advantages cnc machines Computer numerical control machining’s advantages make it the preferred manufacturing method for several industries, such as medical equipment, automobile and aerospace. This manufacturing process can . I'd say cast your self a 1'X1'X1' solid concrete block with a piece of 1-1/2" PVC pipe used to form a hole all the way through the middle. Get a piece of logging chain and/or a very good bike cable and a solid lock, not one made of layers .

0 · disadvantages of cnc machines

1 · disadvantages of cnc

2 · cnc punching machine disadvantages

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · advantages of cnc milling machine

This field is for validation purposes and should be left unchanged. Δ. © 2024 Utility Metals

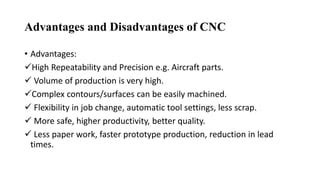

CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. .

Computer numerical control machining’s advantages make it the preferred manufacturing method for several industries, such as medical equipment, automobile and aerospace. This manufacturing process can . While there are advantages to both, CNC machining is faster and stronger as it involves creating something new out of an already solid material. CNC machine programming . Computer Numerical Control (CNC) technology automates machine tools through computer programming. It allows precise control over movements and operations, enabling . CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over . CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. 3) Cost-effective: It reduces the labor cost and increases the production efficiency. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

Computer numerical control machining’s advantages make it the preferred manufacturing method for several industries, such as medical equipment, automobile and aerospace. This manufacturing process can deliver highly precise made-to-order parts. While there are advantages to both, CNC machining is faster and stronger as it involves creating something new out of an already solid material. CNC machine programming offers many production advantages over previous methods of machining and is an indispensable tool across many industries. How CNC Machines Work? Computer Numerical Control (CNC) technology automates machine tools through computer programming. It allows precise control over movements and operations, enabling machines to execute complex tasks with high accuracy. CNC systems typically consist of a computer, software, and a machine interface. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over traditional machining tools. CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. 3) Cost-effective: It reduces the labor cost and increases the production efficiency. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

Computer numerical control machining’s advantages make it the preferred manufacturing method for several industries, such as medical equipment, automobile and aerospace. This manufacturing process can deliver highly precise made-to-order parts. While there are advantages to both, CNC machining is faster and stronger as it involves creating something new out of an already solid material. CNC machine programming offers many production advantages over previous methods of machining and is an indispensable tool across many industries. How CNC Machines Work? Computer Numerical Control (CNC) technology automates machine tools through computer programming. It allows precise control over movements and operations, enabling machines to execute complex tasks with high accuracy. CNC systems typically consist of a computer, software, and a machine interface. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

cnc machining in ohio

disadvantages of cnc machines

disadvantages of cnc

cnc punching machine disadvantages

Using steel wood to polish wood might seem out of place and actually harmful to the surface of the wood, but it isn't if done properly. The steel wool is very fine and will actually scrape off a very fine layer, leaving a silky .

advantages cnc machines|cnc punching machine disadvantages