bending metal bracket quotes Tighten the spanner as much as posible and use it to grab the bent metal strip. The long handle will give plenty of leverage. You can even cover the spanner jaws with electrical tape or duct tape to protect the piece's finish. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

0 · the art of bending metal

1 · metal bending brackets

2 · l bracket bend

3 · how to bend a metal

4 · diy l bracket bend

5 · best metal bending tool

6 · bending sheet metal rules

7 · bending sheet metal parts

Choose from our selection of electrical enclosure vents, including snap-in breather vents, enclosure louvers, and more. In stock and ready to ship.

Making a sheet metal bracket involves a series of steps: selecting the appropriate metal, accurately measuring and marking your design, cutting the metal, bending it into the .There are a bunch of ways to bend metal for a bracket. Do a search on YouTube and you will likely find several techniques. Well, we do not want to disparage . Discover the art of bending sheet metal brackets and unleash your inner DIY guru! ? ️ Whether you're a seasoned pro or a total newbie, get ready to embrace the power of . Bending the Metal: To bend the cut metal into the desired bracket shape, use a vise, pliers, or a metal brake. For simple bends, pliers can be effective, while a vise provides stability for more pronounced angles. If your .

Tighten the spanner as much as posible and use it to grab the bent metal strip. The long handle will give plenty of leverage. You can even cover the spanner jaws with electrical tape or duct tape to protect the piece's finish. Making sheet metal brackets may seem like a daunting task but it doesn't have to be. With the right techniques and tips, you can turn your ideas into reality. In this comprehensive guide, we'll walk you through the steps .

The bracket plates were cut from a steel flat bar and have a slight bend to them. How can I bend these things straight? They seem "springy" and I've tried bolting them together tightly, but they . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

the art of bending metal

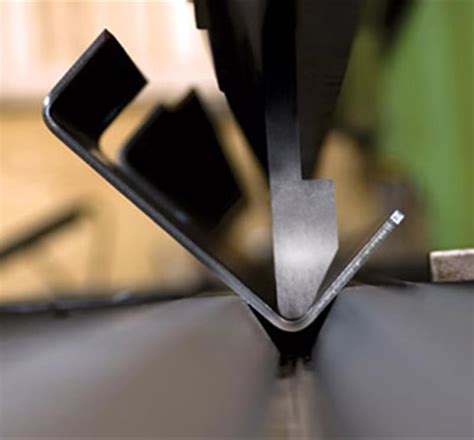

I have an L bracket and I need to bend it to be 45 degrees instead of 90 degrees. How can I do this without some serious tools? The L bracket was not welded to be 90 degrees, it was bent. Making a sheet metal bracket involves a series of steps: selecting the appropriate metal, accurately measuring and marking your design, cutting the metal, bending it into the desired shape, and finally, finishing and installing it. While this process demands precision, you can accomplish it with essential tools and some know-how. So, knowing the basics about bend allowances and bend deductions, you should be able to build your own custom steel enclosure, robot frame or mounting bracket using a brake press or the.

There are a bunch of ways to bend metal for a bracket. Do a search on YouTube and you will likely find several techniques. Well, we do not want to disparage any of those because they all have a place. Yet, we will throw in another – one that .

Discover the art of bending sheet metal brackets and unleash your inner DIY guru! ? ️ Whether you're a seasoned pro or a total newbie, get ready to embrace the power of metal as we dive. Bending the Metal: To bend the cut metal into the desired bracket shape, use a vise, pliers, or a metal brake. For simple bends, pliers can be effective, while a vise provides stability for more pronounced angles. If your design requires complex bends or precise angles, a metal brake is recommended, as it allows for greater accuracy and control. Tighten the spanner as much as posible and use it to grab the bent metal strip. The long handle will give plenty of leverage. You can even cover the spanner jaws with electrical tape or duct tape to protect the piece's finish. Making sheet metal brackets may seem like a daunting task but it doesn't have to be. With the right techniques and tips, you can turn your ideas into reality. In this comprehensive guide, we'll walk you through the steps necessary to make your own custom sheet metal brackets.

The bracket plates were cut from a steel flat bar and have a slight bend to them. How can I bend these things straight? They seem "springy" and I've tried bolting them together tightly, but they just spring back to their curved form. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. I have an L bracket and I need to bend it to be 45 degrees instead of 90 degrees. How can I do this without some serious tools? The L bracket was not welded to be 90 degrees, it was bent.

Making a sheet metal bracket involves a series of steps: selecting the appropriate metal, accurately measuring and marking your design, cutting the metal, bending it into the desired shape, and finally, finishing and installing it. While this process demands precision, you can accomplish it with essential tools and some know-how. So, knowing the basics about bend allowances and bend deductions, you should be able to build your own custom steel enclosure, robot frame or mounting bracket using a brake press or the.There are a bunch of ways to bend metal for a bracket. Do a search on YouTube and you will likely find several techniques. Well, we do not want to disparage any of those because they all have a place. Yet, we will throw in another – one that .

Discover the art of bending sheet metal brackets and unleash your inner DIY guru! ? ️ Whether you're a seasoned pro or a total newbie, get ready to embrace the power of metal as we dive.

Bending the Metal: To bend the cut metal into the desired bracket shape, use a vise, pliers, or a metal brake. For simple bends, pliers can be effective, while a vise provides stability for more pronounced angles. If your design requires complex bends or precise angles, a metal brake is recommended, as it allows for greater accuracy and control.

Tighten the spanner as much as posible and use it to grab the bent metal strip. The long handle will give plenty of leverage. You can even cover the spanner jaws with electrical tape or duct tape to protect the piece's finish. Making sheet metal brackets may seem like a daunting task but it doesn't have to be. With the right techniques and tips, you can turn your ideas into reality. In this comprehensive guide, we'll walk you through the steps necessary to make your own custom sheet metal brackets. The bracket plates were cut from a steel flat bar and have a slight bend to them. How can I bend these things straight? They seem "springy" and I've tried bolting them together tightly, but they just spring back to their curved form.

metal bending brackets

sloped junction box 45 degrees

l bracket bend

Our vertical mills provide high performance machining for a magnitude of applications. No matter your part, industry, or needs, there’s a Haas vertical machine perfect for your shop. Designed and manufactured in California by Haas, these spindles are custom-engineered for power, precision, and durability. Optimize your cutting conditions.

bending metal bracket quotes|bending sheet metal parts