electrical back to back boxes and putty pads Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation . You asked for information about the yellow box junction (YBJ) on the. A20 junction with Kidbrooke Park Road and Eltham Road. require. The YBJ at this location measures 41 m x 6.1 m. Department for Transport for its installation. YBJs are used to aid flow of traffic at main arterial junctions. We.A box junction is an area in the centre of a junction, usually at a busy crossroads or T-junction, where the road is marked with a yellow criss-crossed box. They are there as traffic .

0 · when are putty pads required

1 · quelfire putty pads

2 · lead pads for electrical boxes

3 · intumescent putty pads electrical boxes

4 · intumescent pads for electrical sockets

5 · firestop putty for electrical boxes

6 · acoustical pads for electrical boxes

7 · acoustical outlet backer putty pad

What is a Yellow Box Junction? A yellow box junction is a traffic control measure designed to prevent gridlock at junctions. They are there to help keep traffic flowing, although they are just treated as easy cash cows for local authorities.

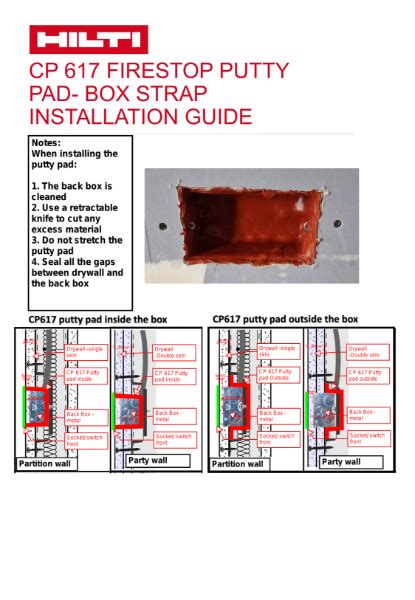

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials.

Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation .

when are putty pads required

quelfire putty pads

Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.Moldable putty pads are to be installed to completely cover the exterior surfaces of the outlet box (except for the side of the outlet box against the stud unless otherwise noted) including nailing .3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent .Install trusted fire seals around electrical boxes with putty pads. HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for .

Box inserts intumescent component will react to the heat of a fire to expand (“intumesce”) and form a fire-protective barrier. They are applied (self-adhered) to the external surfaces of .Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three .Moldable firestop putty to help protect electrical outlet boxes, junction boxes and metallic washer/dryer boxes Putty pads work by forming a fire resistant char when subject to fire conditions, stopping the spread of fire and smoke through socket boxes and plasterboard walls. In this blog post we'll take a closer look into what putty .

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials. Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation situations. If you’re looking to find out more about intumescent putty . Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.

Moldable putty pads are to be installed to completely cover the exterior surfaces of the outlet box (except for the side of the outlet box against the stud unless otherwise noted) including nailing tabs and to completely seal against the stud within the stud cavity.3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing .Install trusted fire seals around electrical boxes with putty pads. HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for protecting recessed electrical boxes – .

Box inserts intumescent component will react to the heat of a fire to expand (“intumesce”) and form a fire-protective barrier. They are applied (self-adhered) to the external surfaces of metallic and nonmetallic electrical boxes, applied to the back surface as well as the three sides of the box away from the wall stud.Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.Moldable firestop putty to help protect electrical outlet boxes, junction boxes and metallic washer/dryer boxes Putty pads work by forming a fire resistant char when subject to fire conditions, stopping the spread of fire and smoke through socket boxes and plasterboard walls. In this blog post we'll take a closer look into what putty pads are, when they .

lead pads for electrical boxes

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials. Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation situations. If you’re looking to find out more about intumescent putty . Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.Moldable putty pads are to be installed to completely cover the exterior surfaces of the outlet box (except for the side of the outlet box against the stud unless otherwise noted) including nailing tabs and to completely seal against the stud within the stud cavity.

3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing .Install trusted fire seals around electrical boxes with putty pads. HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for protecting recessed electrical boxes – .

Box inserts intumescent component will react to the heat of a fire to expand (“intumesce”) and form a fire-protective barrier. They are applied (self-adhered) to the external surfaces of metallic and nonmetallic electrical boxes, applied to the back surface as well as the three sides of the box away from the wall stud.

Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.Moldable firestop putty to help protect electrical outlet boxes, junction boxes and metallic washer/dryer boxes

intumescent putty pads electrical boxes

intumescent pads for electrical sockets

firestop putty for electrical boxes

acoustical pads for electrical boxes

$17.85

electrical back to back boxes and putty pads|acoustical outlet backer putty pad