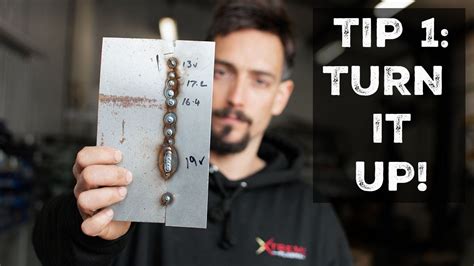

welding sheet metal body panels Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Installing a metal door frame offers security, soundproofing, durability, and fire and pest resistance that cannot be matched by timber. If you’re worried about the big bad wolf or just want the best door frame for your home, office or commercial building, then a metal door frame is the ideal choice.

0 · welding patch panels on truck

1 · welding in replacement body panels

2 · welding body panels with mig

3 · welding automotive body panels

4 · welding auto body patch panels

5 · mig welding automotive body panels

6 · mig welder for body panels

7 · best welding for auto body

Choose from our selection of recessed handles, including over 200 products in a wide range of styles and sizes. In stock and ready to ship.

Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. See more

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.The excessive heat can easily blow holes through sheet metal or lead to warping. There is also more spatter and slag formation using FCAW which can cover small holes on the welded metal creating further issues. . If you ask any welder out . Aluminum welding will also require 100% argon gas instead of the usual 75%/25% argon/CO2 mix. Speed – MIG welding is generally faster than TIG welding, especially for those who may not weld very often. For thin metal like body panels, MIG welding requires stitching together a series of spot welds to create a complete seam. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

The Hot Rod Hippie discusses Butt Welding vs Lap Welding Sheet Metal Panels on your hot rod or custom vehicle project. Which should you be using? . Chassis / Body Swaps ~ Where to Start; Roadkillers: Featured Vehicles; Photos, . In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

Auto Body. Rotisserie & Body Carts; Panel Replacement; Sanding Blocks & Boards; Dent Repair; . 1/8" Holders grip sheet metal parts before final welding.hands-free . 1/8" Holders grip sheet metal parts . Eastwood Cleco Sheet Metal Fasteners Cleco Pliers Panel Holding System 10 1/8 in. Blind Holders & 2 Side Holders For Edge Work . If you can weld in a patch panel with FCAW, you are good - and patient. FC runs too hot to be used easily for body panels. You'll burn through quickly, and that will get old quick. If you are able to weld in small enough spots to keep from burning through, the chipping of slag between welds will get old even quicker. Dave

I've done quite a bit of body repair honestly all processes make to much heat and you get warpage even spot welds if done in a row will warp gas brazing seems way too hot and I've found mig welding the whole seem is a nightmare to grind cause the weld will be much harder than the sheet metal I've had some success with Tig no filler but its only ideal for all new .

Importance of welding car sheet metal. Body panels come loose, rust and eventually need to be replaced. This can be very expensive and inconvenient. It can also be dangerous if the panel gets loose and hits someone. Welding sheet metal is a great way to repair body panels. It’s usually cheaper than replacing the entire part. However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels. The panels’ aluminum’s chemical properties also require high voltage and wire feed speed settings to match the appropriate mode of metal . Butt Welding Clamp Sturdy Durable Butterfly-shaped Clip Sheet Alignment Positioner Straight/Curved Panels for Automobile Car Truck Door Skins Feature: Material: The welding clamps are made of high quality tool steel. They are rustproof, heat resistant and durable.

I welded up some sheet metal with my new to me MM250 with the standard .035 wire. The tack, tack, tack method worked great for me and can be fast once you get into it. This was my second actual MIG weld I done going from the sheet metal to 1/4" box tube. To align and clamp sheet metal panels for precise spot welding,butt welding,edge-to-edge welding and tacking in place ; For precise spot welding, positioning, butt welding and edge-to-edge welding, fully align and clamp the metal plates. . 8PCS Butt Welding Clamps Weld Sheet Metal Clamps for Auto Car Door Body Panel to Welding. 3.8 out of 5 . Butt joint aare the preferred method for sheet metal panels when welding. Brazing works well and makes a strong connection on lap joints but body work doesn't do well on top of lap joints -brazed or welded. Brazing is good on fillet welds too and comes in real handy on special situations. I would reccomend practicing your welding first on either scrap sheet metal or new sheet metal (I think I paid about for a 4x8 foot sheet of 16 or 18 gauge steel a few years ago). My build thread, as well as other peoples' threads, offer lots of photos and commentary about the sheetmetal repair process.

8pcs Butt Welding Clamps Weld Sheet Metal Auto Body Panel Clamps Butterfly-shaped Clip Sheet Alignment Positioner for Car Truck Door Skin Panel Fender . Visit the Walfront Store. .36 $ 18. 36. Save 5% at checkout . GET THE AIR FLANGE TOOL HERE http://www.amazon.com/gp/product/B007QV7WW0/ref=as_li_tl?ie=UTF8&camp=1789&creative=390957&creativeASIN=B007QV7WW0&linkCode=as2&. until you get the hang of welding try putting a 1" metal strip under your weld. Plug weld to each panel [which means drill some 5/16 holes in the top panels and weld though to the strip under them]. Leave about a 1/4 gap between your two panel you plan to butt weld together.This way you you have metal under your weld so you don't blow holes and . Get the 2 pieces as close together as possible with clamps, vice grips, sheet metal screws or even dent it if you have to. Cut the mig wire flush with the nozzle every time before you start, I like to start the weld on the frame rail in the centre .

20 Gauge Aluminized Steel Panels for body panel repair.corrosion-resistant, and easy to weld. If you're making your own patch panels, or you need extra panels for use with our 13376 Patch Panel Kit, here's the same type of aluminized steel used by exhaust manufacturers for corrosion protection; also allows easy forming and welding. One 12" x . Acrux7 16 PCS Butt Welding Clamps, Small Sheet Metal Clamp, Carbon Steel Panel Clamps for Auto Body Edge to Edge Welding (1x2.3 Inch) 4.6 out of 5 stars 11 1 offer from 69 $ 17 69

Lap welds are for quicky body shop jobs, overlapping metal is just an invitation for rust. However if two pieces of metal must be overlapped both sides of the seam should be protected from the elements either by paint, seam sealer or undercoating. . Drill out the top panel and plug weld the two panels together. After that you can weld the . Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an. Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how v.

Here's a few tips on repairing rust holes in car body panels.Wanna buy me a beer? https://www.paypal.com/donate/?hosted_button_id=WZS79GVX5VBJ2In this video .

welding patch panels on truck

Have an air wond on hand and cool the weld with air after the three spot welds. Below is a video how to weld sheet metal the right way. Use this same technique for the edge. The welding is near the end of the video. He as has a good video available on ebay called panel perfect showing exactly what your trying to do. Well worth the .

lr3 land rover 2008 fuse diagram central junction box

The likely scenario is that the single white wire is the switched hot and the bundled white wires are the neutral. You need to confirm this. With all wire bundles clear of each other .

welding sheet metal body panels|welding automotive body panels