sheet metal mechanical properties Have you ever wondered about the mechanical properties of different . CNC measuring machines in the HELICHECK series for contactless complete measurement of tools and production parts. Walter Maschinenbau GmbH is part of the UNITED GRINDING Group. Together with our sister company, Ewag AG, we consider ourselves to be a supplier of systems and solutions for the complete machining of

0 · sheet metal thickness range

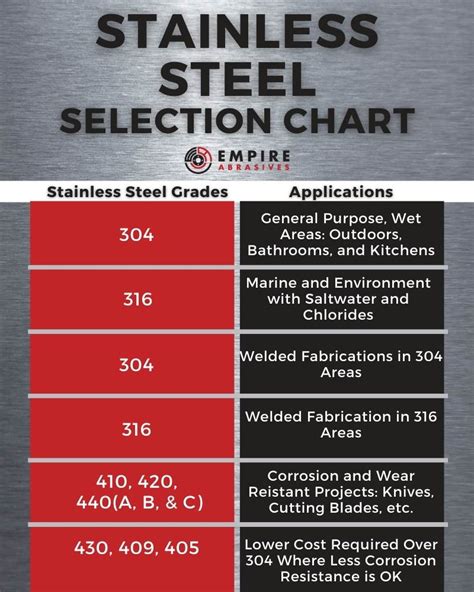

1 · sheet metal material selection chart

2 · sheet metal grades and properties

3 · most common sheet metal material

4 · metal sheet thickness in mm

5 · mechanical properties of sheet metal

6 · maximum thickness of sheet metal

7 · characteristics of sheet metal

Designed by Hoffman Fabrics, Holiday Wishes - Damask Hunter/Gold Metallic Fabric is a Hoffman Holidays Classic Christmas Fabric which is great for quilting, apparel and home decor.

Learn about the mechanical properties of sheet metal, including its strength, elasticity, ductility, and toughness. Get expert insights at MachineMfg.Have you ever wondered about the mechanical properties of different .Sheet metal is characterized by its light weight, high strength, conductivity . Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference.

sheet metal thickness range

sheet metal material selection chart

Medium Carbon Steels General mechanical engineering (tools, bearings, gears, shafts, bearings) Low Carbon Steels Steel structures (“mild steel”) – bridges, oil rigs, ships; reinforcement for .It must be realised that many material properties (such as toughness) vary between wide limits depending on composition and previous treatment. Any final design should be based on .The tables below provide properties of common engineering materials. The material property data provided are intended to be representative of the material described. The provided values tend .

Sheet metal is characterized by its light weight, high strength, conductivity (which makes it suitable for electromagnetic shielding), low cost, and good production efficiency. It has found widespread use in various industries, .

Grade Data Sheet Galvanized Steel - hot-dip zinc coated structural steel with guaranteed minimum yield strength. Meets ASTM A653-09 specifications/requirements.EDDS – COLD ROLLED – EXTRA DEEP DRAWING STEEL (EDDS) – This material is intended for fabricating identified parts where extremely severe drawing or forming in excess of the . Metal sheets have the same mechanical properties as the base metal. Thus, steel sheets have high tensile strength and durability suitable for use in constructions and machinery. At the same time, copper sheets often find .

junction box light fixture wiring diagram

sheet metal grades and properties

junction box leach field leaking

The characterization of high temperature performance of sheet metals such as titanium alloys is an essential prerequisite for the precise hot plastic forming and accurate structural behavior prediction of an engineering sheet part [1].For instance, when the Mach number increases, the surface temperature of a hypersonic vehicle will increase sharply with . Peer review under responsibility of the organizing committee of the Advances in Materials & Processing Technologies Conference doi: 10.1016/j.proeng.2017.04.108 ScienceDirect Advances in Material & Processing Technologies Conference Mechanical Properties Identification of Sheet Metals by 2D-Digital Image Correlation Method Van-Thuong .Metals Applications Ferrous metals Cast Irons Automotive parts, engine blocks, machine tool structural parts, lathe beds High Carbon Steels Cutting tools, springs, bearings, cranks, shafts, railway track Medium Carbon Steels General mechanical engineering (tools, bearings, gears, shafts, bearings) Click Metal for your Sheet Metal Needs. For your comprehensive sheet metal needs, why not check out Clickmetal? Not only do we stock a huge range of quality sheet metal products, but we can cater to all of your metal requirements ranging from bars to plates to mouldings. Give a member of our friendly team a call on 01794526090, or browse and .

Sheet metal materials exhibit unique physical and mechanical properties that make them suitable for various applications. The properties of sheet metal are influenced by factors such as the base metal composition, manufacturing process, and post-processing treatments.

Mechanical testing of metals—Modified Erichson cupping test sheet and strip: Part 1 Thickness up to 2 mm (first revision) . Where V is thickness of steel sheet, in mm. * Properties on mutual agreement between the purchaser and the manufacturer. 8 BEND .Mechanical properties (JIS ) Note a):・Chromate-freeeetreatment includes the chromate-freeeetreatment and the chromate-free phosphating treatment specified in JIS G 3323:2012. Note b):・Thehsymbol for chromate-free treatment shall be agreed upon between the partiesiinvolvededin delivery.rAsAsthe symbol,oleither the chromate-free 12 Mechanical Properties of Sheet Metal: Essential for Engineers and Fabricators Have you ever wondered what makes sheet metal so versatile in engineering? This article explores the fascinating world of sheet metal, diving into its material properties, manufacturing processes, and design.

This work presents a numerical study on the influence of variability in the mechanical properties of metal sheets in predicting the occurrence of springback and maximum thinning, for a sheet metal forming process. For this purpose, a mild steel was selected as reference material and the U-channel forming process was considered. The factors selected . In sheet metal forming operations, mechanical properties of the sheet material such as flow stress or stress-strain curves greatly influence metal flow and product quality 52. The flow stress can be determined by tensile tests which provide .Sheet metal is metal formed into thin, flat pieces, . In sheet hydroforming, variation in incoming sheet coil properties is a common problem for forming process, especially with materials for automotive applications. . rather than by the movable part of a die in a mechanical or hydraulic press. Unlike deep drawing, hydroforming usually does .

most common sheet metal material

Explore the physical, chemical, and mechanical properties of stainless steel. Gain a comprehensive understanding of stainless steel properties and identify the best grade for your particular application. . How does sheet metal evolve from raw material to intricate components in our everyday devices? This article dives into the fascinating .

The mechanical property ranges for Commercial, Forming, Drawing and High Temperature Steels are not mandatory. Table 4a. A792 Specifications for Typical (Non GALVALUME Coated Sheet Steel Mechanical Properties Ranges of Mechanical PropertiesA-mandatory) Table 4b. A 792 Mechanical Property Requirements, Structural Steel Base Metal (Longitudinal)

Online Acquisition of Mechanical Material Properties of Sheet Metal for the Prediction of Product Quality by Eddy Current; Co-Authored mostly with: P. Hora J. Heingärtner J. Heingartner; More from "Pavel Hora" (1) 2010-08 : Online Acquisition of Mechanical Material Properties of Sheet Metal for the Prediction of Product Quality by Eddy Current

INDUSTRY PROPERTIES FOR STEEL SHEETS – COLD ROLLED & HOT DIPPED ZINC COATED Typical Ranges For Mechanical Properties – Yield And Elongation Are Nonmandatory Cold Rolled C% Mn% P% S% Al% Hardness¹ Yield ksi Elong% r-value n-value CS Type A 0.10 max 0.60 max 0.030 max 0.035 max * B65 max 20-40 30 min – –The mechanical properties offered by cor ten steel sheet. . Corten sheet metal mechanical properties. Min. Yield Point Tensile Strength Elongation; IRSM 41- 97 [340 MPa] [480 MPa] 21% min: ASTM 588 GR. A [345 MPa] [485 MPa] 21% . Comprehensive anisotropic plasticity model for sheet metals with heterogeneous properties. . Aside from the microstructural mechanisms regulating the change of mechanical properties due to annealing, a comprehensive mesoscale framework to describe the plastic properties’ evolution for potential use in forming applications has not been .

The application of embossed structures close to the sheet surface allows for work hardening to be introduced into sheet metal materials, leading to an improvement in their mechanical properties. So far, this was demonstrated in previous research work via tensile tests with differently embossed dual-phase steel specimens.Ultrasonic energy is used for applying severe plastic deformation on metal surfaces. In the present work, the effect of ultrasonic vibration on the formability, microhardness and microstructural properties of St14 steel sheet has been investigated. To be precise, a semi-hemispherical-head forming tool had shaped the specimens until the necking started to happen. Conventional as .

One of nickel sheet metal’s most important mechanical properties is its ductility. Ductility measures a material’s ability to deform under tensile stress. Nickel sheet metal is highly ductile and can easily form into various shapes without breaking. Strength. Another important mechanical property of nickel sheet metal is its strength.

junction box installation cost

Various sheet metal material grades are available in the market. Product functional requirements and material physical and mechanical properties have an impact on the Material selection. Type of rolling operation (hot rolling or cold rolling operation) also impacts sheet metal material properties. Following are some of the commonly used sheet .Study with Quizlet and memorize flashcards containing terms like The point at which steel begins to develop brittle properties is when the carbon content is just above ______., The letter prefix for the AISI classification system for carbon steels indicates the ______., The principal difference between plain carbon steel and HSLA steel is ______. and more.

[12] Marciniak Z, Kuczynski K. Limit strains in the processes of stretch-forming sheet metal. 1967, Int. J. of Mechanical Sciences 9 (9), 613-620. [13] ISO 16842, 2021 – Metallic materials — Sheet and strip — Biaxial tensile testing method using a cruciform test piece.

Due to the low formability at room temperature, the application of 7XXX aluminum alloy sheet is limited. The hot forming-quenching process is an effective technology for the forming of some complex-shaped aluminum alloy parts. In this study, heat treatment was integrated with sheet metal stamping to improve formability and strength of 7075 aluminum alloy sheet. The . Table 2 shows the base metals used in tailored sheet specimens and the mechanical properties obtained from uniaxial tensile tests. Also, Table 3 shows the mechanical properties of tailored sheet specimens obtained from the usual uniaxial tensile tests. The work-hardening exponents of laser-welded sheet specimens are lower than the mean value of those . Cite this article as: Harald Schmid, Marion Merklein, Study of the mechanical properties of sheet metals drawn through drawbeads, Manufacturing Rev. 6, 14 (2019) All Figures. Fig. 1. Strip drawing test with geometry and drawbead height h 1 and h 2 according to in process illustration (a) and used test bed with clamping and drawing unit (b).

The microstructure and mechanical properties of the welded sheet formed by the die were examined. . Determined mechanical properties of tailor welded sheet metal blanks and also studies done on .

We can use water glass investment casting technology to cast and machining railway parts according to customer requirements and standards. We have a variety of high-precision machining equipments and comprehensive inspection equipments. We can provide assembly and surface treatment services.

sheet metal mechanical properties|most common sheet metal material