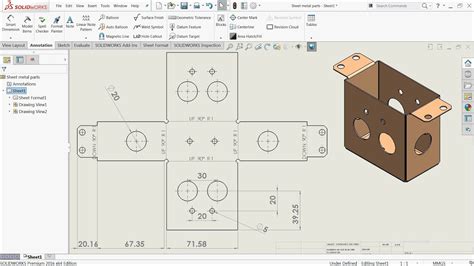

sheet metal drawing and pattern development Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when .

Peruse our collection of Metal and Copper Liners, featuring galvanized metal and copper options available in extensive standard sizing. Enjoy free shipping on all orders for added convenience.

0 · simple sheet metal drawings

1 · sheet metal pattern layouts pdf

2 · sheet metal pattern layout methods

3 · sheet metal layout drawings

4 · sheet metal drawing templates

5 · sheet metal development drawing pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

$6.35

Sheet metal drawing and pattern development : Dickason, A. (Alfred) : Free Download, Borrow, and Streaming : Internet Archive. by. Dickason, A. (Alfred) Publication .

A line drawing of the Internet Archive headquarters building façade. An .

A line drawing of the Internet Archive headquarters building façade. An illustration of a computer application window Wayback Machine An illustration of an open book. . sheet metal drawing and pattern development by a. .A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. . Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in .

Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when .Triangles (A-B-C), squares or rectangles (A-B-C-D), and circles are some of the most common shapes seen in the sheet metal industry. It is a combination of points, lines, and angles that . Found a matching Library of Congress MARC record. April 1, 2008. Created by an anonymous user. Imported from Scriblio MARC record. Sheet Metal Drawing & Pattern .Sheet Metal Drawing and Pattern Development. Alfred Dickason. Pitman, 1967 - Sheet-metal work - 364 pages.

simple sheet metal drawings

Sheet Metal Drawing & Pattern Development by Alfred Dickason, February 1983, Sportshelf & Soccer Associates edition, Paperback in English Sheet Metal Drawing & Pattern Development by Alfred Dickason, 1967, Pitman edition, in English. It looks like you're offline. Donate ♥. Čeština (cs) Deutsch (de) English (en) Español (es) Français (fr) .architect's scale, 12"; 4H drawing pencil; pencil erasing rubber; thumb tacks; detail paper; also a set of drawing instruments consisting of the following items: 5" dividers, 5 1/2" compasses, 3" bow spacers, 3" bow pencil, ruling pen, bow pen and irregular curves. Paper. The paper generally used for sheet-metal pattern drafting is

sheet metal pattern layouts pdf

The rest of this section will focus on sheet metal specific drawing considerations and best practices. Sheet metal specific drawing items Flat pattern views. All drawings need orthographic views to represent 3D geometry generally. In .Getting the flattened pattern of sheet metal fabrication parts by hand is time consuming, requires lots of knowledge, and it is prone to errors and not reliable.. There are lots of good sheet metal pattern development software programs out there, but they are expensive, with high subscription fees, with complex hardware requirements, and extensive user knowledge.

Draw a full front elevation view and end elevation view (right side). Notice that the tee does not go passed centre of the pipe, it never will. Because of that, we can delete that portion of the drawing. Draw profiles on the tee in both views and divide into 6 equal parts (see Divide a Circle Into 12 Equal Parts). Include all labeling.The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is likely to come up in practice and explaining the selection and use of drawing tools and linear and geometrical drawing so clearly that one who has had no .

Buy Sheet Metal Drawing and Pattern Development 6 by Dickason, A. (ISBN: 9780273411635) from Amazon's Book Store. Everyday low prices and free delivery on eligible orders. Sheet Metal Drawing and Pattern Development: Amazon.co.uk: Dickason, A.: 9780273411635: BooksSheet Metal Drawing & Pattern Development by Alfred Dickason, February 1983, Sportshelf & Soccer Associates edition, Paperback in English22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.

Flat Pattern (FP): It is the planar drawing of the blank required to form the desired sheet metal component. Flat Pattern Development (FPD): It is the process of determining flat pattern for a sheet metal component corresponding to its neutral surface. The neutral surface is the surface within the sheet that is parallel to the inner andStudy with Quizlet and memorize flashcards containing terms like sheet metal industry and packaging industry, sheet metal industry, packaging and more. . Pattern Development- Drawing. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. . A flat pattern or development used in laying out, cutting and folding lines on flat stock.Draw an Arc Through Three Points 25 9. Divide a Circle Into 12 Equal Parts 29 10. Divide a Line Using a Ruler on an Angle 31 11. . Pattern Development: Sheet Metal Level 1. and • . • . About BCcampus Open Education . Pattern Development: Sheet Metal .

Buy Sheet Metal Drawing and Pattern Development New by Dickason, A. (ISBN: 9780582994829) from Amazon's Book Store. Everyday low prices and free delivery on eligible orders. Sheet Metal Drawing and Pattern Development: Amazon.co.uk: Dickason, A.: 9780582994829: BooksSheet Metal Drawing and Pattern Development-A.Dickason-The Holy Grail of Sheet Metal Developement.For the Tradesman/Designer there is none Better. Like. Comment. Displaying 1 of 1 review. Join the discussion. Add. a quote. Start. a discussion. Ask. a question. Can't find what you're looking for? Get help and learn more about the design. Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. . It .

different distributions box plot

Draw an elevation view, complete with the miter line. Draw a profile below (see Divide a Circle Into 12 Equal Parts) and label it. Project the profile divisions up into the elevation view. Draw the stretch-out (6 × Pi) directly to the right of the elevation view and divide it into 12 equal parts (see Divide a Line Using a Ruler on an Angle).

If we think back to geometric construction, we created triangles such as a 3-4-5 in this manner. The development of patterns using triangulation is an extension of that process. Developing one triangle after another, we build 2D patterns for 3D objects. In this unit, we will focus on Triangulation from plan view. Both software options provide specialized tools for sheet metal-specific operations, such as bend deductions, flat pattern development, and automatic generation of production-ready drawings. Parametric CAD tools ensure that any design changes are cohesively reflected throughout the model and drawings, thereby enhancing design accuracy and .A sheet metal pattern is a(n) _____ drawing of the object. stretchout. Sheet metal patterns are also known as _____. prism and cylinder . pyramid and cone _____ and _____ are examples of the radial-line pattern development. Used to connect two differently shaped openings. What purpose does a transition piece serve? .

Pattern Development: Sheet Metal Level 1 Line E Brian Coey BCCAMPUS VICTORIA, B.C.

The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is likely to come up in practice and explaining the selection and use of drawing tools and linear and geometrical drawing so clearly that one who has had no .Study with Quizlet and memorize flashcards containing terms like Sheet metal pattern, Parallel line development, Transition piece and more. Study with Quizlet and memorize flashcards containing terms like Sheet metal pattern, Parallel line development, Transition piece and more. . A full size drawing of the surface of the object stretched out .

In Parallel Line Pattern Development, we required parallel element line or bends. Some objects are of a conical shape and parallel line will not work on them. Rather, we will look at using Radial Line Pattern Development. In radial line, we develop patterns for shapes that have a taper, all element lines (bends) must radiate back to a common .

20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.Make sure the fitting is sized correctly. Remember some of the sizing rules for y-branches: the crotch height must be ¾ of the base diameter (or 1.5x the radius), the small openings must equal the large- A2 + B2 = C2 can be used to size the fitting correctly Draw a complete elevation view of 1 side of the fitting. The second side would be traced or a second pattern would be developed .

Development Pattern Construction: CONSTRUCTING DEVELOPMENT SHAPES WITH MATHEMATICS The construction of 3-D models from pieces from flat cardboard or thin sheet metal requires some mathematical and geometrical application. Starting with simple 3-D forms, we can calculate the shape of.Oct 27, 2023 - Explore Shaun Wing's board "Sheet Metal Pattern Development" on Pinterest. See more ideas about sheet metal, sheet metal fabrication, sheet metal work. . Sheet metal drawing. Metal working tools. Interesting drawings. Geometric drawing. Press Brake Tooling. Metalworking Projects. Folding Machine. Metal Shaping.

sheet metal pattern layout methods

A wire-cut EDM machine using the CNC drawing plotter and optical line follower techniques was produced in 1974. Dulebohn later used the same plotter CNC program to directly control the EDM machine, and the first CNC EDM machine was produced in 1976.

sheet metal drawing and pattern development|free sheet metal layout patterns