bending sheet metal formula Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending . Learn about the American Welding Society's (AWS) Standard Welding Procedure Specifications (SWPS). Explore guidelines, procedures, and best practices for achieving welding excellence through SWPS documents.

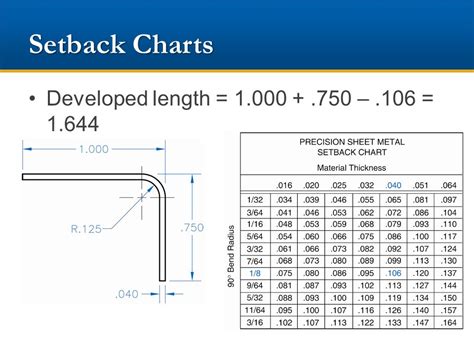

0 · sheet metal setback chart

1 · sheet metal flat length calculation

2 · sheet metal bending calculation formula

3 · sheet metal bending calculation excel

4 · sheet metal bending allowance chart

5 · how to calculate bending angle

6 · calculating bend allowance sheet metal

7 · bending calculation for sheet metal

See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables.

sheet metal setback chart

Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending .

sheet metal flat length calculation

sheet metal bending calculation formula

Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to .The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of .

Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate the value of bend deduction from the values of bend allowance and outside setback.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances.

7 axis cnc machine video

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses.There are two most widely accepted analytic representations of simple sheet metal bending. One representation is based on bend allowance and the other is based on bend deduction. The SolidWorks software as of this writing (up to SolidWorks 2000) employs the . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of .Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate the value of bend deduction from the values of bend allowance and outside setback.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances.

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses.

sheet metal bending calculation excel

If you have an original 755A with a tear -- fix it first!. As a last resort, these cones may be a 2nd chance for your 755A baskets, but, even with the original 3-4 ohm coil salvaged -- a different sound will be present, due to altered cone characteristics.

bending sheet metal formula|how to calculate bending angle