The properties of sheet metal materials including aluminum, stainless steel, cold-rolled steel, and beryllium copper; The forming basics, cutting methods, and springback management of sheet metal ; Design guidelines for curls, hems, holes, slots and moreSheet Metal Certification Sample Exam Question 1: Design this part in SolidWorks using Sheet Metal features Unit system: MMGS (millimeter, gram, second) Decimal places: 2 Part Origin: Arbitrary Part Material: Aluminum, 1060 Alloy Material Density: 0.0027 g/mm^3 Sheet Metal Thickness: 1.20 mm Inner Bend Radius: 1.00 mm

The Workshop Practice series provides excellent, practical advice to the hobbyist. . 08-Sheet Metal Work.pdf download. 54.4M . 09-Soldering And Brazing.pdf download. 21.5M . 10-Saws And Sawing.pdf . 19-Spring Design Manufacture.pdf download. 20.3M .Starting a New Sheet metal File 1. To start a new sheet metal file, click Get Started Launch > New on the ribbon. 2. On the Create New File dialog, click the Sheet Metal.ipt icon, and then click Create. Setting the Parameters of the Sheet Metal part 1. To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the SheetThe best practice in bending is to design bends in the exact directions to avoid reorientation and use a consistent bend radius. . Top 10 Design Considerations for Sheet Metal Fabrication 8 H&S Manufacturing has specialized in providing manufacturing components and custom manufacturing solutions. We haveprinciples used to determine layouts for sheet metal fittings. Includes practice layout and fabrication tasks that allow trainees to develop and demonstrate their skills. Sheet Metal Duct Fabrication Standards (7.5 Hours) Trainee Instructor ISBN 978-0-13-609909-3 (Module ID 04204-08) Explains how to determine the

Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge . A .pdf drawing can be attached to the uploaded model if further specifications are required.

solidworks sheet metal drawing pdf

sheet metal practice drawings pdf

This lesson focuses on designing a sheet metal part from the flattened state. In this case, you create a sheet metal part and then insert bend lines on which to fold the part. Learning Intentions At the end of these exercises, you should be able to: Create a sheet metal part, using Base Flange, Extruded Cut, Sketched Bend and Edit

Because Sheet Metal parts are manufactured from a single sheet of metal the part must maintain a uniform wall thickness. Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends

Boljanovic, Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) . SERVOMECHANISMS, QUALITY CONTROL, PROCESSING, IRON, MACHINE SHOP PRACTICE, MATERIALS, SILICON CARBIDES, END MILLING, . PDF download. download 1 .

The Aerospace Sheet Metal Design functions are available when you are in the Part environment. Several functions are integrated from the Part Design workbench. This task shows how to enter the workbench. Choose the Mechanical Design -> Aerospace Sheet Metal Design item from the Start menu. The Aerospace Sheet Metal toolbar is displayed and .

Solidworks Sheetmetal Exercise 192 Base Flange/Tab and Edge FlangeOct 25, 2024 - Explore Mahtabalam Khan's board "SolidWorks Sheet metal" on Pinterest. See more ideas about solidworks, sheet metal, sheet. Pinterest. . SolidWorks Sheet Metal Steel Cabinet (Top-Down Assembly) Metal Tutorial. . 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the .Documenting a sheet metal part ; Converting solid parts; Sheet metal setup; Investigating a sheet metal part; Prerequisites: Access to the Creo Parametric 5.0 software. The practices and files included with this guide might not be compatible with prior versions. Practice files included with this guide are compatible with the commercial version .

1. The document provides instructions for creating sheet metal brackets and parts using Solidworks. 2. Exercise 1 involves using base flanges, cuts, and chamfers to create a sheet metal bracket based on given dimensions and design intent. 3. Exercise 2 uses flange features to create another part, demonstrating skills like base flanges, sheet metal parameters, edge flanges, .Creo parametric tutorials for design engineers pdf Download . Tips AutoCAD 3D exercises pdf for Mechanical Engineering Free Download Autocad mechanical practice drawings pdf free Download Fundamentals of Tally.ERP 9 . he is working in the sheet metal industry as a designer. Additionally, he has interested in Product Design, Animation, and .

The Automotive Sheet Metal Design using NX CAD course provides an outline of the current Body in White (BiW) component design factors and detailed explanations about their signi˜cance to part function, cost, and reliabili-ty. In this course, the modern design methodology is examined, covering Design for Manufacturing and Assem-Sheet Metal Design.pdf - Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. ASCENT - Center for Technical KnowledgeTM is a division of RAND Worldwide(tm) No part of this manual may be reproduced in any form by any photographic, electronic, mechanical or other means. ASCENT is focused on specializing in the creation of .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) . %20can.pdf Deep Drawing of drinks cans . Hydro-forming – cheap tooling, no net

Solidworks Sheetmetal Exercise 192 Base Flange/Tab and Edge FlangeSheet Metal Workshop_Lab Manual - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides information about a Manufacturing Practice laboratory course for mechanical engineering students. The course objectives include introducing concepts like product dismantling and assembly, pneumatic components, sheet metal tools and .SOLIDWORKS Sheet Metal Design 2021 textbook has been designed for instructor-led courses as well as self-paced learning. It is intended to help engineers and designers interested in learning SOLIDWORKS for creating real-world sheet metal components. This textbook is a great help for SOLIDWORKS users new to sheet metal design. It consists of total 132 pages covering the .

sheet metal drawing pdf download

sheet metal drawing exercises pdf

$8.88

sheet metal design practice pdf|sheet metal practice drawings pdf