bend tangent line sheet metal Draw a line inside the bend allowance area that is one bend radius away from the bend tangent line that is placed under the brake nose bar. Put the metal in the . $38.99

0 · straight line bends

1 · straight line bend chart

2 · sheet metal bending diagram

3 · sheet metal bend formula

4 · sheet metal bend chart

5 · sheet metal bend

6 · how to bend sheet metal

7 · 90 degree bend sheet metal

Delivering commercial quality products, administering product support, manufacturing at scale and delivering on time within narrow delivery windows all across the country firmly cements Weld House as a leader in large scale, contract furniture manufacturing.

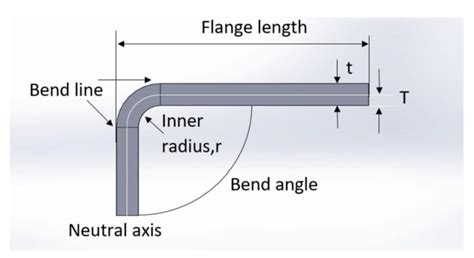

Bend tangent line (BL)—the location at which the metal starts to bend and the line at which the metal stops curving. All the space between the band tangent lines .Draw a line inside the bend allowance area that is one bend radius away from the bend tangent line that is placed under the brake nose bar. Put the metal in the . To help make sure you get your bends the correct sizes and in the right places we’ve created a Bending Calculator tool that calculates the complicated bend allowance and .The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line calculator.

You can successfully bend sheet metal without knowing why it works. Understanding the logic behind the process will enable you to design parts. Definition Of Terms • Mold point – the ideal .

n When sheet metal is bend, the inside surface of the bend is compressed and the outside surface of the bend is stretched. n Use 2 constant values. n Bend line: the layout line as a guide in .Open and closed bends present unique problems that require more calculations than 90° bends. In the following 45° and a 135° bend examples, the material is 0.050-inch thick and the bend .

The following illustrations shows the equation / calculation for determining the bend allowance when forming sheet metal. Each bent part has a base flange and then the bent area. The flange length is going to be what’s measured off the tangent of the base flange, to the end of the bent area on the part. How to apply our overall part size, bend .

straight line bends

Bend tangent line (BL)—the location at which the metal starts to bend and the line at which the metal stops curving. All the space between the band tangent lines is the bend allowance. Neutral axis—an imaginary line that has the same length after bending as it had before bending.Draw a line inside the bend allowance area that is one bend radius away from the bend tangent line that is placed under the brake nose bar. Put the metal in the brake under the clamp and adjust the position of the metal until the sight line is directly below the edge of the radius bar. More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of .

To help make sure you get your bends the correct sizes and in the right places we’ve created a Bending Calculator tool that calculates the complicated bend allowance and bend deduction values for you.

The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line calculator.

You can successfully bend sheet metal without knowing why it works. Understanding the logic behind the process will enable you to design parts. Definition Of Terms • Mold point – the ideal outside corner of the bend. • Bend radius (BR) – the actual radius of .n When sheet metal is bend, the inside surface of the bend is compressed and the outside surface of the bend is stretched. n Use 2 constant values. n Bend line: the layout line as a guide in bending. q Flat layout q Duplication of pattern q Projection through a set of points.Open and closed bends present unique problems that require more calculations than 90° bends. In the following 45° and a 135° bend examples, the material is 0.050-inch thick and the bend radius is 3⁄16-inch. Figure 1 shows an example for a 45° bend. Figure 1. Open bend. 1. Look up K-factor in K chart. K-factor for 45° is 0.41421-inch. 2.The following illustrations shows the equation / calculation for determining the bend allowance when forming sheet metal.

Each bent part has a base flange and then the bent area. The flange length is going to be what’s measured off the tangent of the base flange, to the end of the bent area on the part. How to apply our overall part size, bend length, and flange length dimensions when measuring your design.Bend tangent line (BL)—the location at which the metal starts to bend and the line at which the metal stops curving. All the space between the band tangent lines is the bend allowance. Neutral axis—an imaginary line that has the same length after bending as it had before bending.Draw a line inside the bend allowance area that is one bend radius away from the bend tangent line that is placed under the brake nose bar. Put the metal in the brake under the clamp and adjust the position of the metal until the sight line is directly below the edge of the radius bar. More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of .

To help make sure you get your bends the correct sizes and in the right places we’ve created a Bending Calculator tool that calculates the complicated bend allowance and bend deduction values for you.The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line calculator.You can successfully bend sheet metal without knowing why it works. Understanding the logic behind the process will enable you to design parts. Definition Of Terms • Mold point – the ideal outside corner of the bend. • Bend radius (BR) – the actual radius of .n When sheet metal is bend, the inside surface of the bend is compressed and the outside surface of the bend is stretched. n Use 2 constant values. n Bend line: the layout line as a guide in bending. q Flat layout q Duplication of pattern q Projection through a set of points.

Open and closed bends present unique problems that require more calculations than 90° bends. In the following 45° and a 135° bend examples, the material is 0.050-inch thick and the bend radius is 3⁄16-inch. Figure 1 shows an example for a 45° bend. Figure 1. Open bend. 1. Look up K-factor in K chart. K-factor for 45° is 0.41421-inch. 2.

The following illustrations shows the equation / calculation for determining the bend allowance when forming sheet metal.

cable junction box hensel

cable ring main junction box

13,440 Welding Fabrication jobs available on Indeed.com. Apply to Welder, Fabricator/welder, Millwright and more!

bend tangent line sheet metal|how to bend sheet metal