what is the definition of cnc machine At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, .

Invest in home comfort or address heating and cooling needs without breaking your budget. 24/7 Emergency Services 831-392-0443. Clear sky . 11/07/2024. Facebook Twitter Instagram. Home; Wine Cooling Systems; About. Meet The Team; About Zenda Heating & Sheet Metal; Resources/Articles. Bryant Social Crew; Service Areas; Reviews; Image Gallery .

0 · what does cnc machine mean

1 · understanding cnc machines

2 · types of cnc machines

3 · how does a cnc machine work

4 · how cnc machine is controlled

5 · cnc machine used for

6 · best cnc machine for woodworking

7 · basic knowledge of cnc machine

Magnetic Storage for your MiniaturesStorage;https://amzn.to/42vSVu8Magnetic Sheets;https://amzn.to/3N0xXhDhttps://amzn.to/3oTAGRPMagnets 5x2mmhttps://amzn.to.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .

CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The . CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their . A CNC machine, also known as a Computer Numerical Control machine, is a manufacturing technology that uses a computer program to control the movement of specialized tools in subtractive manufacturing processes. CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

At its core, a CNC machine is a computer-controlled device that automates the operation of machine tools, such as mills, lathes, routers, and grinders. Unlike conventional manual machines, where operators physically manipulate tools, .

what does cnc machine mean

understanding cnc machines

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how . A machine tool equipped with a program control system is referred to as a Computer Numerical Control (CNC) machine. The control system processes relevant programs with control codes or other symbolic instructions, .Therefore, a CNC machine is a computer-controlled device that helps users cut, carve, and mill designs out of raw material. You can use CNC machines with an array of tools intended for different cutting abilities, and they’re compatible with . CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on .

Definition of CNC Machining. Now that we’ve covered the early history of lathes and milling machinery, let’s talk about the modern use of these tools. CNC machines have a program controlling the movement of tools that . CNC machine tools have higher precision than ordinary machine tools. During the machining process, the automatic machining mode of CNC machine tools can avoid errors caused by human factors, resulting in good .In CNC machining, the axes system is used to define the motion of the cutting tool relative to the workpiece. This system consists of several axes that control the movement of the CNC machine in different directions. . CNC machine tool is composed of a spindle, tool changer (tool holder and tool magazine manipulator), ball screw, and other .

What is CNC Milling Machine? CNC mill machine is an industrial tool that removes material from a stationary workpiece using rotating cutting tools to create precision parts. As a key piece of equipment in subtractive manufacturing, it can be operated . A more complete definition. A CNC machine at the most basic level is nothing more than a computer controlled machine. CNC is an acronym for Computer Numerical Control. You can read more about Numerical Control here. Typically when people talk about CNC machines they are referring to machines used in the industrial manufacturing world.

types of cnc machines

In CNC machine shops, meticulous programs are designed or prepared beforehand and then fed into the CNC machine. The CNC machine, in turn, adheres to the instructions outlined in the program, expertly controlling the motion and speed of the machine tools to achieve exceptional levels of precision and productivity. Fig 1: CNC machine What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and .

CNC machine tools can be classified based on their motion tracks into three categories: point-controlled, straight-line controlled, and contour controlled. (1) Point control CNC machine tool. Positioning control, also known as Point-to-Point Control, is a technique used to precisely position moving parts from one position to another. cnc machine in hindi, working of cnc machine, what is cnc machine, cnc machine components👉MTS के Pdf Notes के लिए इस वीडियो को देखें-Click here .As technology continues to evolve, so does manufacturing, and Computer Numerical Control machines are one of the highlights of this field.Known for their high precision, efficiency, and versatility, CNC machines have become a mainstay of modern manufacturing.In this article, we will take an in-depth look at the definition, working principles, types, application areas and .The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls. Early efforts involved analog computers and punch-card systems to control machine movements.

box of 9mm full metal jacket

The Basics of CNC Machining Definition and History. CNC machining solutions are a subtractive manufacturing process in which a computer program guides different tools to create a product. The tools include drills, lathes, and mills that cut away at a workpiece to achieve desired specifications. CNC Bending Machine for Angle Bending and Imprint Bending. CNC bending machines offer specialized solutions for angle bending and imprint bending, catering to diverse applications in various industries. These machines leverage CNC technology to deliver precise and consistent bends, ensuring high angle accuracy and complex bend formations.What is the definition of centre height in CNC lathe machines? Centre height is a crucial parameter in CNC lathe machines as it directly influences the tool performance and machining accuracy. In simple terms, it refers to the distance . Reasonably determine the functions of CNC machine tools. When selecting the features of CNC machine tools, it’s important not to prioritize a large number of functions or excessive specifications. Having too many coordinate .

CNC programming entails creating precise instructions for CNC machines to control tool movements for tasks like cutting, drilling, milling, or shaping materials. . You could also call them non-geometric codes because .Definition of CNC Machine. Let me first introduce you about what is CNC machine, so CNC stands for Computer Numerical Control. When computers are used to control a Numerical Control (NC) machine tool than the machine is called CNC machine. In other words, . Definition. CNC routers are machines used to cut many types of materials, such as wood, plastic, aluminum, and high-density foam. . In most cases, CNC machines can cut along three directions known as the X, Y, and Z axes. The X-axis is the front to back direction, which is usually the longest. The Y-axis is the left and right direction and .

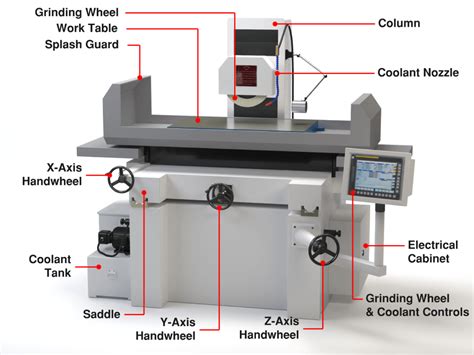

Elements of CNC Machine. The CNC machine comes with the following elements: Program. Tape Reader. Mini-computer. Servo system. CNC machine tool. Program. The keyboard is used to enter the program into the computer. The program is the code used to guide and control the machine's functions. The common CNC codes include: G code, N code, F code . The Machine Definition is a Graphic User Interface that was created by CNC Software to give Mastercam some "intelligence" about the type of machine you are using. There is a distinction that I'm making here between the "Mastercam" interface (where you create Tool Paths) and the Post Processor, that formats your Tool Paths into NC code.

CNC welding integrates the conventional welding procedure with a CNC machine movement. All types of welding machines such as TIG, MIG, and plasma arc welding can work well with CNC machine tools. CNC welding is used in high-speed metalworking areas like the automotive sector. A CNC machine is a highly automated piece of equipment that can turn digital blueprints and designs into manufactured products with precision. A computer tells the CNC machines what to do, which then guides the cutting tools and other instruments to shape, cut, and produce parts from various materials ranging from metal to plastics. CNC drilling machines come in various configurations, each designed to meet specific needs and applications in the manufacturing industry. Understanding the technical aspects, benefits, and applications of each type can help you select the most appropriate machine for your manufacturing requirements. CNC machines are susceptible to certain problems like every other machinery. Some common CNC machine problems are: Overheating: CNC machines have a lot of moving parts that can overheat due to the high heat generated in the machining operation. Tooling: CNC machines require a proper understanding of tooling to achieve the desired result. Wrong .

To understand how does 5-axis CNC machining work, first you should know about the machine. 5 axis CNC machine refers to the computer controlled machines has the capacity to move a tool or a part in five different axes simultaneously, typically is adding two rotation axes to the three linear axes (X, Y and Z). 5-axis CNC machines are the most advanced type of CNC machine, adding two rotational axes, typically referred to as the B axis and C axis, to the three axes of the 3-axis machine. This allows for even greater precision and complexity in the production of parts and components. 5-axis machines are commonly used in the aerospace and defense .

how does a cnc machine work

$80.78

what is the definition of cnc machine|how cnc machine is controlled