k-factor sheet metal Effortlessly calculate K-Factor for sheet metal bending with our free online calculator. Save time and improve accuracy. Try it now! $4.36

0 · sheet metal k factor definition

1 · sheet metal bending radius chart

2 · k factor sheet metal calculator

3 · k factor for stainless steel

4 · how to calculate k factor

5 · bending calculation for sheet metal

6 · bending allowance in sheet metal

7 · bend allowance k factor chart

$15.00

sheet metal k factor definition

Learn what K-Factor is and how to calculate it for sheet metal bending. Find out how to use it to design flat patterns, bend allowances and deductions for different angles and radii. See moreSince the K-Factor is based on the property of the metal and its thickness there is no simple way to calculate it ahead of the first . See moreA K-Factor will typically range between 0 and .5 for standard materials and thicknesses though smaller and larger K-Factors are possible. To help you begin I’ve included a K-Factor Chart below which contains common K-Factor starting points, good for general . See more

The K-Factor for a 180° bend is going to be meaningless because it’s tied to the Outside Setback which approaches infinity as the bend . See more Effortlessly calculate K-Factor for sheet metal bending with our free online calculator. Save time and improve accuracy. Try it now!

magnus steel box

The k-factor allows you to calculate the bend allowance, the outside setback, the bend deduction, and the flat layout of the precision part you’re forming. Defining the Neutral .Use our K-factor calculator to determine the position of the neutral axis in the sheet of metal you are planning to bend.

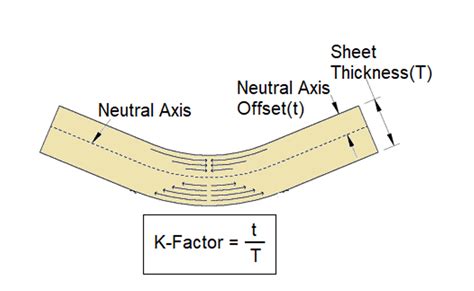

Learn how to calculate sheet metal flat length, bend allowance and bend deduction using K-factor or Y-factor. Find out the definition, formula and examples of K-factor and Y . The K-factor in Welding. In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend compresses while the outer portion expands (see .K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the .

What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses. In essence, it’s nothing more than the ratio of the sheet metal .The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and usually represented as a decimal value. The K . The k-factor, expressed as t/Mt, is a ratio that describes the neutral axis’s shift inward during bending. Note the last variable—the outside bend angle, as measured from the outside of the bend (see Figure 2).K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the .

How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°.

The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is . To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default for many CAD systems. To dial in your bend calculations, you first need to determine whether you go with the default k-factor value of 0.4468, calculate a custom k-factor, or reverse-engineer it based on some test bends. K-Factor– A constant determined by dividing the thickness of the sheet by the location of the neutral axis, which is the part of sheet metal that does not change length. So if the thickness of the sheet was a distance of T = 1 mm and the location of the neutral axis was a distance of t = 0.5 mm measured from the inside bend, then you would .K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.

Here I show the principle of the k factor in sheet metal design. This is one of the lessons of my Course about Solidworks Solid, Sheet metal and Weldments mo.K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.CATIA V5 is the metal bending software of choice across many industries. This tutorial covers how the K-Factor impacts metal bending and Learn how to calculate the K-factor in Sheet Metal Bending with this CATIA V5 tutorial.

Bending A chimney starter, a sample product of bending. Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. [1] Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses.Typical products that are made like this are .The K Factor in sheet metal bending is a crucial parameter that helps in determining the correct bend allowance and bend deductions for creating accurate sheet metal parts. It is essential for ensuring that the final dimensions of the bent parts match the design specifications.

sheet metal bending radius chart

k factor sheet metal calculator

K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.

Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal parts that were bent using the following formula:K-Factor, Bend Calculation, Bend Allowance, and Bend Deduction are all types of bend allowances that influence the length of a sheet metal flat pattern.SOLID. In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples. SOLIDWORKS. 3D CAD . Many designers reference a chart .Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. Y factor and K factor are defined by the location of the sheet metal .

The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part . Ever wonder what "K-Factor" means when defining your Sheet Metal Rules in Fusion 360? This Quick Tip provides more insight on how the K-Factor is used to det.

What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property. Unfolded flat size: The total length of the sheet metal when flattened; K-factor: The location of the neutral axis relative to the inside of the bend; Y-factor: The distance from the inside of the bend to the neutral axis; Bend allowance: The length of .

programs to produce accurate sheet-metal work. Many CAD programs, however, also work out bend allowances automatically by using K-factor calculations. (Or Y-factor in the case of Pro-E where Y-factor = K-factor * / 2). Bend allowances are calculated using a K-factor as follows: BA= (R + KT) A/180 where: BA = bend allowance R = inside bend radius The k-factor describes the neutral axis’s inward shift during bending. Press brake operators can calculate it precisely, especially after some test bends, but know that the k-factor is just one among many. . When sheet metal bends, it expands on the outside surface of the bend and compresses on the inside surface.

As mentioned earlier also, you can also make use of the Sheet Metal K Factor Chart for directly finding the K-Factor value if you don’t find it comfortable for you to calculate it by yourself. K-Factor Chart. Generally, a normal range of 0 to.5 is seen in the case of standard material and thicknesses. Having said that, larger and smaller K . To establish an accurate sheet metal model using the K-factor method, it’s crucial to find the appropriate source of K-factor that meets your engineering requirements. This will ensure that the physical part results are as accurate as desired. In some situations, it may not be possible to obtain accurate results by using a single K-factor .

The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and usually represented as a decimal value. The K-factor value depends on various factors, including the material properties, sheet thickness, bending radius, etc. . Accurately bending sheet metal into desired shapes directly influences the functionality and assembly of the final products. A critical concept here is the "K-Factor," vital in bending and bridging design with manufacturing, especially when using tools like SolidWorks. This post explains the importance of the K-Factor, its calculation, and its . K-factor and Y-factor in sheet metal both look at how bending affects the material and how much bending the metal will allow. When sheets of metal bend, the top surface compresses and the bottom expands. The boundary inside the metal between these two is the neutral radius. In flat metal, this boundary evenly bisects the material’s thickness .

mailbox mounting bracket lowes

Find great deals on eBay for Stamp Boxes Antique. Shop with confidence.

k-factor sheet metal|bend allowance k factor chart