diy sheet metal flanger Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums. Electrical boxes, or junction boxes, are crucial components in electrical installations. Understanding the different types of electrical boxes and their specific uses is essential for anyone involved in electrical work or home improvement projects.

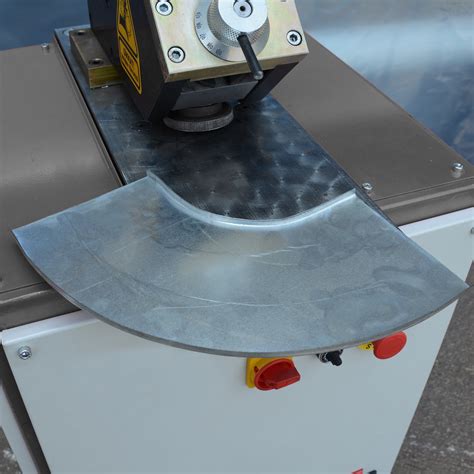

0 · sheet metal flanging machine

1 · pneumatic sheet metal hole punch

2 · pneumatic sheet metal flange tool

3 · harbor freight punch and flange

4 · hand sheet metal flanging tool

5 · flanging tool for sheet metal

6 · flange length in sheet metal

7 · automotive sheet metal flanging tool

G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

ceiling fan electric box is stripped

sheet metal flanging machine

#wurth #fertan #smėliavimasvarėnoje On this episode of Make It Kustom, I install a 1980s Jaguar gas cap in a 1948 Plymouth fender using simple tools to stretch the flange of the Plymouth sheet metal over the Jaguar gas cap structure. Follow along to learn how to . Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums.

pneumatic sheet metal hole punch

Had the need to form flanges on curved profile light gauge sheet metal recently, so made up this handy little tool to do the job, Using materials I had to hand, - see assembly and .

Flanging sheet steel involves adding a lip or bent edge to a sheet of metal to increase strength, facilitate attachment, or create a finished edge. This guide shows you how to flange metal. The Step-by-Step Procedure HOW-TO Make “REVERSE”CURVED FLANGES on SHEET METAL. In this episode, Karl makes a DIY stretcher tool from some scrap and a cheap tool from Harbor Freight. In a previous video he made a DIY shrinker .

Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork.I have a project that requires me to flange sheet metal to over lay another sheet. I don't have access to air so I can't just buy or rent a pneumatic tool. Is there any good hand tools/some .

Learn about a tipping die and the technique used to create curved bends on sheet metal panels, a very simple process.HOW-TO Make CURVED FLANGES on SHEET METAL. On this episode of Make It Kustom, I BUILD a shrinker tool from scrap metal Follow along to learn how to make your own sheet metal shrinking. #wurth #fertan #smėliavimasvarėnoje On this episode of Make It Kustom, I install a 1980s Jaguar gas cap in a 1948 Plymouth fender using simple tools to stretch the flange of the Plymouth sheet metal over the Jaguar gas cap structure. Follow along to learn how to make your own sheet metal flanging tool.

Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums. Had the need to form flanges on curved profile light gauge sheet metal recently, so made up this handy little tool to do the job, Using materials I had to hand, - see assembly and demo on the YouTube video below:-Flanging sheet steel involves adding a lip or bent edge to a sheet of metal to increase strength, facilitate attachment, or create a finished edge. This guide shows you how to flange metal. The Step-by-Step Procedure HOW-TO Make “REVERSE”CURVED FLANGES on SHEET METAL. In this episode, Karl makes a DIY stretcher tool from some scrap and a cheap tool from Harbor Freight. In a previous video he made a DIY shrinker from scrap he had laying around.

Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. I have a project that requires me to flange sheet metal to over lay another sheet. I don't have access to air so I can't just buy or rent a pneumatic tool. Is there any good hand tools/some easy home built method to flange sheet metal?Learn about a tipping die and the technique used to create curved bends on sheet metal panels, a very simple process.HOW-TO Make CURVED FLANGES on SHEET METAL. On this episode of Make It Kustom, I BUILD a shrinker tool from scrap metal Follow along to learn how to make your own sheet metal shrinking.

#wurth #fertan #smėliavimasvarėnoje

On this episode of Make It Kustom, I install a 1980s Jaguar gas cap in a 1948 Plymouth fender using simple tools to stretch the flange of the Plymouth sheet metal over the Jaguar gas cap structure. Follow along to learn how to make your own sheet metal flanging tool.Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums.

Had the need to form flanges on curved profile light gauge sheet metal recently, so made up this handy little tool to do the job, Using materials I had to hand, - see assembly and demo on the YouTube video below:-Flanging sheet steel involves adding a lip or bent edge to a sheet of metal to increase strength, facilitate attachment, or create a finished edge. This guide shows you how to flange metal. The Step-by-Step Procedure HOW-TO Make “REVERSE”CURVED FLANGES on SHEET METAL. In this episode, Karl makes a DIY stretcher tool from some scrap and a cheap tool from Harbor Freight. In a previous video he made a DIY shrinker from scrap he had laying around. Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork.

I have a project that requires me to flange sheet metal to over lay another sheet. I don't have access to air so I can't just buy or rent a pneumatic tool. Is there any good hand tools/some easy home built method to flange sheet metal?

pneumatic sheet metal flange tool

harbor freight punch and flange

ceiling fan doesn't mount to electrical box

ceiling fan box plastic or metal

The gear housing is a mechanical housing that surrounds the mechanical components of a gear box. It provides mechanical support for the moving components, a mechanical protection from the outside world for those internal components, and a fluid-tight container to hold the lubricant that bathes those components.

diy sheet metal flanger|automotive sheet metal flanging tool