what can you do with sheet metal arc welding The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW. Gas Tungsten Arc Welding (GTAW or TIG) GMAW (MIG-MAG Welding) FCAW. Spot Welding. Seam welding. Resistance welding. MIG-MAG welding of thin sheets (22 .

The following things come in your iPhone 12 box. Obviously we're not counting the documentation and SIM removal tool here.

0 · when was stick welding invented

1 · what is stick welding called

2 · shielded metal arc welding videos

3 · shielded metal arc welding pdf

4 · shielded metal arc welding electrodes

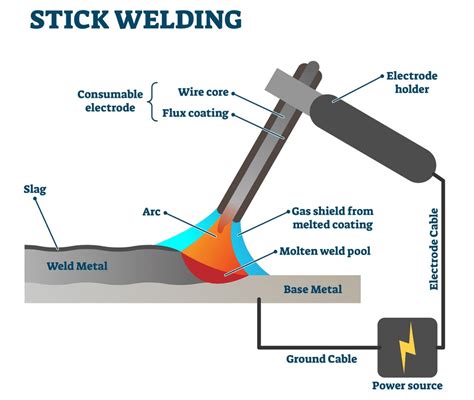

5 · shielded metal arc welding diagram

6 · mig welding sheet metal basics

7 · arc welding automotive sheet metal

As you can see there are plenty of great choices on the market if you’re looking for a portable electric lunch box. Some of them even come with handy carry bags and cutlery. Remember that you want to look for brands that you can charge in your vehicle or office, are . See more

when was stick welding invented

6 x 6 x 2 junction box

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It .

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW. Gas Tungsten Arc Welding (GTAW or TIG) GMAW (MIG-MAG Welding) FCAW. Spot Welding. Seam welding. Resistance welding. MIG-MAG welding of thin sheets (22 . Minimizing burn-through and distortion is essential to obtaining a good weld when gas metal arc welding thin-gauge materials. Gas metal arc welding (GMAW) is an effective method for joining light-gauge metals such as . Ensure snug fit-up for butt, lap, T, corner, and edge joints. An accurate fit-up contributes to both the aesthetic and structural integrity of the weld. Following these expert tips with precision and care, you can improve your . Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. In Sheet metal welding, the mating surfaces are subjected to .

thin sheet metal arc welding, thin plate welding with two different electrode sizeshow to weld thin metal correct??? this is the technique of welding thin m.

If significant loads will not be applied, yes you can tack weld expanded metal. However, you can not weld aluminium to steel. As others have said low heat and do a few test strips before attempting your final projects. . MORE: For those who like the things which YouTube doesnt, join us on a free mobile app called Telegram, under "Tractor Hoarders Group Chat", in case we get c. Imagine a welding process that minimizes distortion, enhances precision, and improves efficiency. Laser welding technology for sheet metal does exactly that, revolutionizing industries from automotive to high-tech electronics. This article explores the advantages of laser welding over traditional methods, detailing its superior heat control, speed, and flexibility. .

what is stick welding called

However, some practical advice might help you with higher gauge sheet metal. Stick Welding Equipment To Weld Thin Metal. Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology.The process for using MIG welding is relatively simple: the welder applies an electric arc between a consumable electrode wire and the thin sheet metal, creating a strong bond between the two pieces. Tungsten electrodes. Tungsten electrodes are often used with MIG welding for improved weld strength and esthetic appeal. They provide greater penetration into the metals being .Set the machine on the lowest settings and see if you can stike and maintain an arc. Do this on some scrap. Increase amperage in small steps until you can maintain a decent arc. Do a mock up of your fit and when you strike the arc strike it on the 3/16” angle and then drag the arc down to the sheet metal and then get off almost instantly. How to weld thin gauge steel similar to car body panel, down to .8mm or 1/32 of an inch thick with arc or stick welder.DisclaimerDue to factors beyond the c.

Flux core is one of the newer welding processes you can use to join thin sheet metal. It’s also one of the more complex and welding thin sheet metal with flux . When you weld with an electrode, you have a fairly predictable arc that you can focus on. Welding with a flux core shield is different, it is an arc that you don’t even see .

The program is offered 100% on campus at the Bridgeport, Connecticut and New London, Connecticut campuses. Students can earn a diploma in 10 months and will also be trained to perform Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Flux-Colored Arc Welding (FCAW). The thicker the base metal, the larger the welding rod diameter and the amperage. The larger the rod in relation to the thickness of the metal will cause a higher deposition rate and faster welding. If you select a welding rod with the same diameter as the metal thickness, this can cause too much heat and result in warping and blow-through.

A fun challenge to test the limits of stick welding thin metal while providing 4 practical tips. Stick welding is great because of the simple equipment, port. Various types of welding can be employed for car repair and customization, depending on the nature of the job and the desired results. Three popular types of welding used in this field are Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Plasma Arc Welding (PAW). Each type has its own advantages and is suitable for different . Enter the world of Flux Core Welding (FCW), a versatile technique with a unique approach to fusing materials.This method revolutionizes how welders approach sheet metal, from automotive repairs to constructing metal artworks.Grasping the principles of Flux Core Welding is essential for anyone interested in mastering this skill to achieve strong, durable, and reliable . To make the task easier, many welders use Metal Inert Gas (MIG) welding, which is known for its speed and precision.. However, setting up a MIG welder for sheet metal welding can be tricky, and choosing the right settings is .

There's often only one thing going wrong and this might be it.Shielded Metal Arc Welding (SMAW), also known as Manual Metal Arc (MMA) or Stick Welding can . Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide .

Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. . Gas tungsten arc welding (GTAW) You can also use the GTAW for high quality and low volume welding applications.For example, if you are welding a metal sheet and a rectangular rod, place the magnet against the rod. Make sure that when you do this, it is at the center. Then, you can weld the pieces together as you normally would. Avoid the magnetic piece as much as possible. Then, once most of it is completed, remove the magnet manually. Most guys can weld 1/16" with stick with practice and small rods. I know several really skilled guys who can weld a bit thinner than that, but it takes a lot of skill. Part of your issue might be that you will have to weld out of position ( vertical, possibly overhead). Most hobby welders don't do well in those positions and have a bit more .Switching polarity is an old sheet metal trick. It will make the rod hotter than the work...when the work is thin sheet, that is a very good thing. . This method seems to work the best for me. I just can't seem to get a good weld when I try having any arc gap at all. Comment. Post Cancel. Jim-Tx. Senior Member. Join Date: Oct 2006; Posts .

In this guide, we’ll deeply examine the spot welding procedure using a stick welder.Please keep reading-What Is Spot Welding? spot welding, is a resistance welding process. In this type of welding, two or more than two metal pieces or sheets are welded together by applying high pressure as well as heat to the welding area. This high pressure and heat come . How Do You Use a Stick Welder to Weld Thin Metal? The other name for the stick welding procedure is SMAW (Shielded Metal Arc Welding). This welding technique is older as compared to other types. However, it’s an easy procedure that guarantees you potent welds. Image Credit: vespaburoks, Pixabay Today, we're tackling the hot topic of using an arc welder for spot welding. If you're a welding enthusiast or a skilled professional looking to expand your repertoire, this is a post you simply can't afford to miss. . Stick welding, also known as shielded metal arc welding (SMAW), is a popular technique for fusing metals using an electric .Welding thick metal with high amps can also throw hot slag a fair distance. Get in habit of looking around between welds to see if you or something is burning. Your idea using metal covered wood bench will work if your careful. I have seen lots of old shops used for welding that are no better than your garage.

A3: Precautions to take while welding thin metal with a gasless MIG welder include using lower heat settings, employing proper welding techniques (e.g., tack welding), utilizing a heat sink to draw excess heat away from the weld area, and . Introduction to Gas Tungsten Metal Arc Welding (GTAW) Introduction to Gas Metal Arc Welding (GMAW) All of this training and knowledge prepares candidates to work on-site safely as they prepare for an exciting, fulfilling, and hands-on career in the manufacturing industry. Did you know? Goodwin University’s Welding certificate program is now .

Work offsets work like presets on your radio, except you store a location .

what can you do with sheet metal arc welding|shielded metal arc welding diagram