bearing cnc machine Factors to Consider When Selecting Spindle Bearings. CNC machine tool requirements; Load capacity and speed requirements; Rigidity and precision; Spindle bearing life; Environmental conditions; Lubrication options; . Zero-deflection box springs have slats that don’t flex, creating a firm and flat supportive surface that won’t add any additional bounce to your mattress. Semi-flex box .

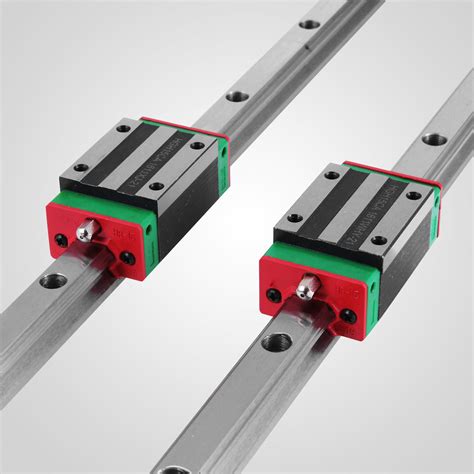

0 · linear rail and bearing block

1 · cnc supply store near me

2 · cnc machine bearing

3 · cheap linear bearings and rails

4 · cbc bearings near me

5 · cbc bearings catalogue

6 · cbc bearing company

7 · 1 2 inch linear bearing

If you're proficient at sneaking around guard patrols you shouldn't need it. They are useful in MGS1 though for transport if you need to backtrack, equip the appropriate box, sit still in an equipment truck and wait for a guard to deliver you to the location on the box.

CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance . Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high . Factors to Consider When Selecting Spindle Bearings. CNC machine tool requirements; Load capacity and speed requirements; Rigidity and precision; Spindle bearing life; Environmental conditions; Lubrication options; .Requirements on higher speeds and faster development results in very high demands on core parts of the CNC machine – especially the spindle units. With high running accuracy, high-speed performance and high system rigidity, SKF .

High rigidity thrust bearings designed specifically for ball screw support applications in machine tools. › Contact angle: 60˚ › Can be universally matched to any required rigidity specification or .

In Part 1 I discussed how selecting the right bearing configuration for a CNC machining center spindle can optimize performance. Improper installation or the use of the wrong bearing design and configuration can . CNC machine tools can work on almost all materials ranging from wood to titanium. So choose a tool that complements the rigidity of the material and offers a good amount of tolerance to maintain performance, durability, .

Machine spindles play a critical role in CNC machining, and selecting the appropriate ball bearing type is just as essential - each has its unique characteristics that make them suitable for different applications.Understanding the types of CNC bearings, their functions, and how to apply them in your CNC operation is crucial for your production success. Different bearings work on different CNC equipment, making it essential for you to choose them carefully.

linear rail and bearing block

There are four separate categories for bearings used in machine tool spindles. Each bearing design has characteristics that make it useful for certain applications, and it’s essential to know how each works so you choose the best bearing for your equipment.CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance tips, and troubleshooting techniques for spindle bearings, operators and manufacturers can optimize their CNC machine's performance and reduce downtime. Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy.

Factors to Consider When Selecting Spindle Bearings. CNC machine tool requirements; Load capacity and speed requirements; Rigidity and precision; Spindle bearing life; Environmental conditions; Lubrication options; Conclusion

Requirements on higher speeds and faster development results in very high demands on core parts of the CNC machine – especially the spindle units. With high running accuracy, high-speed performance and high system rigidity, SKF super-precision bearings are .

High rigidity thrust bearings designed specifically for ball screw support applications in machine tools. › Contact angle: 60˚ › Can be universally matched to any required rigidity specification or life cycle In Part 1 I discussed how selecting the right bearing configuration for a CNC machining center spindle can optimize performance. Improper installation or the use of the wrong bearing design and configuration can increase cycle time significantly, and may cause the entire machine to go down. CNC machine tools can work on almost all materials ranging from wood to titanium. So choose a tool that complements the rigidity of the material and offers a good amount of tolerance to maintain performance, durability, precision, and load-bearing capacity. Machine spindles play a critical role in CNC machining, and selecting the appropriate ball bearing type is just as essential - each has its unique characteristics that make them suitable for different applications.

Understanding the types of CNC bearings, their functions, and how to apply them in your CNC operation is crucial for your production success. Different bearings work on different CNC equipment, making it essential for you to choose them carefully. There are four separate categories for bearings used in machine tool spindles. Each bearing design has characteristics that make it useful for certain applications, and it’s essential to know how each works so you choose the best bearing for your equipment.CNC machine spindle bearings are crucial components for ensuring the accuracy, precision, and longevity of CNC machines. By understanding the importance, types, features, maintenance tips, and troubleshooting techniques for spindle bearings, operators and manufacturers can optimize their CNC machine's performance and reduce downtime. Precision Angular Contact Bearings - also known as Spindle Bearings - and are most often used in the main Spindle of CNC Machines and other Machine Tools. They can accommodate heavy axial loads at high speeds while maintaining running accuracy.

Factors to Consider When Selecting Spindle Bearings. CNC machine tool requirements; Load capacity and speed requirements; Rigidity and precision; Spindle bearing life; Environmental conditions; Lubrication options; ConclusionRequirements on higher speeds and faster development results in very high demands on core parts of the CNC machine – especially the spindle units. With high running accuracy, high-speed performance and high system rigidity, SKF super-precision bearings are .High rigidity thrust bearings designed specifically for ball screw support applications in machine tools. › Contact angle: 60˚ › Can be universally matched to any required rigidity specification or life cycle In Part 1 I discussed how selecting the right bearing configuration for a CNC machining center spindle can optimize performance. Improper installation or the use of the wrong bearing design and configuration can increase cycle time significantly, and may cause the entire machine to go down.

CNC machine tools can work on almost all materials ranging from wood to titanium. So choose a tool that complements the rigidity of the material and offers a good amount of tolerance to maintain performance, durability, precision, and load-bearing capacity.

metal sheet thickness

metal sheet precision stamping

There are different types of fabric glue available, including temporary bonds, permanent holds, flexible and repositionable options, and those that offer a strong and durable bond.Whether it’s DXF files for 2D drawings, DWG files for intricate designs, STL files for 3D modeling, or the all-encompassing G-Code files, each file type plays a significant role in ensuring the CNC machine’s optimal performance and the creation of precise, high-quality .

bearing cnc machine|cbc bearings near me