how metal sheets are made Sheet Metal fabrication is a manufacturing process where flat sheets of steel or aluminum are turned into into metal structures or products, by cutting, punching, folding, and assembling.. Brick House With Red Metal Roof. Red works well with other warm and earthy tones. The red in a brick house complements a red metal roof. Country Red R Panel. White House With Red Metal Roof. White is the perfect blank canvas that blends well with any roof color.

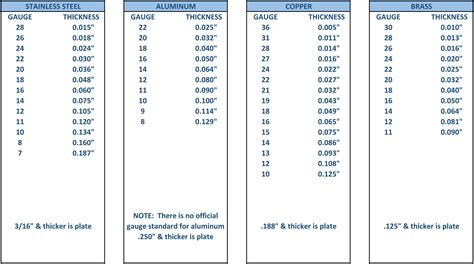

0 · which thickness called sheet metal

1 · sheet metal specifications

2 · sheet metal process in impl

3 · sheet metal examples

4 · maximum thickness of sheet metal

5 · material used in sheet metal

6 · different types of sheet metals

7 · characteristics of sheet metal

Official 2023 White House Christmas Ornament and Official 2022 White House Christmas Ornament, Bundle

There are four basic stages in the process of making sheet metal: melting, pouring, pickling and lastly, rolling and annealing. Sheet metal is made for a wide range of purposes, from automotive parts to rain gutters to medical equipment and building components.

In this factory video tour, we will show you a metal roofing sheet making process for your ease. So, watch this video till the end. Learn about the detailed process of manufacturing galvanized steel sheets. From raw material to final product, understand how these sheets are produced. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and annealing the metal into a sheet. 1. Melting. The first step, unsurprisingly, is to melt the .

Sheet Metal fabrication is a manufacturing process where flat sheets of steel or aluminum are turned into into metal structures or products, by cutting, punching, folding, and assembling..The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Sheet metal is a metal that is shaped into thin, flat pieces by hot and cold rolling industrial process. Sheet metal is one of the basic forms of metalworking and can be cut and bent into various shapes. How is sheet metal made? Sheet metal is made by running hot slabs of metal through a series of roughing rolling stands that makes them thinner .

Sturdy and Reliable: these metal sheets are made of quality 304 stainless steel (not magnetic), sturdy and rust resistant, with flat edge and coated surface, which are reliable to use and can provide a long term service for you; After tearing the film, the plate itself has a certain . Have you ever wondered how they make the metal panels for roofing or siding installation? Making steel roofing Metal setup. Wagler Metal Sales Roofing and Si. Another variable of sheet metal is the material it can be made from, including aluminum, bronze, copper, brass, and a variety of types of steel. Steel sheet metal manufacturing process Because sheet metal is a relatively basic and straightforward product, with most variations coming from the gauge (thickness) and material, the general process .

Welcome to contact with us if you have sheet metal parts want to custom make:Email: [email protected]: +86 13727008794#SheetMetalStamping#MetalStampi.Sheet metal is first placed through a rolling or expanding machine. Oscillating knife cuts the metal into an open mesh pattern. If flattened expanded metal is desired, then the expanded metal is cold-rolled through a flattener. With unflattened expanded metal, no secondary operation is performed and a louvered appearance remains. What Is Perforated Metal? Perforated metal is a form of sheet metal which has been punched or stamped with a machine to create a pattern of holes. It is also known as perforated sheet, perforated plate, or perforated screen and is commonly made from stainless steel, cold rolled steel, aluminum and more.. Perforated metal was first developed around 150 . HS35-200-1000G corrugated metal sheet roll forming machineماكينة تعريج صاجsupplied by LAROSA HARDWARE & EQUIP. CO. - SHARJAH U.A.Eمن شركة لاروزا للأدوات والم.

The manufacture of rolled/ galvanized/ color-coated steel sheet

in this video we will find answer to a common question :why GI sheets are made corrugated?What are the advantages and disadvantages of corrugation of Metal s. In this video, we explore how farmers in Pakistan are benefiting from affordable, durable steel sheets made from recycled rail steel. While the manufacturing. Stainless Steel 409 Sheets, Plates – 1.4512, X2CrTi12; Finish. Polished Stainless Steel Sheets; Mirror, 8K Stainless Steel Sheets; No.4 Finish Stainless Steel Sheets; No.4 Finish Stainless Steel Coils; BA Finish Stainless Steel Coils; .

which thickness called sheet metal

Copper sheet metal starts as a raw material, is smelted, then refined and cast into its final shape. Get the details on how copper sheet metal is made. 216.303.6475 Learn the steps of the metal stamping process, from product design all the way through delivery. This 7-step process includes design, die machining, processi.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

buying sheet would be fairly expensive (particularly copper sheet) and 2. just buying sheet would give me a lot of waste material that i would not be able to process. Casting the sheets means i could go to a scrapyard and pick up whatever metals .Aluminum sheets are used in various construction applications, ranging from roofing and siding to windows and doors. One of the main advantages of aluminum sheets in the construction industry is their lightweight nature. Aluminum is significantly lighter than other metals such as steel, making it easier to handle and transport.Various stacks of metal deck sheets. The metal deck sheets are silver, and the floor they are on is a gray color. Metal decking, sometimes referred to as steel decking, is a cold-formed corrugated metal sheeting that is formed into specific patterns of flutes and ridges.The deck is supported by joists or beams and supplies structural support for the insulating membrane of a roof.

The expanded metal mesh won't unravel because of its strong material properties. Even if the finished metal sheet is cut at one or more points, the remaining strand intersections can hold the sheet together. Five steps in the manufacturing process . The metal sheet advances between the blades one strand width beyond the lower.Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Select Size; 1 x 2 Ft. 1 x 4 Ft. 1 x 8 Ft. 2 x 2 Ft. 2 x 4 Ft. 3 x 4 Ft. 4 x 4 Ft. . How does roof sheet making machine works? Here is a factory tour for roof sheet former industry.Follow Us👇🔵FACEBOOK : https://www.facebook.com/factoryexplo.

Metal roofing panels are made of alloys of various metals such as steel, iron, copper, zinc and aluminum. Roll forming machine (used to make standing seam metal roofing sheet) is used in the workshop or on site. The steel is galvanised to provide adequate protection against the elements, as well as being corrosion resistant for a durable roof. Clickmetal is a specialist in the online supply of stainless steel, galvanised steel, mild steel and aluminium. We cut all types of metal to size and supply across the United Kingdom to both trade and domestic customers. Choose from our range of aluminium and steel products, including metal plates, bars, nosings and angles to name just a few.The ABM panel is made to custom lengths within a 1/4” thanks to what we call the “flying sheer.” The flying sheer cuts the steel with amazing precision as it speeds down the line. Step 6: Roll-Formed. The cut sheets go through a series of rollers . Sheet Metal Thinning Processes. Sheet metal is thinned to achieve the required size. Thinning aids in reducing sheet metal to the final dimension required for application. Metal sheets can still be thinner than 0.5 mm at the narrowest point to create metal foil. The thinnest steel sheet is a metal foil. The complicated reduction of sheet metal .

How Is Expanded Metal Made? Expanded metal is produced by an expanding machine, which turns solid metal sheets and coils into an expanded metal mesh. The expanding machine is fitted with a knife which determines pattern for the mesh. As the metal is fed through the expanding machine, it is cut and stretched simultaneously using a pressured .

sheet metal specifications

oem aluminum sheet metal stamping parts suppliers

oakwood metal fabrication

sheet metal process in impl

Browse photos of metal roof white house on Houzz and find the best metal roof white .

how metal sheets are made|sheet metal specifications