how to make a folded sheet metal part solidworks To create a sheet metal part from the flattened state: Open a new part. Create a sketch as shown. You do not have to dimension the part. Create a Base-Flange by clicking Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The sheet metal features appear in the FeatureManager . Find sheet metal at Lowe's today. Shop metal sheets of steel, aluminum, tin, and a variety of materials. Shop in store or online at Lowes.com.

0 · solidworks sheet metal template

1 · solidworks sheet metal pdf

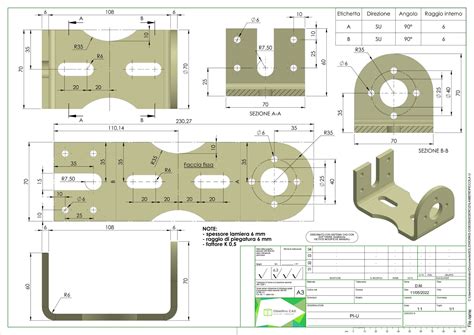

2 · solidworks sheet metal part drawing

3 · solidworks sheet metal drawing pdf

4 · solidworks sheet metal download

5 · solidworks sheet metal basics

6 · sheet metal drawing in solidworks

7 · sheet metal 3d sketch solidworks

LeMotech Junction Box, Electrical Box IP65 Water Resistant Dustproof ABS Plastic Project Enclosure for Electronics White, External Size 3.9 x 3.9 x 2.8 inch

solidworks sheet metal template

To create a sheet metal part from the flattened state: Open a new part. Create a sketch as shown. You do not have to dimension the part. Create a Base-Flange by clicking Base-Flange/Tab or Insert > Sheet Metal > Base Flange. The sheet metal features appear in the FeatureManager .

solidworks sheet metal pdf

Learn about the fold and unfold tools and how they can be used to help with cuts to our sheet metal part in SOLIDWORKS.Quick Tip presented by Tony Riggs of G. Check out hundreds of SolidWorks Tutorials at http://solidwize.com.This SolidWorks training video covers using the fold and unfold command in SolidWorks shee.

In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. You will learn below feature in SolidWorks: - convert part to sheet - fold and unfold #designsolidworks #solidworkstutorial #solidworkstutorialforbeginners Subscribe Watch Our Other Tutorials.To add a fold feature: In a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face . The fixed face can be a .

Fold sheet metal is used in the SolidWorks software to create a design that can be folded and then cut out. The process of creating a fold sheet metal design involves using the sketch .

Solidworks Sheet metal Fold and Unfold FeatureSolidworks Sheet metal tutorialIn this SolidWorks sheet metal tutorial we are going to learn how to make comple. How To Model Complex Sheet Metal Parts in SOLIDWORKS. A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat .

solidworks sheet metal part drawing

solidworks sheet metal drawing pdf

dometic brisk ii air distribution box filter

Most of the times a sheet metal product does not consist of just one folded sheet. Due to its size or complexity it has to be divided into multiple sheets, which are then bolted or welded. A common way of building such an .

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .

Mirror selected sheet metal features in the part; Create a second, mirrored sheet metal body in the part; Use the Insert > Mirror Part command to create a part that is an opposite-hand version of the original partNow create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .

Working with sheet metal jogs, sketched bends and cross breaks in Solidworks Solidworks Sheet metal Fold and Unfold FeatureSolidworks Sheet metal tutorialIn this SolidWorks sheet metal tutorial we are going to learn how to make comple.

Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model. I hope this article helped explain SOLIDWORKS sheet metal fold and unfold tools. Check out more tips and tricks listed below. Additionally, . This course teaches designers how to build standalone sheet metal parts and convert conventional parts to sheet metal in assembly context. Both online and in-person classes are available.In a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face. The fixed face can be a planar face or linear edge. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .

www.video-tutorials.netTo save 10% on all courses, please enter "youtube" at checkout. Get serious about your career and buy a course from us! Disc / downlo.Yes, correct. When you subtract a body from another body, the body you subtract is removed (That's just how SW is set up). You can use the move/copy feature with the copy option and no transforms to retain a second copy of the body for your drawing/modeling use.In this case, you create a sheet metal part, then insert bend lines on which to fold the part. To create a sheet metal part from the flattened state: . The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal. SOLIDWORKS includes sheet metal-specific .

By using the Base Flange/Tab, create a circle with a small gap in it. That gap is for the cut on the sheet to make it possible to roll in a cylinder form. After that you just add your thickness and bend radius. If you can use your flatten view then you know the sheet has a correct bend in it. Checkout our free inar for SolidWorks BeginnersIn a sheet metal part, click Fold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Fold. In the graphics area, select a face that does not move as a result of the feature for Fixed face. The fixed face can be a planar face or linear edge. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .One option would be instead of having the break be equal on the corner have your long edges go flush with the o.s. of the part. This would make it so when you look at the part from the top view instead of seeing 90 degrees in the corner that needs weld it would be flush.

Hi there, I was wondering if it was possible to put down a decal on a sheet metal part that has been folded out, and then unsupress the flat pattern to fold normally again, with the decal still intact. I am working with sheet metal for a cardboard project, and would love to make some renders with the decals on there.

Then, I create a sketch on a face and draw lines where it needs to bend, and then I press "sketched bend", but it's here where the problems happens: Some times it recognizes the line and bend it, sometimes does not recognize it at all; sometimes it bends the wrong part; sometimes it says it can't bend because the lines are connected ( mostly on .

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of . HI Guys im trying to get these two triangle parts to fold 90 degrees i cannot use a sketch bend as it wants to bend the entire edge Can you offer a solution?? Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. . How to make a sheet metal fold. AM By Adrian Miles 07 . ©2002-2024 Dassault Systemes .

I can make a five-sided open box of sheet metal, and obviously the 4 "walls" fold flat.so what to about adding the top? Make the top a separate part and start using assemblies? If so, how does the top (6th piece) get "welded" to the 4 walls below?I have a sheet metal part. I unfold it to create a cutout, then intend to fold it back. However, when I apply the fold, it folds the bend backwards (opposite how it was before the unfold). This has been a recurring problem, but it often goes away by showing and hiding the flat pattern repeatedly. In this particular case, that isn't working.Sheet Metal - Flat and Folded States. When designing Sheet Metal parts in SOLIDWORKS, configurations are used to represent the folded and flattened states. The flattened state configuration represents the manufacturing definition of the finished part. For most companies both configurations will represent the same part and part number, therefore .

Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . I normally would generate both a flat pattern as well as a folded views of the model, but I feel that it is way overkill to dimension every tiny little indent and notch and . Dear Viewers, In this video you will learn that how to make a Cut Across Bend for creating the slot in Sheet Metal with help of Fold, Unfold and Extruded-Cu.It is an innovative way to create sheet metal parts by using a combination of extrusion, lofting, and bending operations on the same part. . The benefits of using fold sheet metal in SolidWorks are: - It allows the user to create complex shapes with ease - It allows for more control over the design process, as well as provides a number of .

SolidWorks Sheet Metal Tutorial for Beginner - 2 | Closed Corner, Welded Corner, Break Corner, Corner Trim, Forming Tool. This tutorial shows how to create f.SolidWorks Tutorial for AdvancedIn this tutorial you can see few SolidWorks Tools use. You will learn below feature in SolidWorks:- convert part to sheet- .

solidworks sheet metal download

solidworks sheet metal basics

The Roper Whitney 5 Jr Light Duty Portable Punch Kit is a metal hole punch with punching power of up to 1.2 tons. It can save a lot of time over drilling sheet metal and is much more accurate. Easy to carry in the pocket, on a belt or in a tool box.

how to make a folded sheet metal part solidworks|solidworks sheet metal basics