coolant used in cnc machine Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. . During our investigation, I discovered an abandoned shipment through a Diplomat from United Kingdom which was transferred from JF Kennedy Airport to our facility here in Atlanta, and when scanned it revealed an undisclosed sum of money in 2 Metal Trunk Boxes weighing approximately 110kg each.

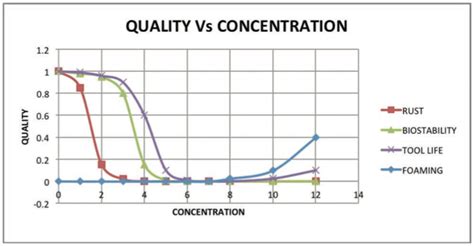

0 · machine coolant concentration chart

1 · coolant system in cnc machine

2 · coolant system for milling machine

3 · coolant concentration for cnc machines

4 · cnc machine coolant suppliers

5 · cnc machine coolant health problems

6 · cnc machine coolant disposal

7 · best coolant for cnc machines

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal . Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. . Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid . CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the .

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining . CNC machining coolant mitigates these risks by efficiently dissipating heat to reduce tool wear, and improve overall machining precision and accuracy. What Happens if You Don’t Use Coolant When CNC Machining? What is CNC Coolant? CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal . The role of coolant in CNC machining is essential for maintaining tool life, achieving the desired surface finish, and ensuring overall process efficiency. This comprehensive guide will delve into the various types of .

Coolant in purpose is widely understood – it’s used to temper high temperatures common during machining, and aid in chip evacuation. However, there are several types and styles, each with its own benefits and drawbacks. Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and . It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal concentration, consider the specific operation at hand. Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. Learn about coolant types, formulations, and why consistent application is essential for optimal machining outcomes.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the cutting tool at low speeds.

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process. CNC machining coolant mitigates these risks by efficiently dissipating heat to reduce tool wear, and improve overall machining precision and accuracy. What Happens if You Don’t Use Coolant When CNC Machining? What is CNC Coolant? CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface. The role of coolant in CNC machining is essential for maintaining tool life, achieving the desired surface finish, and ensuring overall process efficiency. This comprehensive guide will delve into the various types of coolants available, their benefits, and best practices for coolant selection and management in CNC machining.

Coolant in purpose is widely understood – it’s used to temper high temperatures common during machining, and aid in chip evacuation. However, there are several types and styles, each with its own benefits and drawbacks. Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and . It’s not merely about pouring coolant into your CNC machine, but about finding that ‘sweet spot’ where your coolant concentration provides optimum cooling, lubrication, and chip removal. To establish the ideal concentration, consider the specific operation at hand.

Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. Learn about coolant types, formulations, and why consistent application is essential for optimal machining outcomes. Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the cutting tool at low speeds.

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process. CNC machining coolant mitigates these risks by efficiently dissipating heat to reduce tool wear, and improve overall machining precision and accuracy. What Happens if You Don’t Use Coolant When CNC Machining? What is CNC Coolant? CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface. The role of coolant in CNC machining is essential for maintaining tool life, achieving the desired surface finish, and ensuring overall process efficiency. This comprehensive guide will delve into the various types of coolants available, their benefits, and best practices for coolant selection and management in CNC machining.

how to wire an inverter into home distribution box

machine coolant concentration chart

coolant system in cnc machine

coolant system for milling machine

$79.99

coolant used in cnc machine|best coolant for cnc machines