bend tables for sheet metal materials To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of . We discussed the various types of electrical box screws, including machine screws, self-tapping screws, wood screws, drywall screws, and anchor screws. We also provided insights into the recommended screw sizes for different box types, such as outlet boxes, switch boxes, junction boxes, and ceiling boxes.

0 · stainless steel bend chart

1 · solidworks sheet metal round bend

2 · solidworks k factor bend table

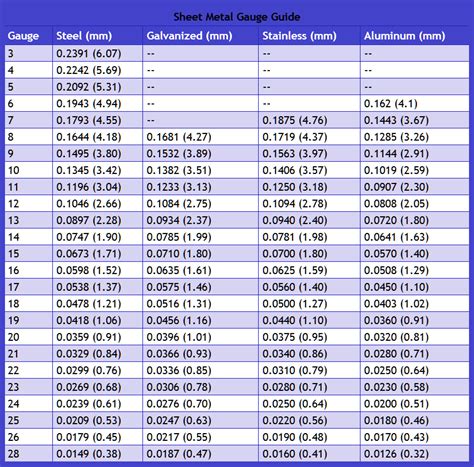

3 · sheet metal gauge chart excel

4 · sheet metal bending radius chart

5 · sheet metal bend solidworks

6 · sheet metal bend chart

7 · sheet metal bend allowance table

It’s more of the way Glam doesn’t seem to remember the contents of the box then, begins to dissociate upon seeing them, the distinct differences between him as “Sebastian” and “Glam,” the moment he was having a monologue in his head that suddenly switched gears to a completely different, silently furious tone, that you could .

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend .

To create your own bend table, copy and edit this bend table with any text editor. .Sheet metal gauge/bend tables store properties for a designated material. A .To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of .A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the .

In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data. By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the .

Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend radius; k-factor = k-factor (you can use an equation or a value)

To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of measure in the Unit row of the bend table.A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the table, the flat pattern analyzer interpolates between adjacent cells to determine a value. In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data.

By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the material readily available.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.Sheet metal bend tables allow you to specify a sheet metal part’s bend allowance or bend deduction values. The bend table also includes bend radius, bend angle, and part thickness values. Bend tables are accessible in text files and Microsoft Excel spreadsheets.

Accurate bend deductions are key to delivering high-quality sheet metal parts. To streamline your design process and ensure your parts are manufactured without delays, we’ve created easy-to-use bend deduction tables specifically for our shop’s equipment and processes.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. You can also use individual gauge tables and bend tables. See Sheet Metal Gauge Table and Bend Table Overview.You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. . s = material thickness; r = bend radius; k-factor = k-factor (you can use an equation or a value)To create your own bend table, copy and edit this bend table with any text editor. All bend table types (bend deduction, bend allowance, and k-factor). All units of measure (meters, millimeters, centimeters, inches, and feet). Set the unit of measure in the Unit row of the bend table.

A bend table specifies the bend allowance for a specified material thickness at specific radii, and bend angles for the flat pattern analyzer. If a specific bend angle or bend radius is not in the table, the flat pattern analyzer interpolates between adjacent cells to determine a value. In this tech tip post learn how to create your own SOLIDWORKS Sheet Metal Bend Table for Bend Allowance, Bend Deduction and K-Factor data.

By setting up a sheet metal gauge table for your project, it can dramatically speed up your workflow by making the selection of the bend radius and the right wall thickness of the material readily available.Sheet metal gauge/bend tables store properties for a designated material. A single table lets you associate a bend allowance, bend radius, or k-factor with any combination of thickness, bend radius, and material. In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples.Sheet metal bend tables allow you to specify a sheet metal part’s bend allowance or bend deduction values. The bend table also includes bend radius, bend angle, and part thickness values. Bend tables are accessible in text files and Microsoft Excel spreadsheets.

Accurate bend deductions are key to delivering high-quality sheet metal parts. To streamline your design process and ensure your parts are manufactured without delays, we’ve created easy-to-use bend deduction tables specifically for our shop’s equipment and processes.

stainless steel bend chart

electrical box for ceiling light fixture

When I box a old chassis, I use .125" (1/8") plate, UNLESS it's going to be a chassis that's going to get a motor that makes big-torque or if it's going to be beat on, then I use 3/16".

bend tables for sheet metal materials|sheet metal gauge chart excel