how to develop a cone sheet metal Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone . UL 508A Listing is important to the municipal inspection authority and the purchaser of the panel, indicating that the control panel meets recognized safety standards for electrical equipment used in industrial settings.

0 · truncated cone from flat sheet

1 · sheet metal funnel layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone pattern calculator

4 · sheet metal cone layout calculator

5 · funnel pattern cut from sheet

6 · creating a cone layout

7 · cone layout calculator

"U" brackets, one ear brackets & 2 ear brackets in different materials and finishes to fit any installation. New construction, restorations and repairs Suitable for all metal, plastic laminate and wood toilet partitions.

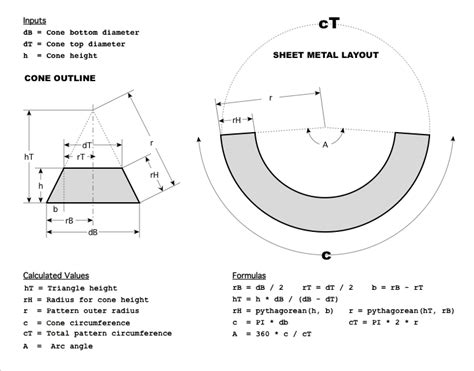

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number of gore sections to fit on . Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone .Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with . Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step .

The construction of 3-D models from pieces from flat cardboard or thin sheet metal requires some mathematical and geometrical application. Starting with simple 3-D forms, we can calculate the shape of the flat 2-D object needed to . Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I'm here to alleviate your worries and provide you with the correct workflow.Calculates the measurements for the pattern to construct a flat top cone.

How to develop a cone or how to create a flat pattern of a cone can be achieved in a few easy geometrical steps. The geometrical method shown below does however have inaccuracy, so at the end of this article I have . Thank you for watching this video . Like.Comment.& Subscribe for more NextGen CADD Videos.Please comment your opinion .share as much as possible.I use this method to make cones of a specific size, I mostly use it to make templates for metal or fabric. Step 1: Draw a Profile of the Cone You Want to Make Draw a profile of the cone you want to make.

Check out this channel (MECHBUZZ) - https://www.youtube.com/channel/UCg2nh83oJkc5nrvwIaV2aVQDownload 2d drawing here - https://drive.google.com/file/d/1Lb076.

truncated cone from flat sheet

Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th. Creating a Sheet metal cone in SOLIDWORKS can seem like a complex task, but I’m here to alleviate your worries and provide you with the correct workflow. I typically like to start my first sketch on the Top Plane. Using my sheet metal open sketch technique, we can draw an arc and its construction lines. With the radius (or diameter) dimension . SolidWorks Tutorial Sheet Metal Cone Tutorial video how to make cone in solidworks Learn how to layout a cone in sheet metal Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is.

Flat Top Cone Calculator. Calculates the measurements for the pattern to construct a flat top cone. Length A (mm) Length B (mm) Length C (mm) Arc Angle = _ (degrees) Radius R1 = _ (mm) Radius R2 = _ (mm) Join my newsletter to keep updated! 💌 .Learn how to create a truncated cone with this detailed guide. A truncated cone is a conical shape with its top cut off at an angle, often used in duct elements. Follow the instructions carefully to master this technique. . Sheet Metal Work. Interesting Drawings. Metal Fab. Ceramic Tools. Futuristic Background. Math Formulas. Geometric Drawing.

It is required to give this input while layouting Eccentric Cone. No. of development lines play a very important role in the accuracy of the layout so optimum no of development lines are needed to select. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar .

#MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Step 2: Mark and Cut the Sheet Metal . Now that you have your dimensions, it's time to mark and cut the sheet metal. Using a compass or trammel, draw a large circle with a radius equal to the slant height (L) on the sheet metal. Then, draw a smaller circle within the larger circle, with a radius equal to the top radius (R2). This Solidtec - SolidWorks tip demonstrates how to produce a Sheet Metal cone in SolidWorks using the Lofted-Bend tool, then export the flat pattern to dwg o.

20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the . Developing a pattern for a cone with a pitch using radial line development . What's important to remember with radial line development is all tapers (slants) must remain constant. (Left). First step, draw an elevation view . Sheet metal cones are versatile and indispensable in a wide range of applications, from ductwork in HVAC systems to chimney caps and funnels. Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step-by-step guide, we will walk you through the . This Video Demonstrates the Cone Flat-Pattern Capabilities of Solidworks Sheet Metal By KRISHANTHA PRADEEP

Step 8: Benefits of Fabricating a Cone From Sheet Metal. There are several benefits to fabricating a cone from sheet metal, including: Sheet metal is durable and can withstand harsh environments. Sheet metal cones can be made to exact dimensions, ensuring a perfect fit for any application. Sheet metal cones are lightweight and easy to transport. Metal domes are often spun (watch Youtube for Spun Metal) but you don't really have much of a dome there, it's more of a heavily filleted cone. The method Reis describes what armorers use and that is what you need here since it's actual (fantasy) armor. With these methods you can get the whole shape from one sheet if you are skilled.

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt. Learn how to convert a solid cone into sheet metal, and pattern a cut feature along a curve driven pattern at the flat pattern level.For more information abo. Using the Flat Pattern Cone Calculator App makes it quick and easy to draw any cone in minutes.In this video I will draw a Concentric Reducer Cone. Flat patt.Locate a radius point where you want to develop the pattern. With your compass, take the slant height from the elevation view and swing an arc ( stretch-out arc ). Establish a starting point for the pattern and draw a line back to the radius point.

Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", .This generates the development for the cone, which is a sector of a circle with radius R and sector angle θ. To calculate the dimensions of the development, first the slant height of the cone must be found from Pythagoras' theorem, . A scalene cone made in sheet metal is shown above.

Learn how to develop a cone with this step-by-step guide. Get insights into cone development and create a flat pattern of a cone in easy geometrical steps. Perfect for those interested in sheet metal, sheet metal fabrication, geometric drawing, metal bending tools, and sheet metal work.

sheet metal funnel layout

This organization is not BBB accredited. Sheet Metal Fabrication in Bozrah, CT. See BBB rating, reviews, complaints, & more.

how to develop a cone sheet metal|sheet metal funnel layout