yield strength of sheet metal The strength of a metal is an important factor in determining its suitability for a particular application. Stronger metals can be used in structural applications, such as in the construction of buildings, bridges, and other infrastructure, where . There are a variety of styles of electric lunch boxes and many actually have adapters you can cook while you drive. I highly recommend electric lunch boxes for work because you can have a very hot meal and not have to wait for your turn to use a cleanliness-challenged microwave that is going to give you food that varies from hot to frozen in .

0 · steel grade yield strength chart

1 · steel grade strength chart

2 · sheet metal tensile strength chart

3 · metal shear strength chart

4 · material yield strength chart

5 · juning steel strength chart

6 · compression strength of metals chart

7 · 6mm steel strength chart

A pad-mounted transformer, also known as a green electrical box outside your house, transforms high voltage from power lines into lower voltage suitable for household use. They help deliver safe and reliable electricity to .

Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades . See moreStrength refers to the ability of materials to resist deformation and failure under the action of external forces. The main indexes can be divided into tensile strength (the . See moreMetal properties like steel yield strength, density, hardness and other parameters are important factors when designing a mechanical part or selecting the right material for CNC machining services, here we present a simple table of properties of some common metals and detailed metal mechanical properties chart. 1. Mechanical . See more Tensile / yield strengths and ductilities for some of the plain carbon and low alloy .

The strength of a metal is an important factor in determining its suitability for a particular application. Stronger metals can be used in structural applications, such as in the construction of buildings, bridges, and other infrastructure, where .Yield strength, minimum ksi 50 50-60 Phosphorus (P) 0.20 Tensile strength, minimum ksi 65 65-73 Manganese (Mn) 1.35 Elongation in 2 inch, minimum % 12 12-36 Sulfur (S) 0.04 Hardness, HRB 65-75 See ASTM A 653 for more details Supply Condition Standard Optional Fabricating Performance (1-Limited to 5-Excellent,

in making a part, whereas in high strength steels the yield and tensile strength level is the prime con-sideration. Higher strength steels are desirable for dent resistance, increased load carrying capability, improved crash energy management, or for mass reduction through a reduction in sheet metal thickness, or gauge.

The highest stress reached is known as the upper yield strength or upper yield point. Once a band of deformed (yielded) metal breaks free from being pinned by dislocations in the microstructure, the stress drops and there is an increase in strain. The lowest stress reached is known as the lower yield strength or lower yield point (Figure 3). In this guide, the terms “yield strength” refers to “tensile yield strength” rather than "compressive yield strength". Sheet metal parts. Source: Unionfab Why the Difference? Steel, like many materials, can withstand higher stresses in compression before yielding than in tension. This is due to the different ways materials fail under .5052 Aluminum, Alloy 5052H32 H34 Aluminum Sheet and Tube. 5052 aluminum is an Al-Mg series aluminum alloy with medium strength, high fatigue strength and good plasticity, and is the most widely used anti-rust material.Yield Strength and Ultimate Tensile Strength are not directly related to formability, however, the closer the magnitude of the two stresses, the more work hardened the metal. A work hardened metal exhibits lower ductility which reduces its ability to stretch. . Strain-rate sensitivity or speed of testing is very important in sheet metal .

Metal Type Tensile Strength (MPa) Yield Strength (MPa) Shear Strength (MPa) Compressive Strength (MPa) Hardness (HRC) Fatigue Strength (MPa) Impact Strength (Joules) Steel: 370: 220: 290: 340: 71: 210: 50: . we offering 5 and 3 axis,Laser Cutter,3D Printer,Sheet Metal Machine,Casting Machie,EDM,Injection Molding Machine,Forging Machine .Ultimate yield strength/yield stress is related to stress, not weight. With weight being a force, to equate that to stress you would find the force per area, using the thickness of the sheet. This is a little difficult in a realistic sense. Essentally you have a box with the floor being a steel sheet if I understand it correctly.Sheet thickness (in): Die edge radius (in): Punch edge radius (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety: The improvement in yield strength , or yield point, for metal formed parts bent transversely to the rolling direction is, for example, between 4 and 10% for spring steel 1.4310 with low strength (left graph) and up to 15% for high strength (right graph). This significant difference in the mechanical characteristics must be taken into account .

5. Sheet Metal Working »Sheet Metal Bending » Numerical Problem 05 20-10-2019 MEC323: PRIMARY MANUFACTURING (Dr. L K Bhagi) 5 A sheet-metal blank is to be bent as shown in Figure. The metal has a modulus of elasticity = 205 (103) MPa, yield strength = 275 MPa, and tensile strength = 450 MPa. Determine (a) the starting blank size and (b) the .

sheet closest to screw header or tension strength of screw. 8. Values are for pure shear or tension loads. See AISI Section E4.5 for combined shear and pull-over. 9. Screw Shear (Pss), tension (Pts), diameter, and head diameter are from CFSEI Tech Note (F701-12). 10. Screw shear strength is the average value, and tension strengthQuestion: Springback in a sheet-metal-bending operation is the result of which one of the following O yield strength of the metal overstraining elastic modulus of the metal overbending elastic recovery of the metal . Show transcribed image text. There are 2 steps to solve this one. Processing sheet metal materials from ultra-high-strength steels represents a promising and economically viable approach to produce sophisticated, light-weight car body structures [].Yet deep drawing of such dedicated high-strength steels poses a challenging task for manufacturers due to their limited formability, the high process loads during forming and the .A sheet-metal part that is 4.0 mm thick, 65 mm long, and 20 mm wide is bent in a V-die to an included angle of 60 degree and a bend radius of 7.5 mm. The bend is made in the middle of the 65 mm length, so that the bend axis is 20 mm long. The metal has a yield strength sigma_y = 220 MPa and a tensile strength sigma_TS = 340 MPa.

Annealed 304 stainless steel has a yield strength of approximately 200 MPa. 3003-H14 aluminium has a yield strength of 145 MPa. If your Al part needs to have equivalent strength to 3 mm thick 304 stainless steel, then the thickness would need to be t =(200 MPa/145 MPa) This article is aimed at simplifying the process of selecting suitable sheet metal materials for sheet metal fabrication projects. en – EU . Yield strength (MPa) Tensile strength (MPa) Elongation at break (%) Hardness: Modulus of elasticity (GPa) Aluminium 5052 / 3.3523 / AlMg2,5: 66 – 221: 173 – 269: 2 – 19:Study with Quizlet and memorize flashcards containing terms like 1. Sheet metalworking includes both forming and cutting operations: (a) True or (b) false?, 2. Typical sheet-metal thicknesses are between 0.4 mm (1/64 in) and 6 mm (1/4 in). When thickness exceeds the upper limit of this range, the stock is usually referred to as which one of the following: (a) bulk stock, (b) .YIELD STRENGTH OF STEEL. Yield strength values for common steels are given below. Yield Strength of Steel at Room Temperature: Material: Yield Strength: MPa: . Annealed sheet: 290: 42 (42000) AISI 316 Annealed bar: 240: 35 (34800) AISI 316 Annealed and cold-drawn bar: 415: 60 (60000) 17-7 PH RH950: 1030:

Consider a sheet metal of 5.00 in. width and 0.075 in thickness is to be rolled to a thickness of 0.050 in. in one pass using a mill whose steel rolls are of 8.00 in. diameter; the value of u in this case is about 0.10, and the yield strength of the metal before entering the roll is 20,000 psi. The work-hardening behavior of this metal is givenConsider a sheet metal of 5.00 in. width and 0.075 in thickness is to be rolled to a thickness of 0.050 in. in one pass using a mill whose steel rolls are of 8.00 in. diameter; the value of μ in this case is about 0.10 , and the yield strength of the metal before entering the roll is 20,000psi. The work- hardening behavior of this metal is .

Sheet metal with an average yield strength of 41,000 PSI can be sold as A36 steel, even though it is 13 percent harder than 36,000-PSI steel. This small variation might not seem like much, but the increased resistance to force requires more tonnage from the press brake in order to break the yield in the material and make it bend. When your .

Yield strength (YS) as reported on metal certs comes from the stress-strain curve generated during a tensile test. However, many details influence the reported value. Main Navigation . Technologies; End Markets . causing the line of missing atoms to move through the sheet. This is analogous to moving a carpet more easily by propagating a .

Tensile Strength 58,000-80,000 psi Min. Yield Strength 36,000 psi (Over 8" 32,000 psi) Elongation in 2" 23% *For each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to the maximum of 1.35% C1020 Hot Rolled Plate C1045 Hot Rolled Plate

Dimensional problems or springback have always existed in sheet metal forming. However, the magnitude of springback increases as the yield strength of the steel increases. As Advanced High-Strength Steel (AHSS) usage expands due to the combination of higher strength and ductility (for enhanced formability characteristics), countering springback relative to final part .ProFab Steel Solutions is a metal fabrication, production and assembly facility. Menu. About Us . 33ksi yield strength / 45 ksi tensile strength / paint-lock coating. 26ga. (30 mil.) – 33ksi yield strength / 45 ksi tensile strength / G-40 galvanized coating . Other Grades of Sheet Steel as specified or requested; G-90 Galvanized available .

lb electric box

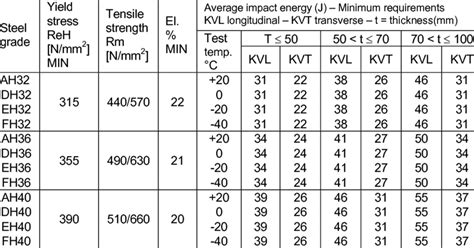

steel grade yield strength chart

steel grade strength chart

When you are choosing what type of barn roof to build, consider factors like weather, appearance, interior layout, maintenance, installation, and cost. 1. Gable Roof Barn. The gable roof is the classic roof shape that looks like a triangle. It also goes by the name “pitched roof” or “peaked roof.”

yield strength of sheet metal|steel grade yield strength chart