how to calculate bending allowance in sheet metal Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors . Deciding on metal roof types for your home? It's important to know all of your options. Learn more about 9 types of metal roofs and the pros & cons of each.

0 · sheet metal bending calculation formula

1 · sheet metal bending angle calculator

2 · sheet metal bending allowance chart

3 · sheet metal bend deduction calculator

4 · sheet metal bend allowance formula

5 · how to calculate bending allowance

6 · free bend allowance calculator

7 · bend allowance k factor chart

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .

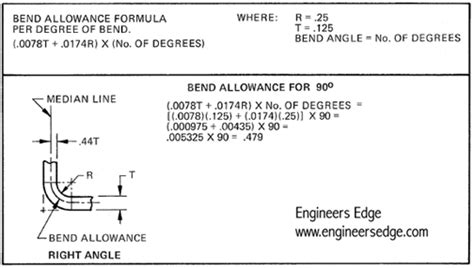

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

One of the easiest ways to calculate bend allowance is by using a bend allowance calculator. These calculators are designed to quickly and accurately compute the bend allowance based on the input parameters such as material type, thickness, bend angle, and bend radius.Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors .Bend Allowance Calculator. Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.This is a step-by-step guide. First, you need to determine the radius and bend angle. Use the following formula: Bend allowance = (p/180 x Bend angle x (Radius x K-Factor + Thickness). Angle is a critical component in calculating .

To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left. After bending the sheet, .

Bend allowance is the distance between the points where the metal is bent. This measurement determines how much material needs to be removed in order to create a . We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material.

How to Calculate Bend Allowance? After learning about bend allowance, the next step is to calculate it. Bend allowance is a critical factor in sheet metal fabrication, as it determines the amount of material needed to accommodate a bend. This ensures that the final dimensions of the .

Key Features. Accurate Calculations: Provides precise bend allowance and bend deduction values. User-Friendly Interface: Simple and intuitive design for easy use. Automatic Calculation: Real-time updates as you input values. Versatility: .

The following equation is used to determine the total flattening length when the bend allowance value is used: L t = A + B + BA. Where: 𝐿 𝑡 is the total flat length.; 𝐴 and 𝐵 are the lengths of the two straight sections of the sheet metal before the bend (as shown in the figure). Bend Allowance and Bend Deduction both values can be used to calculate the size of the flat pattern. But in this article, I will just cover the first term. Sheet Metal Bend Allowance. When a piece of sheet metal goes through the process of bending, its upper layer (with inside radius) is compressed and the lower layer (with outside radius) is .

Hi I've have not had that much experience of working with sheet metal. I have been asked to draw a simple bracket (see attached). I have used 2mm thk aluminium. I have been asked to supply the overall length of the flat pattern (which is no problem), and the bend allowance. How do I get this???? I've looked online and found a formula: bend . 4.0.4 How can I accurately calculate sheet metal bend allowances or deductions? 4.0.5 Why should I consider using Approved Sheet Metal's bend gains chart for my sheet metal fabrication projects? Let us calculate bend gains for you! Last updated on March 4th, 2024 at .

How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°. How to calculate bend allowance in sheet metal design and why is it important. What is Bend allowance in sheet metal? Let us consider a sheet metal bend with the following parameters. Bend allowance is the distance on the flat sheet before bending which will take up the radius after bend.

The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal. However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table. To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves creating a controlled deformation to form a . While bending produced metal parts, it results in wrong size of bent edges. How to calculate K-Factor in Inventor for Sheet Metal part? What is Bend Allowance? More material is stretch when is compresses, which lead in part being longer after bending

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.

Finally, to establish the bend line for the outer 90-degree bend, add up the outside dimensions of the previous flanges, subtract half a bend deduction for the outer 90-degree bend, a full hem elongation allowance for the flat hem, and a . CNC bending opens up laser cut sheet metal to a new world of possibilities, turning your 2D parts into 3D. To help make sure you get your bends the correct sizes and in the right places we’ve created a Bending Calculator .

How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.Below is our simple Bend Allowance Calculator, it works by inputing the Material Thickness, Bend Angle, Inside Radius and K-Factor. . Sheet Metal Bend Allowance Chart (Excel) BEND ALLOWANCE; 8 Gauge: 10 Gauge: 12 Gauge: 14 Gauge: 16 Gauge: 18 Gauge: 20 Gauge: 22 Gauge: 24 Gauge: K factor: 0.33: K factor: 0.33: K factor: 0.33: K factor:

In precision sheet metal manufacturing, the K-factor is a crucial factor. The K-factor is used to calculate the bending flat pattern, which is directly related to the length of the sheet metal stretched during bending. It is the fundamental value for determining the bending allowance and bending deduction. What is bend allowance for sheet metal? Bend allowance is a term used in sheet metal fabrication which refers to the amount of sheet metal needed for a bend. It is the length of the neutral axis between the bend lines, and it is used to calculate the flat pattern length of the sheet metal. Bend allowance is affected by the thickness of the . The sheet metal blank size is determined by considering factors like part dimensions, material thickness, bend allowance, stretch allowance, bend radius, minimum bend distance, material properties, K-factor, drawing ratio, setback, tooling, tolerances, part complexity, and material utilization efficiency. Accurate calculations ensure efficient use of material and .

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the arc length of the bend. Therefore, the bend allowance added to the flange lengths is equal to the total flat . Bend Allowance = (0.25 + 0.062) x 0.02 = 0.0062 inches. Conclusion. Determining the correct bend allowance for a sheet metal press brake is essential for achieving precise and accurate bends. By considering the material properties, bend radius, sheet metal thickness, and springback, you can calculate the appropriate bend allowance and ensure .Fabricators use these machines for precision and quick turnaround. However, small inputs and calculations are critical in achieving precise outputs. Among those, bend allowance calculation is of top priority. Underestimating the bend allowance will result in an inaccurate metal sheet size. Ironically, many people don’t know how to calculate it.

BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Calculator 2: Calculates Bend Deduction and Bend Allowance given bend angle, material . Note: There are a bunch of variables that play a roll on how much the neutral axis shifts in a bend metal. When a metal has more than one bend and/or bends in opposite directions, it changes the neutral axis location. Bend Allowance. The Bend allowance is the dimensional amount added to a part through elongation during the bending process.The importance of the 90 degree bend calculation lies in its ability to provide manufacturers with a quick and efficient way to calculate the necessary bend allowance for sheet metal bending. This calculation is essential in ensuring that the bend angle is . Flat-length calculator for sheet metal. To calculate the flat length of any sheet metal part, you can either calculate the bend allowance and add it to the total length or use the below formula. This formula holds good for most of the material but gives an approximate value. Flat Length = ((Π/2 )x R) + (Y x T))x ( A/90) Where,

sheet metal bending calculation formula

sheet metal bending angle calculator

With the variety of different electrical boxes available at home centers, how do you know what to buy? Don’t worry, it’s not that complicated. We’ll whittle it down to about a dozen boxes to cover almost every situation.

how to calculate bending allowance in sheet metal|sheet metal bend deduction calculator