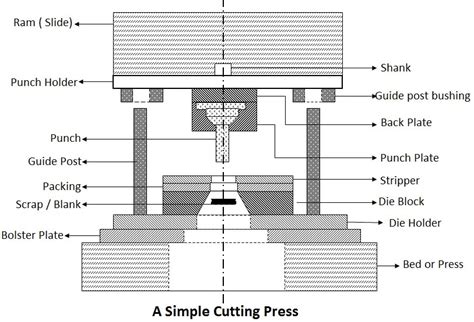

sheet metal stamping guidelines The Anatomy of a Hole. Normal metal stamping processes involve driving a sharpened tool steel punch through the sheet or strip material and into a die cavity where the slug or scrap is . Metallic paint is a faux finish that, when painted on walls, doors or ceilings, brings an added sparkle to your home. It takes a little more elbow grease to apply than a standard paint job, and you need to know some special techniques to get the best look.

0 · stamping design guidelines pdf

1 · sheet metal stamping process pdf

2 · sheet metal pattern layout methods

3 · sheet metal fabrication handbook pdf

4 · sheet metal design guidelines pdf

5 · sheet metal design calculations pdf

6 · sheet metal bending guide pdf

7 · metal stamping process flow chart

The Abtech ZAG range of aluminium enclosures and junction boxes have many features for use in a wide range of electrical applications - including industrial and hazardous area junction boxes and OEM applications .

This comprehensive guide is designed to equip engineers and designers with the knowledge and insights to optimize their sheet metal stamping designs. From material .The Anatomy of a Hole. Normal metal stamping processes involve driving a sharpened tool steel punch through the sheet or strip material and into a die cavity where the slug or scrap is .

Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers. Parts can be flat and simple or complex profiles. . Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in various industries, including automotive, .

Master sheet metal stamping design with this comprehensive guide. Learn essential tips on material selection, bend design, and tooling for optimal results.Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and . An overview of the top considerations to make and standards to follow when designing parts for the metal stamping manufacturing process. Metal stamping is a manufacturing process in which coils or flat sheets of material .Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient .

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also .

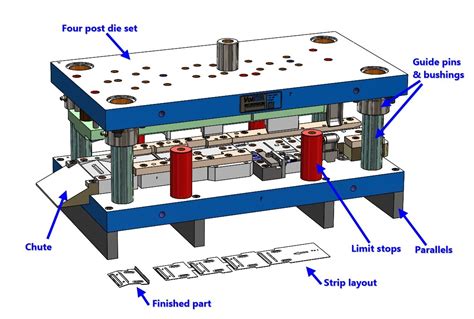

The basics of metal stampings. Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers. Parts can be flat and simple or complex profiles. Stampings are produced using a variety of punch presses that brings to bear ten to hundreds-of-tons of stamping pressure

The forming process, on the other hand, can involve metal stamping, progressive die stamping, deep draw stamping, or fourslide stamping. The Benefits of Employing Sheet Metal Components. . the process involved .The document provides guidelines for sheet metal stamping design. It begins with an overview of the sheet metal stamping process, including its definition, characteristics, applications, advantages and disadvantages. It then discusses different classifications of stamping processes based on deformation properties and basic deformation methods. Finally, it covers .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed into the final part using press brakes and die tools. Parts can be finished with inserts, welding, surface Sheet metal stamping is a versatile and efficient manufacturing process capable of producing a wide array of complex parts for various industries. . By following these design guidelines and partnering with a knowledgeable metal stamping provider, you can unlock the full potential of sheet metal stamping for your next project. .

Specific tolerance guidelines integral to sheet metal fabrication are detailed in the table below. Each entry details the acceptable variance for various methods of fabrication and assembly. With values expressed in both millimeters and inches, the table serves as a reference, covering aspects from forming and bending to the relationships .guidelines herein are for normal stamping operations only, with no reference to roll forming or warm . or for mass reduction through a reduction in sheet metal thickness, or gauge. An increase in strength generally leads to reduced ductility or formability. Care must be taken in designing parts, tooling, and fabrication processes to obtain .The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. In this guide, we will explore the 7 pivotal steps in sheet metal stamping. Each step is a piece of a larger puzzle that, when completed, represents . Sheet metal stamping is a versatile and efficient manufacturing process capable of producing a wide array of complex parts for various industries. However, designing parts for sheet metal stamping requires a specialized understanding of engineering principles and manufacturing limitations.. This comprehensive guide is designed to equip engineers and designers with the .

Sheet Metal Stamping. It is a high-volume manufacturing process that uses dies to transform flat metal sheets into particular shapes. The process starts with inserting the sheet into a stamping press where a tool and die surface apply pressure to form, cut or punch the metal into the desired form. . Different international guidelines . Editor's Note: This series presents an overview of metal stamping. Part I focuses on the various careers in the metal stamping industry. Part II discusses stamping materials and equipment. Part III focuses on dies and cutting and Part IV offers more detail about cutting processes. Part V, the final installment, investigates forming methods.To ensure the success of your custom sheet metal stamping project, it's essential to adhere to specific design guidelines that optimize the process and end-product quality. HSJ, as a professional sheet metal stamping expert, has rich experience in custom sheet .

Metal stamping is a transformative manufacturing process that manipulates flat metal sheets into specific shapes. Welcome to the realm of metal stamping design, an intricate world that intertwines creativity, precision, and engineering. Metal stamping is a cornerstone of multiple industries, ranging from automotive to aerospace, from . Sheet metal stamping is a metalworking process of shaping metals into desired forms using a punch, blanking die, bending die, and coining die. This technique is commonly used in automotive, medical, and construction industries because it offers a chance to produce many parts at a cheap price. . Sheet Metal Design Guidelines ensure efficient . For instance, if you’re working with a 2mm thick sheet, your hole diameter should be at least 2mm. . In conclusion, whether you are an experienced engineer or new to metal stamping, keeping these guidelines at .

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . but this article will focus on the most common press break and .DFMPro for Sheet Metal Design Guidelines. DFMPro provides pre-configured design guidelines DFM rules for design which helps to develop better quality parts at reduced cost. Some of the common sheet metal design guidelines included are minimum distance between holes, cutouts, slots, distance between holes, cutouts, slots to part edge and bends, multiple bends in same .

stamping design guidelines pdf

sheet metal stamping process pdf

Metal Stamping: Sheet Metal Design Guidelines. During the metal stamping design process, it’s important to consider the following guidelines: Holes When using metal stamping to create holes, the hole diameter should always be equal to or more than 1.2 times the thickness of the material. If the metal has high tensile strength, such as .

Metal stamping or metal pressing is a process that consists of a series of processes actually, including bending, punching, and blanking with tools and dies, coining, flanging, etc. The process gives the metal sheet the desired shape according to your design. It is one of the most used metal forming processes. The guidelines available through WorldAutoSteel enable those who are making automotive structures to master the fundamentals and get up to speed on specific application knowledge. . Steel Lubricants – 10/12/2012 – Report that specifies the acceptable performance requirements for automotive sheet metal lubricants. Stamping and Formability .

sheet metal pattern layout methods

Sheet metal stamping process flow diagram, metal stamping is a cold-forming process, which uses a special tooling system and force to transform sheet metal into useful parts. . Design the sheet metal part you wish to make – of course, you must follow the recommended sheet metal stamping design guidelines; Choose a suitable material – the .

sheet metal fabrication handbook pdf

Editor's Note: This series presents an overview of metal stamping. Part I of this series focused on the various careers in the metal stamping industry. Part II discussed stamping materials and equipment; Part III focuses on dies and cutting and Part IV offers more detail about cutting processes. The final installment, Part V, investigates forming methods.• Secondary operations may be required to trim displaced metal. • Design for minimal material displacement. [email protected] | 607.227.7070 | www.incodema.com • Process by which metal currency is minted. • Surface material is pressed. • Requires moderately priced tooling.Sheet metal stamping/drawing – car industry •90million cars and commercial vehicles produced worldwide in 2014 . Stamping Auto body panels •3 to 5 dies each • Prototype dies ~ ,000 • Production dies ~ Introduction to the sheet metal/ metal stamping industry BWC identified sheet metal and metal stamping employers among the top 10 workers’ compen-sation classifications with the highest fre-quency of claims and highest claims costs in Ohio. According to the National Council on Compensa-tion Insurance’s (NCCI’s) manual classifications,.75-1 • Forming dies • Trimming station .

sheet metal design guidelines pdf

Yukon Tool® offers a wide range of storage solutions to keep your workspace organized and tools secure, including sturdy tool cabinets, durable tool carts, versatile workbenches, space-saving wall organizers, and heavy-duty shelving units. Whether you’re a pro or hobbyist, we have a storage solution to fit your needs and budget.

sheet metal stamping guidelines|sheet metal design guidelines pdf