cnc machining titanium parts factories RAM Tool is a trusted CNC machine shop offering custom precision-machined titanium parts produced to meet your exact specifications. Get a quote today. If you're working with Wago 221 Series compact lever connector blocks or 2273 PushWire connectors, you'll want this multi-purpose electrical junction box. Known as the WAGOBOX XL, it's easy to fit and so easy to work with - a real time-saver when it comes to installation.•

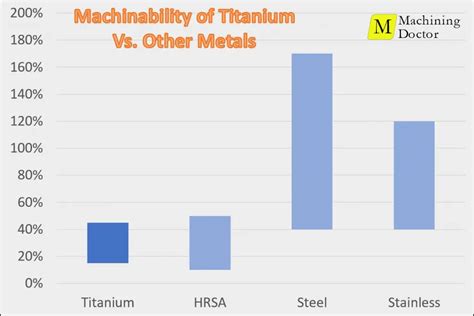

0 · titanium machinability chart

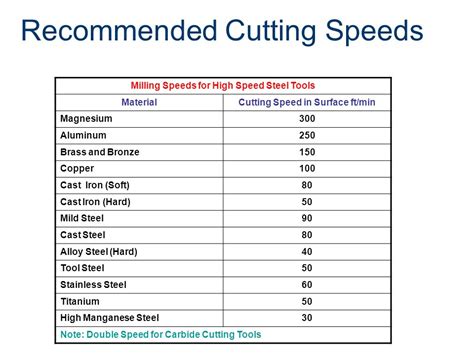

1 · recommended cutting speeds for titanium

2 · machining titanium without coolant

3 · is titanium hard to cut

4 · is titanium difficult to machine

5 · does titanium bend when machining

6 · best way to cut titanium

7 · best end mill for titanium

Place the junction box within 20 feet of the sensor, in an area that is protected from excessive fumes or moisture. Locate the cable entry on the bottom to minimize leakage problems.

RAM Tool is a trusted CNC machine shop offering custom precision-machined titanium parts produced to meet your exact specifications. Get a quote today.China leading provider of Metal CNC Machining Parts and CNC Machining Titanium Parts, Dongguan Zhaoyi Hardware Products Co., LTD. is CNC Machining Titanium Parts factory. Home; About Us . We are a supplier of CNC machining parts manufacturing for more than 10 years and help our customer put their products into the market. This durability suits CNC titanium machining for parts used in harsh environments. Corrosion Resistance: With its excellent resistance to corrosion, titanium is a prime choice for environments where rust and decay are concerns. . Best CNC Machined Parts Manufacturer and Factory in China. Offer Fast and Cost-Effective One-Stop CNC Machining .When CNC machining titanium, low cutting speeds are recommended. Tool tip temperatures can be easily increased by higher cutting speeds, which can compromise tools. Other related factors include sharp tools regularly replaced .

A practical example illustrates the importance of mastering Titanium CNC machining. An aerospace manufacturer faced significant challenges in producing turbine blades from titanium. They encountered high scrap rates and long lead times due to tool wear and inefficient machining processes. Mastering Titanium CNC Machining for Critical Parts 3 CNC, or Computer Numerical Control, is a manufacturing process that uses computerized controls to direct machine tools and produce highly precise parts. In this article, we'll explore the benefits of using aerospace CNC machining for .

eMachineShop has machined titanium parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed.Sourcing Guide for Cnc Machining Titanium Parts: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: cnc machining, machining parts, auto parts.

Choose the most reputable CNC titanium parts and turned parts manufacturers in the Dubai. CNC titanium parts exhibit excellent heat tolerance capacity and can withstand wide range of high temperature applications. The machined parts are strongly resistant to various chemicals. The machined parts are lightweighted and exhibits high strength.DEZE offers comprehensive titanium machining services, utilizing advanced techniques such as CNC turning, milling, drilling, grinding, water jet cutting, laser cutting, plasma cutting, and EDM. DEZE is a leading and dedicated manufacturer of high-precision Ti parts, capable of processing various grades of Ti, including Grade 1, Grade 2, and . CNC machining titanium parts are extraordinarily durable but can be difficult due to their excessive tensile strength. . Environmental sustainability is an increasingly vital aspect of contemporary manufacturing. The future of CNC machining titanium will entail focusing on sustainable practices, encompassing material waste reduction and .

Titanium CNC machining is a precise manufacturing process that involves the use of computer-controlled machines to remove material from a titanium workpiece, resulting in highly accurate and intricate titanium components. . The cost of CNC-machined titanium parts can vary heavily depending on several factors such as the complexity of the .Custom CNC Machining Titanium Parts. Many factories will stop quoting when they see titanium alloy products. Because titanium is hard, it leads to low production efficiency and tool wear. However, AIXI has rich experience in titanium alloy products. We know how to control the milling speed of the tool to reduce tool wear and maximize tool life. From the specialized tools, expertise and quality control measures required to CNC machine titanium, discover why titanium is a unique yet costly ma. Cookies +86 15099911516 [email protected] 14 years one-stop China custom CNC machining parts factory. Free project review. Home. Services. CNC Machining . CNC Turning. 5 Axis CNC Machining .

Our Titanium CNC machining services utilize state-of-the-art technology and machinery to provide high-quality precision machining of titanium parts. Our team of skilled professionals has extensive experience in working with titanium. We are equipped to handle a wide range of titanium machining projects, from simple to complex, with a focus on delivering consistent, accurate, .Titanium Grade 7 and Grade 23: With enhanced corrosion resistance and purity, they cater to niche needs, whether resisting acids or constructing medical implants. Challenges of CNC Machining Titanium. Every metal has its quirks, .

Design Consultation: Collaborate closely with our experts to optimize the design of your titanium parts, ensuring peak functionality and efficiency. Material Selection: Receive expert guidance in selecting the ideal titanium alloy, .

Titanium is an exceptional material for CNC machining, known for its ability to withstand high temperatures and resist chemical corrosion. Additionally, its lightweight nature and various other qualities make it highly . Explore advanced techniques in titanium CNC machining with Frigate to produce strong, lightweight parts that withstand extreme conditions. Launching FabX by Frigate Get An Instant Quote CNC milling is one of the most common manufacturing processes to produce precise and complex titanium parts. In this article, we will explore the whole process of CNC milling of titanium, including the preparation, machining, and finishing stages, as well as the challenges and best practices involved in working with this unique material.

titanium machinability chart

As one of the leading CNC machine spare parts machining titanium parts manufacturers and suppliers in China, we warmly welcome you to wholesale CNC machine spare parts machining titanium parts made in China here from our factory. All customized products are with high quality and competitive price.

The precision CNC machining parts industry in usa has seen over 100 years of development. At the heart of USA CNC machining lies a tapestry of technological advancements and unparalleled expertise. The United States boasts a cutting-edge technological landscape, and this reflects in its CNC machining capabilities. Introduction to CNC Machining Processes. CNC machining is a critical process in modern manufacturing that allows for the precise shaping of materials like aluminum, plastic, and titanium.These materials are widely used across industries due to their unique properties, including strength, durability, and flexibility. Designing Parts for CNC Titanium Machining . Given that titanium is costlier than other metals, it’s crucial to design your parts meticulously. This involves using CAD/CAM software for part design and manufacturing, creating well-designed fixtures and jigs to support machining, and considering design for manufacturability (DFM) for efficient .

During machining, heat builds up at the cutting edge, leading to thermal distortion of the workpiece and premature tool failure. Managing this heat is critical for achieving high-quality machined parts. CNC Machining Process for Titanium . The CNC machining process for titanium requires specialized knowledge and equipment to achieve high .

This metal also has excellent ductility and good machinability. Other reasons to choose titanium for CNC machining parts include: Durability: Titanium is highly durable and ideal for manufacturing CNC machined parts subjected to harsh or extreme working conditions. Non-magnetic: This metal has no magnetic characteristics. These unique properties create demand for precisely machined titanium parts, particularly in sectors where durability, weight savings, and longevity are crucial. CNC Machining and Its Role in Titanium Parts Production. CNC machining is a computer-controlled process used to precisely manufacture parts from raw materials, including metals like .Titanium Milling _____ Our state-of-the-art CNC machining centres, boasting 24/7 automation and rapid tooling setups, guarantee smooth, high-volume production of your titanium components. Need intricate details or challenging geometries? Our 5-axis milling tackles complex titanium parts with exceptional precision.

recommended cutting speeds for titanium

Get the best deals for Voltron Dvd Collection at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

cnc machining titanium parts factories|best end mill for titanium