how to cut a cone shape out of sheet metal Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions. Unique Metal Fabrication, Inc., offers its customers a full range of services. In addition to an excellent team of employees, we have a superior line of equipment and machinery necessary to handle all types of structural steel and miscellaneous fabrication, providing everything our customers need to complete their projects within one operation.

0 · youtube sheet metal cone template

1 · sheet metal cone layout

2 · sheet metal cone formula

3 · sheet metal cone design template

4 · sheet metal cone design

5 · sheet metal cone chart

6 · sheet metal cone calculator

7 · making a cone from flat material

I bolt the boxes to the strut with a fender washer and put one of those square strut washers behind the box. It spaces it of enough that you don't need a kick if your strap is a mini.

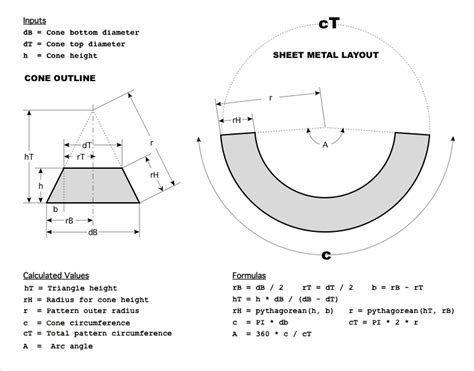

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone . Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

You will need: 1. Sheet metal (thickness and material of your choice) 2. Metal shears or a plasma cutter. 3. Metal brake or a hammer and anvil. 4. Welder (TIG, MIG, or oxy-acetylene) 5. Angle .

Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size . The cone has a diameter at the top smaller than the diameter at the bottom, and to accurately trace the shape onto sheet metal, you need to make a template out of construction paper. Lie your cone in the middle of a piece of . After a few days of head scratching, I figured out some fairly simple formulas to cut a cone of whatever size I want out of paper, plastic, or sheet metal. I'll go through my so-called thought process, but if you just want the .

Paragraph 1: If you're looking to create a cone shape from sheet metal, you've come to the right place. Fabricating a cone may seem like a daunting task, but . Draw the flat pattern of the cone on the sheet metal using .

Carefully cut along the lines using metal shears or a plasma cutter, ensuring you follow proper safety procedures. You should now have a sector of sheet metal that will form the cone. Step 3: Shape the Cone . To shape the cone, you will need to .How to Make a Cone: I use this method to make cones of a specific size, I mostly use it to make templates for metal or fabric. . Cut Out . I used scissors, but use what ever method works for you . Truncated Cone. here is the truncated . Learn how to convert a solid cone into sheet metal, and pattern a cut feature along a curve driven pattern at the flat pattern level.For more information abo. Step 2: Mark and Cut the Sheet Metal. Lay the sheet metal on a flat surface and mark a point in the center with a marker. Using the straightedge ruler and the center point as a guide, draw a circle on the sheet metal with a diameter equal to the base diameter you measured earlier. Next, use the tin snips to carefully cut out the circular shape.

The patern of the cones are a half circle cut out of a 13" wide strip of sheet metal. So the question is - is there a source of a simple machine that I have missed, or even possibly a trick of the trade that I am unfamilliar with. . Yes - The manual cone roller that I refered had cone shaped rollers, but seems not to be available. If you know .Cut out your cone template from the sheet metal using your tin snips, then file the edges smooth to avoid cutting yourself or someone else with the cone. Step 5 Roll the template into a cone shape, overlapping the sheet metal by 1/2 inch, then drill a few holes along the seam and seal it closed by placing rivets in the drilled holes. Cut two 1/3 circle shapes out of cotton fabric. . trace the bottom of the cone onto a spare sheet of material, then cut the circle out. Tape or glue the circle to the base of the cone. Thanks. . "Method 3 helped me determine the flat dimensions to make a cone out of metal for a jewelry project. :)" Charlie von Vimrod. Oct 23, 2021 .Still I feel like given the sheer amount of metalworking tools there ought to be a way to simply make a parabolic reflector shape if I could just figure out how. I suppose I could just cut out a "starfish" shape so to speak, and bend the individual "arms" up into a segmented parabolic shape, and weld the seams.

I am modeling the nosecone of the SpaceX starship and am trying to make a raised portion where the heatshield tiles are by unwrapping the nosecone shape, then cutting the required shape out. I have already done this on a cylinder, but I can't get fusion to unfold the nosecone shape.

youtube sheet metal cone template

sheet metal cone layout

How do you make a cone shape? How do you make a funnel with sheet metal?How do you make a flat material cone?How do you cut a cone shape out of sheet metal?h.

If you want tabs to fasten the flashing to the pipe, scribe a 3rd circle, 1/2" smaller than the center cutout. While you have your compass out, draw a circle on a piece of plywood with diameter equal to the desired finished cone. Cut the outer circle, cut a radial slit from the outside to the center and then cut out the center opening and any tabs.

There are many reasons that you might need to bend a cone from sheet metal. Metal cones are good for finishing chimneys, topping off certain types of outdoor fire and grill buildings and occasionally for decor purposes. . Cut this circle out with your sheet metal shears. Wear gloves for this, since the edges of the metal can be very sharp .

1 piece cone model the cone as a solidbody revolved 359.9deg. Convert to sheet metal by selecting an edge. Leaving the gap allows it to be converted to sheetmetal. 2 piece cone can be revolved 180 deg as a solidbody. Lofting cones does not .

Beginning with a plain piece of 22 gauge stainless steel sheet metal, I demonstrate how to roll a cone. One side of the roller is compressed more than the o. Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S.How to stamp a cone from sheet metal? I need to refine a DIY method of stamping the bottom of a soda can into a conical shape. Obviously a cone shaped anvil set will simply puncture the can bottom, so I suspect that the stamping has to be done . SolidWorks II Sheet Metal II Four Ways To Create Sheet Metal - ConeIn this video, I am going to explain Four difference ways to create Sheet Metal - Cone----.

Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th. There are many different ways to lay out this pattern. This is just one way and I find that is the easiest and quickest way. Enjoy.

Also, the tip of the cone is never going to form precisely right, so you really need to look at truncated cone to form it. If you are forming it by hand, good luck. That tip is going to be horrendously hard to do with out creasing your metal. The thinned you make it, the easier it will be to roll, but the more likely to crease at the tip.A cone, optionally with the top cut off. (In that case, it's called a frustum). Can be used to help create the geometry for a beaker, vase, party hat or lamp shade. If you'd like a real cone, just use 0(zero) for the Top Diameter. Do not score or fold the glue flap in this template to keep the geometry at the seam smooth. •you need a flat face for unwrapping, and that flat face can be extruded from a cut edge of a cylindrical or conical shape, using Join •you need to build your cylindrical or conical shape in the sheet metal environment. I've read and understood the 6 rules of Sheet Metal. But I can't figure out how to make a cone in Sheet Metal.

#MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late.Check out this channel (MECHBUZZ) - https://www.youtube.com/channel/UCg2nh83oJkc5nrvwIaV2aVQDownload 2d drawing here - https://drive.google.com/file/d/1Lb076.Making the Cone. Mark an 8-inch circle on a piece of sheet metal. Cut around the circle with tin snips and smooth the cut edges with sandpaper to remove all the burrs and sharp points. In the center of the circle measure a 2-inch circle and cut this out with the tin snips, once more smoothing the edge.

In this SolidWorks Sheet metal video tutorial you will learn how to make proper ellipse shape sheet metal part in solidworks by using sheet metal feature.Abo.

sheet metal cone formula

sheet metal cone design template

Steel double flood bracket allows for wood pole mounting of street and area lighting fixtures. LED and traditional fixtures can be utilized that slip fit onto the bracket. Available in hot dip galvanized (HDG), dark bronze, black, grey, white or natural aluminum finishes.

how to cut a cone shape out of sheet metal|sheet metal cone calculator