electrical code for receptacle box installation on extension drywall Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this . Boxes 14 – 19 show state and local tax withholdings as well as the part of the distribution reported to the state.

0 · receptacle box wiring requirements

1 · receptacle box wiring instructions

2 · receptacle box wiring codes

3 · receptacle box cable installation code

4 · receptacle box cable codes

5 · installing electrical boxes in drywall

6 · electrical box installation codes

7 · depth of drywall electrical box installation

Make sure you use shielding gas and not flux core wire. Don't waste your money on the CJ-5 panel if you are just going to cut it up to patch some rust holes. Get some pieces of sheet metal the same gauge as the existing body panel, probably 18 -22 gauge steel (but I doubt it's as thick as 18) Practice on the sheet before starting in on the Jeep.

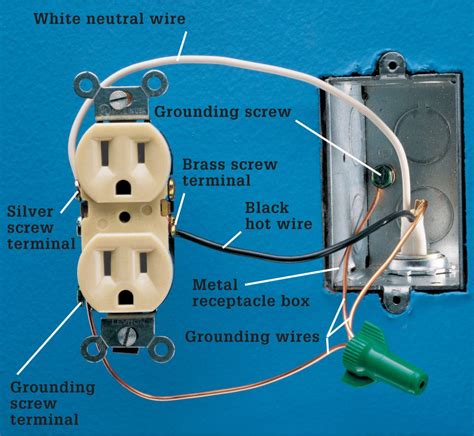

The electrical cables that run through walls and in and out of electrical boxes must be both supported and installed with adequate lengths .In walls and ceilings constructed of wood or other combustible surface material, boxes, plaster rings, extension rings, or listed extenders shall be flush with the .Receptacles mounted in boxes that are set back from the finished surface as permitted in 314.20 shall be installed such that the mounting yoke or strap of the receptacle is held rigidly at the finished surface.

purple pet stainless steel litter box

Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this . Installing box extenders is a doable DIY task. Here are the necessary tools and materials required. First, turn off the power at the circuit breaker in the electrical panel. Then, .

In walls or ceilings of noncombustible material (such as drywall) outlet boxes must not be set back more than ¼ in. from the finished surface. In walls or ceilings of combustible material, outlet boxes must be flush with the . Box extenders are inexpensive, easy to install and — best of all — they bring your electrical installation up to code. Flush-mounted devices like receptacles and switches can only have a 1/4-inch gap between the front of . The National Electrical Code (NEC) contains minimum setback requirements for boxes installed in combustible, as well as noncombustible types of material. In walls or ceilings constructed of noncombustible material .

The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of electrical wiring systems. Here are some of the requirements that your business will need to follow. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Not all fixtures need to be attached to a wall stud or joist. .

The electrical cables that run through walls and in and out of electrical boxes must be both supported and installed with adequate lengths for connections in accordance with these code for proper installation and ease of use.In walls and ceilings constructed of wood or other combustible surface material, boxes, plaster rings, extension rings, or listed extenders shall be flush with the finished surface or project therefrom.Receptacles mounted in boxes that are set back from the finished surface as permitted in 314.20 shall be installed such that the mounting yoke or strap of the receptacle is held rigidly at the finished surface. Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold.

There are code requirements for the electrical box fit. NEC 314.20 allows a max of 1/8 gap at the box edge , I should have put this in the answer. Purchase some small washers and stack them in appropriate quantities behind the outlet, around the screws. Leave the outlet loose so that it fits the plate well. Installing box extenders is a doable DIY task. Here are the necessary tools and materials required. First, turn off the power at the circuit breaker in the electrical panel. Then, use a non-contact voltage tester (as detailed in the next section) to ensure all circuits in .

In walls or ceilings of noncombustible material (such as drywall) outlet boxes must not be set back more than ¼ in. from the finished surface. In walls or ceilings of combustible material, outlet boxes must be flush with the finished surface [Sec. 314.20].

Box extenders are inexpensive, easy to install and — best of all — they bring your electrical installation up to code. Flush-mounted devices like receptacles and switches can only have a 1/4-inch gap between the front of the electrical box and the finished wall. The National Electrical Code (NEC) contains minimum setback requirements for boxes installed in combustible, as well as noncombustible types of material. In walls or ceilings constructed of noncombustible material (concrete, tile, etc.), boxes must be installed so that the front edge will not be set back more than 1/4 inch from the finished . The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of electrical wiring systems. Here are some of the requirements that your business will need to follow.

The electrical cables that run through walls and in and out of electrical boxes must be both supported and installed with adequate lengths for connections in accordance with these code for proper installation and ease of use.In walls and ceilings constructed of wood or other combustible surface material, boxes, plaster rings, extension rings, or listed extenders shall be flush with the finished surface or project therefrom.Receptacles mounted in boxes that are set back from the finished surface as permitted in 314.20 shall be installed such that the mounting yoke or strap of the receptacle is held rigidly at the finished surface.

Installing electrical boxes the depth of drywall while studs and joists are exposed is a handy and simple solution for homeowners. To do this on your own, buy switch and receptacle boxes that meet local codes and are large enough for the wires they hold. There are code requirements for the electrical box fit. NEC 314.20 allows a max of 1/8 gap at the box edge , I should have put this in the answer. Purchase some small washers and stack them in appropriate quantities behind the outlet, around the screws. Leave the outlet loose so that it fits the plate well. Installing box extenders is a doable DIY task. Here are the necessary tools and materials required. First, turn off the power at the circuit breaker in the electrical panel. Then, use a non-contact voltage tester (as detailed in the next section) to ensure all circuits in .

In walls or ceilings of noncombustible material (such as drywall) outlet boxes must not be set back more than ¼ in. from the finished surface. In walls or ceilings of combustible material, outlet boxes must be flush with the finished surface [Sec. 314.20].

Box extenders are inexpensive, easy to install and — best of all — they bring your electrical installation up to code. Flush-mounted devices like receptacles and switches can only have a 1/4-inch gap between the front of the electrical box and the finished wall. The National Electrical Code (NEC) contains minimum setback requirements for boxes installed in combustible, as well as noncombustible types of material. In walls or ceilings constructed of noncombustible material (concrete, tile, etc.), boxes must be installed so that the front edge will not be set back more than 1/4 inch from the finished .

receptacle box wiring requirements

Keep items stored off the floor and secured in the 2000 Series 28-in. Wide Garage Storage Wall Cabinet. Mounts directly to wall studs or can be mounted to VERSATRACK™. Heavy-duty steel construction includes hardware and is ready to assemble.

electrical code for receptacle box installation on extension drywall|receptacle box wiring codes