copper brass sheet metal spinning parts for sale Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled . Silver is perhaps the most versatile metallic color to decorate your home with. Find out the best colors that go with silver for your next home decor project.

0 · metal spinning techniques

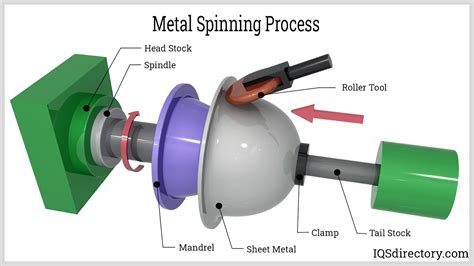

1 · metal spinning process

2 · metal spinning machine

3 · metal spinning lathes

4 · metal spinning crafts

5 · metal craft spinning machine

6 · history of metal spinning

7 · automatic metal spinning machine

Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines.

Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Specifications: Materials: steel, galvanized steel, stainless steel, .Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a .Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS Compliant Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled .

We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls .

Daisy Metal Spinning uses a variety of materials for metal spinning such as cold rolled steel, aluminum, stainless steel, brass, copper and exotic metals such as titanium, inconel, and hastealloy. Daisy Metal Spinning specializes in the .Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Specifications: Materials: steel, galvanized steel, stainless steel, and aluminum. Special or decorative metals: copper, brass and bronze

Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a CNC lathe, and is a cost-effective alternative to low volume or short run metal stamping.Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS CompliantMetal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled steel. Traditionally, metal spinning has been associated primarily with low volume production, chiefly due to the requirement for highly skilled human operators in a trade with a rather steep learning curve.

We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls to fulfill custom orders that call for strong, sturdy metal construction.Daisy Metal Spinning uses a variety of materials for metal spinning such as cold rolled steel, aluminum, stainless steel, brass, copper and exotic metals such as titanium, inconel, and hastealloy. Daisy Metal Spinning specializes in the forming of all materials.

Key Specifications/ Special Features:. Profession: We're the custom sheet metal and CNC machining manufacturer for over 12 years. Production: Based on customers' drawings, and also can make special design for customers. Materials: Aluminum, Stainless steel, Tool steel, Brass, Copper, Bronze and other material can be used. Dimensions: It can be customized.From parts to finished goods, including in-house: Spinning - Machining - Stamping - Welding - CNC Plasma Cutting - Tool & Die - Powder Coating - Fabrication while stocking sheet steel, stainless, aluminum, copper, brass in many alloys and thicknesses for rapid turn-around.

Copper Metal Spinning. The copper parts produced by P&J Metal Craft are used for lighting, roofing and decorative purposes since copper are a popular alloy that is known for its heat resistant abilities.

Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Specifications: Materials: steel, galvanized steel, stainless steel, and aluminum. Special or decorative metals: copper, brass and bronzeWenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a CNC lathe, and is a cost-effective alternative to low volume or short run metal stamping.Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS Compliant

metal spinning techniques

Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled steel. Traditionally, metal spinning has been associated primarily with low volume production, chiefly due to the requirement for highly skilled human operators in a trade with a rather steep learning curve.

We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls to fulfill custom orders that call for strong, sturdy metal construction.Daisy Metal Spinning uses a variety of materials for metal spinning such as cold rolled steel, aluminum, stainless steel, brass, copper and exotic metals such as titanium, inconel, and hastealloy. Daisy Metal Spinning specializes in the forming of all materials.

Key Specifications/ Special Features:. Profession: We're the custom sheet metal and CNC machining manufacturer for over 12 years. Production: Based on customers' drawings, and also can make special design for customers. Materials: Aluminum, Stainless steel, Tool steel, Brass, Copper, Bronze and other material can be used. Dimensions: It can be customized.

From parts to finished goods, including in-house: Spinning - Machining - Stamping - Welding - CNC Plasma Cutting - Tool & Die - Powder Coating - Fabrication while stocking sheet steel, stainless, aluminum, copper, brass in many alloys and thicknesses for rapid turn-around.

metal spinning process

Instead, the star is the washer for an iron rod placed through a sagging or compromised wall to preserve its structural integrity and prevent it from buckling further.

copper brass sheet metal spinning parts for sale|metal spinning techniques