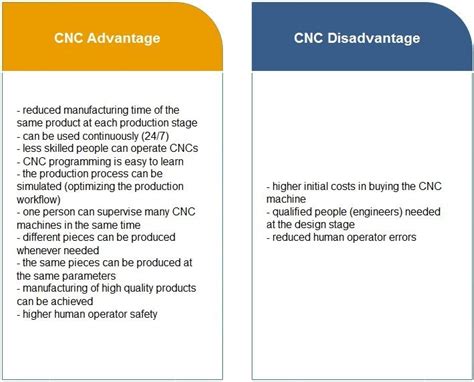

advantages of using cnc machines CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that . Closed junction box for the connection of cables in indoor and protected outdoor areas. Rectangular design without entries. Suitable for wall and ceiling mounting, on mounting panels .

0 · disadvantages of cnc milling

1 · disadvantages of cnc machines

2 · cnc milling advantages and disadvantages

3 · cnc machining advantages and disadvantages

4 · cnc machine pros and cons

5 · advantages of cnc milling machine

6 · advantages and disadvantages of cnc

7 · advantages and disadvantages milling process

Tri-metal Fabricators Ltd is a leading company activating in Steel-structural (manufacturers) industry, located in Delta, BC. The driving force behind our reputation is our employees, who have invested a lot of energy in the development of our business here in Delta.

What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and . As with any manufacturing process that has lasted for decades, CNC machining offers numerous advantages over other part creation methods. Using computer control allows you to get consistently precise and accurate .CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.

What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process . Here are 14 advantages of CNC machines offer. 1. High Precision and Improved Accuracy. One of the most significant benefits of using CNC machining compared with manual operations is precision. It’s possible to .

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the . CNC machines deliver a production capacity ideal for creating large quantities of items which require accurate, consistent, complex cuts. The advantages of this method of manufacturing has led many companies to . What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.

disadvantages of cnc milling

As with any manufacturing process that has lasted for decades, CNC machining offers numerous advantages over other part creation methods. Using computer control allows you to get consistently precise and accurate results with various materials.CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that enhance product precision, improve efficiency, boost profit margins, and increase overall market competitiveness. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting. What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process Increases safety during machining Helps complete tasks faster and in details Reduces changeover time Boosts production volume Here are 14 advantages of CNC machines offer. 1. High Precision and Improved Accuracy. One of the most significant benefits of using CNC machining compared with manual operations is precision. It’s possible to create parts that meet precise specifications without the need for constant attention from a skilled operator. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.

CNC machines deliver a production capacity ideal for creating large quantities of items which require accurate, consistent, complex cuts. The advantages of this method of manufacturing has led many companies to completely replace engineer-operated equipment with the efficient, tireless precision of automated machines.

What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process. As with any manufacturing process that has lasted for decades, CNC machining offers numerous advantages over other part creation methods. Using computer control allows you to get consistently precise and accurate results with various materials.

cnc milling machine operation

CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that enhance product precision, improve efficiency, boost profit margins, and increase overall market competitiveness. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.1) Accuracy: The accuracy of CNC machines can be up to 10 times better than manual cutting, especially the 5-axis cnc machine is the option for high-end precision machining projects. 2) Speed: It is much faster than manual cutting.

cnc milling machine tutorial

What Are the Advantages of CNC Machining? CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process Increases safety during machining Helps complete tasks faster and in details Reduces changeover time Boosts production volume Here are 14 advantages of CNC machines offer. 1. High Precision and Improved Accuracy. One of the most significant benefits of using CNC machining compared with manual operations is precision. It’s possible to create parts that meet precise specifications without the need for constant attention from a skilled operator. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.

disadvantages of cnc machines

cnc milling advantages and disadvantages

We are the oldest heating/cooling contractor in Geneva. Service and installation of heating and air conditioning equipment. Honeywell Electronic Air Cleaners. From a kitchen hood to an industrial ventilation system.

advantages of using cnc machines|disadvantages of cnc machines