electric brewery control panel box Switch quality varies greatly from one manufacturer to another. After more .

What makes galvanized sheet metal a preferred choice for various industries? This article dives into the properties, types, and applications of galvanized sheet metal, revealing its effectiveness in rust prevention and durability. From hot-dip to electro-galvanized sheets, discover the different methods of galvanization and their specific .

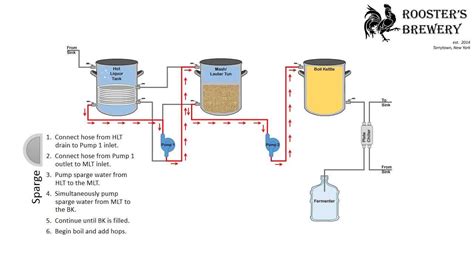

0 · herms brewing system diagram

1 · electric brewery systems

2 · electric brewery supply

3 · electric brewery recipes uk

4 · electric brewery control panel

5 · 15 gallon electric brewery

In this video I show you how to install an "old work" electrical box. I install this in a kitchen cabinet but the process is similar for other applications. I also discuss how "old work" and.

herms brewing system diagram

50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems. Up to .

50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 .50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 .Our temperature probes use 3-wire RTD (resistive thermal device) Pt100 sensors .

12 x 12 x 6 metal junction box

electric brewery systems

See our Electric Brewery Control Panel build instructions to build your own. .

Switch quality varies greatly from one manufacturer to another. After more .Our Standard 30A Electric Brewery Control Panel outlined here is perfect for .Used to implement the safe start feature found in our Electric Brewery Control .From home brewers to full-scale breweries, Electric Brewing Supply provides the highest quality brewing supplies & control panels for all your brewing needs.

"At the Brooklyn Brewery, we chose the Electric Brewery’s Control Panel for our pilot system as it allows us to have tight and repeatable controls throughout the brewing process, just like we do .

See our Electric Brewery Control Panel build instructions to build your own. Want to build something custom? Use the same quality parts that we use in our Control Panels!50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons of finished product per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems.Our Standard 30A Electric Brewery Control Panel outlined here is perfect for producing up to 20 gallons of finished product per batch. A single 5500W element is used in both the boil kettle and hot liquor tank.

Electric Brewing Supply introduces our own 30a PID control panel, capable of controlling either of 2x 5500w elements along with 2 pumps. The standard in HERMs brewing. Featuring a US made stainless enclosure and Electric .From our stainless steel enclosure to the Omron E5CC PID temperature controller and Omron H5CX timer. These panels are ready to go right out of the box. We have included an interlocking relay system that protects against dry .Save big on Grounded Brewing Technologies custom designed 30a electric BIAB (brew in a bag) control panel. We wanted to create a high quality panel without a high price tag. We have designed this panel from the ground up with quality in .

12 x 14 nema enclosure viking electric

Based on an industry standard touch control solution, the Ebrew 360 Series touch control panels are your most versatile solution in home brewing controls, with features and functions to include hot side as well as the cold side.

50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems. Up to two elements are used per kettle with one kettle powered at a time.

From home brewers to full-scale breweries, Electric Brewing Supply provides the highest quality brewing supplies & control panels for all your brewing needs.

"At the Brooklyn Brewery, we chose the Electric Brewery’s Control Panel for our pilot system as it allows us to have tight and repeatable controls throughout the brewing process, just like we do on our 50bbl production system.See our Electric Brewery Control Panel build instructions to build your own. Want to build something custom? Use the same quality parts that we use in our Control Panels!50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons of finished product per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems.Our Standard 30A Electric Brewery Control Panel outlined here is perfect for producing up to 20 gallons of finished product per batch. A single 5500W element is used in both the boil kettle and hot liquor tank.

Electric Brewing Supply introduces our own 30a PID control panel, capable of controlling either of 2x 5500w elements along with 2 pumps. The standard in HERMs brewing. Featuring a US made stainless enclosure and Electric Brewing's unique EBSP200 PID controller.From our stainless steel enclosure to the Omron E5CC PID temperature controller and Omron H5CX timer. These panels are ready to go right out of the box. We have included an interlocking relay system that protects against dry firing your heating .

Save big on Grounded Brewing Technologies custom designed 30a electric BIAB (brew in a bag) control panel. We wanted to create a high quality panel without a high price tag. We have designed this panel from the ground up with quality in mind.Based on an industry standard touch control solution, the Ebrew 360 Series touch control panels are your most versatile solution in home brewing controls, with features and functions to include hot side as well as the cold side.50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems. Up to two elements are used per kettle with one kettle powered at a time.

From home brewers to full-scale breweries, Electric Brewing Supply provides the highest quality brewing supplies & control panels for all your brewing needs."At the Brooklyn Brewery, we chose the Electric Brewery’s Control Panel for our pilot system as it allows us to have tight and repeatable controls throughout the brewing process, just like we do on our 50bbl production system.See our Electric Brewery Control Panel build instructions to build your own. Want to build something custom? Use the same quality parts that we use in our Control Panels!50A Electric Brewery Control Panel for 30+ gallons: For producing more than 30 gallons of finished product per batch or to speed up your brew day by reducing heat times. Perfect for 1-3 bbl pilot systems.

Our Standard 30A Electric Brewery Control Panel outlined here is perfect for producing up to 20 gallons of finished product per batch. A single 5500W element is used in both the boil kettle and hot liquor tank.Electric Brewing Supply introduces our own 30a PID control panel, capable of controlling either of 2x 5500w elements along with 2 pumps. The standard in HERMs brewing. Featuring a US made stainless enclosure and Electric Brewing's unique EBSP200 PID controller.

From our stainless steel enclosure to the Omron E5CC PID temperature controller and Omron H5CX timer. These panels are ready to go right out of the box. We have included an interlocking relay system that protects against dry firing your heating .

Save big on Grounded Brewing Technologies custom designed 30a electric BIAB (brew in a bag) control panel. We wanted to create a high quality panel without a high price tag. We have designed this panel from the ground up with quality in mind.

electric brewery supply

The H CNC code tells the machine to which height (H) offset to use with the current cutting tool. The value of the H offset is the distance between the end of the spindle and the end of the cutting tool.

electric brewery control panel box|electric brewery recipes uk