cnc machine pdf notes Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. . In this guide, we will explore the advantages of metal siding, the different types available, the installation process, maintenance requirements, and the cost so you’ll be thoroughly informed about your choices when deciding if metal siding is right for your project.

0 · types of cnc machines PDF

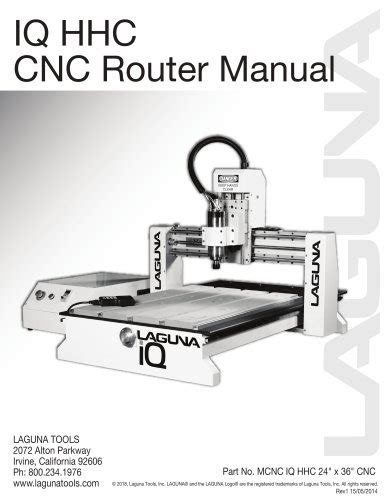

1 · cnc machine tool design PDF

2 · cnc machine manual PDF

3 · cnc machine drawing PDF

4 · cnc machine codes list PDF

5 · cnc machine books free download PDF

6 · cnc machine basic knowledge PDF

7 · cnc machine PDF download

To figure out which metal roof is right for you, it’s important to weigh the pros and cons of each type. 1. Aluminum is one of the best metal roofing types, thanks in part to its longevity and strong wind and fire resistance.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC .

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. .

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .CNC Overview By integrating a computer processor, computer numerical control (CNC) is obtained or “CNC” allows part machining programs to be edited and stored in the computer .CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .

How CNC Work? Each CNC machine has a CNC controller which can be programmed to drive the machine through a series of motions Axis: Each direction of motion of a CNC machine is .

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive RapidWhat is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeCNC Overview By integrating a computer processor, computer numerical control (CNC) is obtained or “CNC” allows part machining programs to be edited and stored in the computer memory permit diagnostics and quality control functions during actual machining. All CNC machining begins with a part program,

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

types of cnc machines PDF

cnc machine tool design PDF

How CNC Work? Each CNC machine has a CNC controller which can be programmed to drive the machine through a series of motions Axis: Each direction of motion of a CNC machine is called an axis. It is simply a direction of motion under the influence of the CNC controller. It can either be linear or rotary.

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,

CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

CNC Overview By integrating a computer processor, computer numerical control (CNC) is obtained or “CNC” allows part machining programs to be edited and stored in the computer memory permit diagnostics and quality control functions during actual machining. All CNC machining begins with a part program,CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

cnc machine manual PDF

cnc machine drawing PDF

There are several types of metal roofs available today, each with its own set of advantages. The most common materials used for metal roofs include steel, aluminum, .

cnc machine pdf notes|cnc machine basic knowledge PDF