sub panel junction box A subpanel serves as a satellite breaker box and offers a convenient way to control circuits in a remote location, such as a garage or . Typical metals used for roofing include steel, aluminum, copper, and zinc. The cost of metal roofing also varies on the specific material you use. Steel is the most popular and typically least expensive metal roofing option. It’s known for its strength and durability, often lasting for 30–50 years or more.

0 · when to use junction box

1 · waterproof electrical distribution panel box

2 · junction box wall mounted

3 · junction box outlet

4 · junction box catalogue pdf

5 · junction box 200x150x100

6 · heavy duty junction box

7 · electrical panel junction box

M-codes are the universal language in computer numerical control (CNC) machining. M-codes, “miscellaneous codes,” are fundamental in teaching CNC programs. .

As far the actual junction box question: You can certainly have junction boxes in between sections of conduit, and switch between wire types.You don't need to do that -- you can get a flush-mount box by itself that fits your .You can get extension boxes (that size box with an open back designed to stack on . A subpanel serves as a satellite breaker box and offers a convenient way to control circuits in a remote location, such as a garage or .

How to Plan for a Sub Panel; Planning for an Electric Sub Panel: Identifying Panel Circuits and Connected Loads. Sub Panels are installed and used for several reasons including expanding the circuit breaker capacity of the main electrical . You don't need to do that -- you can get a flush-mount box by itself that fits your needs. What you're looking for isn't a "breaker panel", really. It's . The heart of a home's electrical system is the main circuit breaker box, also known as the main service panel. This is where the power feed from the utility company first enters the home from the meter and the point at which all . Can I replace this old panel/junction box with a new sub panel and meet 2020 code compliance? My foremost concern is whether this is a modification to the branch circuit wiring for the eight circuits mentioned above .

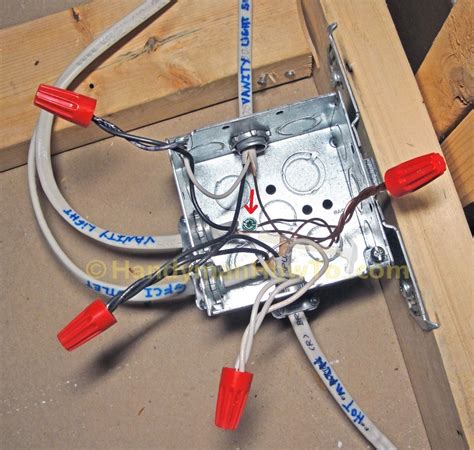

I ran EMT metal conduit from the panel to new junction box locations, then ran the individual circuits in THHN wires -- marked so I knew which neutral was paired to which hot(s). This meant all cables coming in .Devices and Junction Boxes Select the right box for your application 120/240 Volt Sub-Panel Circuit Requirements 4-Wire System consisting of: 2-Insulated Power Conductors (Black & Red) 1-Insulated Neutral Conductor (White) . Is the Wire Size to my Sub Panel Too Small? A single panel or group of panel units designed for assembly in the form of a single panel, including buses and automatic overcurrent devices, and equipped with or without switches for the control of light, heat, or power circuits; designed to be placed in a cabinet or cutout box placed in or against a wall, partition, or other support;Sub-panel 60-Amp Breaker Boxes . 2 results . Sort By. Sort By. Compare. Siemens EQ 60-Amp 2-Spaces 4-Circuit Indoor Main Lug Load Center .

I'd use a flush mount NEMA 1 pull box and mechanical setscrew/splice connectors. While an ordinary junction box is simply too small for splicing 4AWG conductors, larger boxes are available. These are called pull boxes or NEMA enclosures, and in particular, you need a flush mount (into the ceiling), NEMA 1 (indoor) box. Size-wise, you are looking at a minimum dimension of 6" .Amazon.com: electrical sub panel box. . Maxxima 1 Gang 18 cu. in. PVC New Construction Electrical Switch and Outlet Junction Box, New Work Non-Metallic Electrical J-Box w/Nail, ETL Listed, 2 Hour Fire Rating, Gray, 10-Pack. 5.0 out of 5 . Electrical - AC & DC - how to turn panel into junction box. - The inspector told me I had to turn our old house panel (now acting as a sub panel), into a junction box because of the metal bar from the airconditioning didn't leave it 36 inches of cleareance look picture. So remove the air conditioner metal or make a

Sub Panel Box: Ensure you have the correct sub panel box for your specific needs. This will typically include the main lugs, a neutral bar, and a ground bar. Circuit Breakers: You will need to purchase the appropriate circuit breakers to fit your sub panel box and accommodate the electrical load requirements.

when to use junction box

Junction box connections for sub-panel transfer switch (Ontario, Canada) I would like to set-up a transfer switch, for my home, connected to a portable inverter generator. Other than an interlock implementation, in my province (Ontario), there seem to be two approved options: Generlink or Reliance Controls. Moving my sub-panel (approximately 20' from the existing panel). My question is. for the conductors that cannot reach the new sub-panel, can I use the old (dead)sub-panel as a j-box to run the circuits to the new panel? I think I'll be good on the box fill because about half 1/3 of the conductors will reach the new panel.The panel is on the exterior wall of my attached garage, inside of which I want to install a sub-panel, and a 240v outlet for my welder. If you can visualize, this box is where I will begin my two conduit runs: one for the sub-panel, and one for the outlet. 3/4" conduit with 4 x 6awg conductors, and 1/2" conduit with 3 x 8awg conductors.

If you want to keep the existing panel, as a panel, then Harper's advice of leaving the panel and using it as a sub-panel is a good idea. If you don't need the panel and just want to extend the circuits to the new location, you could use the old panel AS the junction box and have a sheet metal cover fabricated for it.Shop for sub panel breaker box on Amazon.com and explore our fast shipping options. Browse now and take advantage of our fantastic deals! . 4.9 x 2.2 x 3.5in IP66 Waterproof Transparent Cover 2 DIN Rail Outdoor Distribution Junction Box for Indoor Outdoor Wall Circuit Breaker(2 Way) 4.4 out of 5 stars 159. 100+ bought in past month. Hey guys. I'm doing a relocation of a 100Amp sub-panel from customers basement to 1st floor. The house is in a flood plane and floods frequently, submerging the entire panel under water. Questions being. Can I . I could then simply disconnect the circuit wires I want to move from their breakers in the main panel and run them into the junction box through the nipple. Within the junction box, I can wire nut them to wires that will run to the sub panel. I can also route my feed wires from the main panel, through the junction box and conduit to the sub panel.

The ground path back to the main panel is receptacle > second junction box in Shed 1 > 20 amp breaker. The neutral path back is the same. The hot wire path to first receptacle is 20 amp breaker > 10-2 wiring to junction box where 10-2 wiring is split > single pole termination point > 12-2 hot wiring to first receptacle.Determining junction box vs. sub-panel? I was initially planning to run a new 15 amp circuit to the garage with a 12/2 NM-B cable about 25 feet. I intended to wire into a junction box. From there, I'd run PVC conduit with THHN wires throughout the garage to numerous 15 amp receptacles. At the moment, 15 amps will be more than adequate for my needs. Kyle, somebody in the past installed the sub-panel and used the liquidtight conduits to avoid the vertical stud between the panels. The larger conduit is the feeder for the sub-panel. The junction boxes 'intercepts' some of the NM circuits that used to go into the main panel and 'divert' them to the sub-panel. Most of the circuits in the old panel will be run using #14 or #12 wire, with a few using larger size wire for major appliances. Running the existing panel as a sub panel would require moving some of those loads and running a new feeder for the sub-panel. Much easier to just use the old panel as a junction box and be done with it.

Install a junction box to transition from 10 AWG to 8 AWG for the breaker. or. Attach the whip to the panel directly with an appropriate clamp and transition from 10 AWG to 8 AWG inside the panel. 10 AWG to 8 AWG does not require Polaris or other expensive connectors. According to the Ideal catalog, you can use: 342 Gray; 454 Blue; BT2 RedPanel for Junction Box, fits 16x14 Box, White, Mild Steel Catalog#: A16P14. Use these panels in Junction Boxes. Available in various materials to meet various application requirements. Stainless steel and aluminum panels are protected on one side with a plastic film. Read more . In this video, I show you how to install and wire an electrical sub panel. You see the complete process, from start to finish. 00:00 Intro03:02 Purchasing .

waterproof electrical distribution panel box

The junction box and terminal block is to allow the use of multiple Tesla wall connectors in the future using the same 100A branch circuit from the sub panel. That's allowable because of the networking that allows the master wall connector to limit to total current between all wall connectors to 80A.Sub-panel Breaker Boxes & Parts . 41 results . Sort By. Sort By. Compare. Square D Homeline 125-Amp 12-Spaces 24-Circuit Indoor Convertible Main Lug Plug-on Neutral Load Center (Value Pack) . Basic info: Garage is approx 90 feet from house. Exit point of house to main panel is approx 25’ run. Main panel is 200 amp with plenty of space remaining. My plan is bury 2” conduit 18” to detached garage. The junction box will be inside of main house to underground conduit. My questions for starters :

junction box wall mounted

junction box outlet

Sheet metal shearing is a fundamental fabrication process that involves slicing through metal sheets to separate them into different sizes and shapes. This technique uses a pair of sharp blades, one typically fixed and the other moving vertically, to exert a shear force across the metal sheet.

sub panel junction box|junction box catalogue pdf