calculating bend allowance for sheet metal Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

OGONBRICK Universal Headboard Brackets Adjustable Base Headboard .

0 · sheet metal bending calculation formula

1 · sheet metal bending angle calculator

2 · sheet metal bending allowance chart

3 · sheet metal bend deduction calculator

4 · sheet metal bend allowance formula

5 · how to calculate bending allowance

6 · free bend allowance calculator

7 · bend allowance k factor chart

CNC stands for Computer Numerical Control, a manufacturing method that automates machine tools through preprogrammed software. CNC machines work by following instructions and parameters set in the program, .

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Effortlessly calculate K factor, Y factor, bend allowance, bend deduction, and unfold length in your metal fabrication projects. Unlock higher .

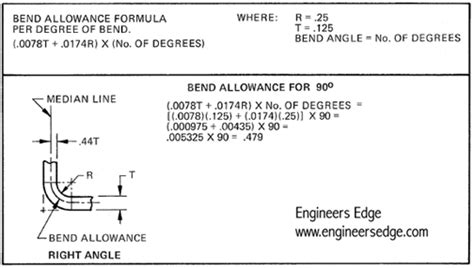

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend . By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent .Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors . It is very easy to calculate Bend Allowance if you have a formula for it. Below I have shared that formula. You just need to have the values for some required variables like Bend Angle, Inside Radius, K-factor, Material .

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

sheet metal bending calculation formula

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Effortlessly calculate K factor, Y factor, bend allowance, bend deduction, and unfold length in your metal fabrication projects. Unlock higher accuracy and efficiency - try it now!The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator. By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent dimensions. This is crucial for creating accurate flat patterns and ensuring that the bent part fits and functions as intended.

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors and optimizing material usage.

It is very easy to calculate Bend Allowance if you have a formula for it. Below I have shared that formula. You just need to have the values for some required variables like Bend Angle, Inside Radius, K-factor, Material Thickness, etc.

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Effortlessly calculate K factor, Y factor, bend allowance, bend deduction, and unfold length in your metal fabrication projects. Unlock higher accuracy and efficiency - try it now!

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator. By using the appropriate bend allowance formula or referring to reliable bend allowance charts, designers can accurately calculate the flat pattern dimensions of a sheet metal part that will yield the desired final bent dimensions. This is crucial for creating accurate flat patterns and ensuring that the bent part fits and functions as intended.

sheet metal bending angle calculator

Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors and optimizing material usage. It is very easy to calculate Bend Allowance if you have a formula for it. Below I have shared that formula. You just need to have the values for some required variables like Bend Angle, Inside Radius, K-factor, Material Thickness, etc.

corrugated sheet metal planter boxes

corrugated sheet metal loading table

Mount your Panhard bar with a precision machined JOES Panhard Mount. Just loosen the bolt (s) and slide the JOES Panhard. Steel brackets can be used as front mount for leaf spring or trailing arm. Dimensions: ⅝” Slot ³/₁₆” Thick 3¾” Locate your car’s third member securely with a pair of JOES 3rd Mounts. Made from 6061-T6 aluminum. Sold in pairs.

calculating bend allowance for sheet metal|sheet metal bend allowance formula