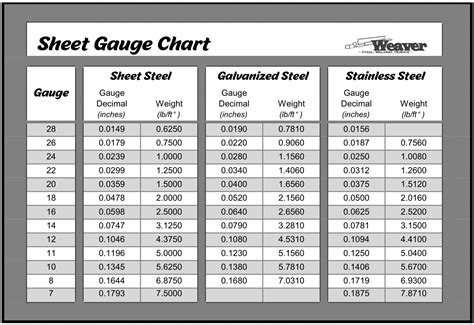

what gauge sheet metal should i use To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar . What is CNC Precision Machining? CNC precision machining refers to the use of Computer-Aided Manufacturing blueprints to shape raw material into desired products. It is a subtractive process involving the cutting excesses on various materials with different manufacturing processes. Precision CNC machining is now an essential part of the .

0 · 9 gauge thickness in inches

1 · 9 gauge diameter in inches

2 · 5 32 inch to gauge

3 · 15 gauge thickness in inches

4 · 15 gauge steel thickness

5 · 1.5 mm sheet metal gauge

6 · 1.2 mm thickness in gauge

7 · 1 8 sheet metal gauge

CNC stands for computer numerical control, a process of using software to control machines that can cut, carve, or engrave materials. Learn about different types of CNC .

To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar . Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless .

If you’re creating components from raw material, such as sheet or wire, you know how important it is to start with the right metal thickness (or gauge) for the item you’re making. . When you go to buy a sheet of silver you are going to have to select a “gauge”. This is the common measurement used here in United States. Gauge is a standardized measurement, the lower the gauge number the . The U.S. Standard Gauge for sheet and plate iron and steel, established by the Manufacturers’ Standard Gauge for Sheet Steel, is widely used in North America. Decimal Inch and Metric Equivalents: Modern manufacturing .

Gauges are used to specify the thickness of a sheet metal. Gauges are neither standard nor metric and the values are independent of those measurement systems. A gauge conversion chart can be used to determine .Here are a few key points to consider: Gauge Number: Locate the gauge number on the chart that corresponds to the sheet metal you are working with. This will help you determine its thickness. Thickness: Identify the thickness value .

This comprehensive explains the sheet metal gauge chart in the easiest yet very descriptive way. Choose the right gauge for your project.

0. How to Read a Sheet Metal Gauge Chart. IMS Team Metal University. Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet . What gauge of sheet metal should I use??? General discussion forum about the 240sx, and a great place to introduce yourself to the board! Post Reply Print view; Search Advanced search. 3 posts • Page 1 of 1. DerSimeon93 Posts: 7 . What is the correct gauge sheet metal that should be used? The contractor says he will use 26 gauge for supply and return trunks, and 30 gauge for branch runs? Is this the standard gauges for these? Reply . 11-25-2013, 10:13 AM #2. heaterman. View Profile View Forum Posts View Forum Threads .

A sheet metal gauge (also known as “gage”) determines the standard thickness of sheet metal for a particular material. The material thickness decreases as the gauge number increases. Steel sheet metal thickness gauges are based on a weight of 41.82 pounds per square foot and inch of thickness. What thickness is 16 gauge in this regard?

Mild steel sheet. 18 or 20 or 22 gauge. About for a 4'*4' piece. 22 gauge for new Hondas. 18 for old vw pans. 20 gauge for old vw bodies. It's a personal preference. 22 is way easier to bend than 18, but 18 will take more weld without blowing through. The stuff I get is light gray with an oil film, but black steel would work too ^This. Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. I used 16 gage flat sheet for a 24" x 43" trunk floor, but have two u-channel supports 12" apart in the center, and two smaller right angle iron pieces to help support the outer 18" or so.Get some practice in on some thin sheet scraps before you evaporate the metal in your tanks. 20 aguge is tough to learn on. Thoroughly wash out the tanks with boiling soapy water (use Dawn liquid soap). Repeat, then rinse with boiling (not just hot tap water) water.Metal gauge refers to the thickness of the metal sheets used in construction. The gauge of metal is measured in numbers, with a higher number indicating a thinner sheet of metal. Therefore, a higher gauge number may not be the best option for your barndominium. The most commonly used metal gauges for barndominiums are 26-gauge and 29-gauge.

For more rigid objects you are obviously going to need a thicker, or lower gauge, sheet metal. If the object contains different curves and needs to be pliable, then you will want to go with something a little thinner. The types of conditions that the object is exposed to will also influence the thickness of the sheet metal you choose.

Earrings 22 gauge sheet or 18 gauge to 12 gauge wire Pendants (design dependent) 18, 20, or 22 gauge sheet Backing for a bezel 24 gauge sheet OR 22-20 gauge sheet if the back plate is to extend beyond the bezel wire and have texture or embellishments on it. Related Reading: Sheet Metal Welding Guide: Weld 16, 20 and 25 or other Gauge Sheet Metal. Properly setting up the MIG welder is essential to produce high-quality welds and avoid issues such as weld spatter, poor penetration, or weld porosity. The problem with using the same gauge metal as the original is that when you grind down the welds, the remaining sheet metal can become paper thin. You have to be very careful when grinding. I learned to use thicker, 16 gauge, metal on some patches. This way I have extra metal to grind down and shape.

Then I sneak into my friend's welding shop and use his sheet metal brake when his back is turned. It is thick enough to weld with my wirefeed and .023" wire without any burn through. . Its an Auto Meter sender that needed minor tweaking but the gauge reads like its supposed to. This formula tells me how much it holds.25" long,,18.5" wide,,9.5 .

Question is what gauge of sheet metal should I use for floors & rocker panels? 22 gauge for fenders is my guess. Any info would be great . Save Share Reply Quote Like. Sort by Oldest first Oldest first Newest first Most reactions. ungermm. 1505 posts

Home Depot only sells 30ga sheet metal. That seems thin and flimsy to use for a plenum with slip and drive connections. What gauge metal to the pro's use? I'm assuming its something like 24 or 26ga and something I can only get at a building supply store? . You should use thicker gauge than 30 and cross break it Reply reply bob_bobington1234 . The reason I say thicker than 1/8 (though it would work fine) is that the metal that they use on the frames (if you have ever cut one in half or grinded on one much) is very clean very good metal. I don't think you will be able to go .Other parts of the world may use the British Standard Wire Gauge (SWG), where the sizes are just a hair larger than those of the AWG. (For example: AWG 20-gauge = 0.813mm and SWG 20-gauge = 0.914mm.) For the purpose of this article, all references below relate to the American Wire Gauge (AWG).

The local parts store carries 22 gauge steel panels that are something like 12x20", would these work to weld in if no replacements can be found? . If it's galvanized metal or e-coat,that will have to be ground down to bare metal to weld. Also, Try using smaller wire than 0.30 as it will weld a little easer and not as "hot" so you may not burn . I put 16 gauge floor panels in the one I'm working on now, with a framework of 3/4" 1/8"-wall square tubing to support it so there aren't any large spans of metal to act like noisy drum heads. On the other hand, 24-gauge metal roofing is still going to be more expensive than other, thinner options because of their thickness. 26-Gauge. The other most popular metal roof thickness, along with 24-gauge, 26-gauge panels (measuring between .0170 and .0217 inches) is the industry standard for most residential applications as well as .

hello i want to replace the floor pans on the bronco. many of you have changed your floor pans in the past, asking for your advise. some places sell 18 gauge metal floor pans. i am not sure as to how thick the metal should be. is 18 . Common Gauges for Automotive Sheet Metal. In the automotive industry, sheet metal gauges typically range from 18 to 22. Here’s a quick breakdown: 18 Gauge: About 0.048 inches thick, a good choice for heavier repairs where strength is essential. 20 Gauge: Roughly 0.0359 inches thick, often used for body panels and patching work. I use 20 gauge for smaller parts, for a whole floorpan 18 gauge won't need as much beading for strength. Now a related question; what are people paying for sheet metal? If I bring cash to the steel yard and don't need a receipt, I get a 4' X 10' sheet of 20 gauge hot rolled for . I think that is reasonable.

9 gauge thickness in inches

The most common gauges for metal roofing are 29, 26, 24, and 22 gauge. The vast majority of what we sell is either 26 gauge metal roofing or 24 gauge metal roofing. Low end agricultural jobs are normally 26 gauge or 29 gauge. While a beautiful new home with a standing seam roof would likely be 24 gauge.

For floors I'd use 16 or 18 gauge hot rolled pickled and oiled (HRPO) sheet. Pickling just removes the scale from hot rolled sheet and has no effect on hardness or workability. The oil is on it to prevent rusting prior to use. For the same thickness, hot rolled sheet is much easier to form than cold rolled because its softer. The original material there would be 20 gauge. 18 gauge would work there too. I also use metalsdepot.com for sheet metal. I usually order 2' x 2' pieces. Prices are the same to only barely higher than local when you figure in drive time and expense and cutting charges for small quantities. And you can't beat the convenience.Others might. You could use a 0-1" outside micrometer or vernier caliper and measure it, then get the nearest size from your sheet metal supplier. I would think clean scrap pieces would be fine (you won't need a 4x8' sheet will you?). If it's close to a standard thickness (16-20 gauge), your local home builder/hardware store might stock it. FYI:

Anyone know the sheet metal gauge for things like the floor pan, rocker panel and rear wheel wheels? I'm trying to get the right setting on my welder with some scrap, but I'm not sure what its supposed to be. Seems to be around 18-20 gauge . May 15, 2020 #2 bellaireroad Senior Member. Joined Dec 5, 2016 Posts 695

aircraft sheet metal mechanic resume

aiphone metal housing

An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. [1] Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

what gauge sheet metal should i use|1.5 mm sheet metal gauge