difference between additive manufacturing and cnc machining pdf Difference between Rapid Prototyping and Additive Manufacturing? Cost. Figure: Features that represent problems using CNC machining. STL uses triangles to describe the surfaces to be . $26.00

0 · cnc manufacturing additive manufacturing

1 · cnc machining vs am

2 · cnc machining vs additive manufacturing

3 · additive manufacturing technology

4 · additive manufacturing process

5 · additive manufacturing methods

6 · additive manufacturing definition

7 · additive manufacturing PDF

Our steel shelf brackets collection contains simple fixed designs for easy installation, models with integrated hooks for extending your closet possibilities, and floating shelf brackets that create a clean and spacious look in any room.

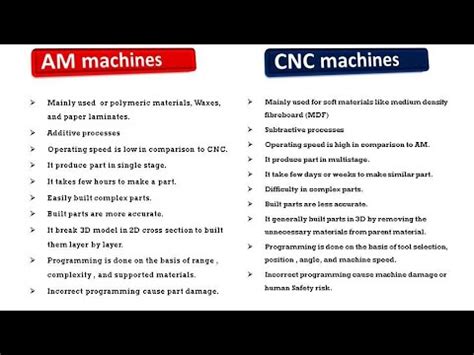

•The key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, while the CNC machining is subtractive. •This means CNC machining .Differentiate between Additive Manufacturing and Subtractive Manufacturing (CNC Machining). Critical/Creative Thinking: Analyze, evaluate, and synthesize information in order to consider .

Difference between Rapid Prototyping and Additive Manufacturing? Cost. Figure: Features that represent problems using CNC machining. STL uses triangles to describe the surfaces to be .

metal enclosure manufacturers in coimbatore

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production.an additive process, while CNC machining is a subtractive process. CNC machines start with a block of solid material and use sharp rotating tools to remove material until the product shape .Additive manufacturing (AM) is gaining popularity in industrial applications including new product development, functional parts, and tooling. However, due to the differences in AM .

Though additive manufacturing and CNC machining enjoy wide application in rapid prototyping, they differ significantly in material usage, design flexibility, lead time, production volume, cost, .

cnc manufacturing additive manufacturing

While AM and CNC machining both use computer-controlled tools, AM builds objects up from materials additively whereas CNC machining shapes objects by removing material from a starting block in a subtractive process.•The key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, while the CNC machining is subtractive. •This means CNC machining starts with a block of material (called a blank), and cuts away material to create the finished part. To do this, cutters and spinning tools are used to shape .

Differentiate between Additive Manufacturing and Subtractive Manufacturing (CNC Machining). Critical/Creative Thinking: Analyze, evaluate, and synthesize information in order to consider problems/ideas and transform them in innovative or imaginative ways.Difference between Rapid Prototyping and Additive Manufacturing? Cost. Figure: Features that represent problems using CNC machining. STL uses triangles to describe the surfaces to be built. Each triangle is described as three points and a facet normal vector indicating the outward side of the triangle, in a manner similar to the following: Cost.

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

Additive manufacturing (AM) is a relatively new manufacturing method that compiles different techniques to join materials together material on top of existing structure in order to make parts from 3D-model data—typically layer by layer. Additive manufacturing is a combination of.With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production.

an additive process, while CNC machining is a subtractive process. CNC machines start with a block of solid material and use sharp rotating tools to remove material until the product shape designed is produced. As an additive manufacturing process, there are several types of 3D printers that use different technologies and materials. Some

Additive manufacturing (AM) is gaining popularity in industrial applications including new product development, functional parts, and tooling. However, due to the differences in AM technologies, processes, and process implementations, functional and geometrical characteristics of manufactured parts can vary dramatically.Though additive manufacturing and CNC machining enjoy wide application in rapid prototyping, they differ significantly in material usage, design flexibility, lead time, production volume, cost, and surface treatment.While AM and CNC machining both use computer-controlled tools, AM builds objects up from materials additively whereas CNC machining shapes objects by removing material from a starting block in a subtractive process.

•The key difference between 3D printing and CNC machining is that 3D printing is a form of additive manufacturing, while the CNC machining is subtractive. •This means CNC machining starts with a block of material (called a blank), and cuts away material to create the finished part. To do this, cutters and spinning tools are used to shape .Differentiate between Additive Manufacturing and Subtractive Manufacturing (CNC Machining). Critical/Creative Thinking: Analyze, evaluate, and synthesize information in order to consider problems/ideas and transform them in innovative or imaginative ways.

metal extender on plastic box

Difference between Rapid Prototyping and Additive Manufacturing? Cost. Figure: Features that represent problems using CNC machining. STL uses triangles to describe the surfaces to be built. Each triangle is described as three points and a facet normal vector indicating the outward side of the triangle, in a manner similar to the following: Cost. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive manufacturing (AM) is a relatively new manufacturing method that compiles different techniques to join materials together material on top of existing structure in order to make parts from 3D-model data—typically layer by layer. Additive manufacturing is a combination of.With Additive Manufacturing (AM) material shaping process can be long. AM allows for freedom of design and personalized production, while CNC Machining excels in precision and mass production.

an additive process, while CNC machining is a subtractive process. CNC machines start with a block of solid material and use sharp rotating tools to remove material until the product shape designed is produced. As an additive manufacturing process, there are several types of 3D printers that use different technologies and materials. SomeAdditive manufacturing (AM) is gaining popularity in industrial applications including new product development, functional parts, and tooling. However, due to the differences in AM technologies, processes, and process implementations, functional and geometrical characteristics of manufactured parts can vary dramatically.

cnc machining vs am

cnc machining vs additive manufacturing

Though additive manufacturing and CNC machining enjoy wide application in rapid prototyping, they differ significantly in material usage, design flexibility, lead time, production volume, cost, and surface treatment.

metal exterior siding for houses

additive manufacturing technology

Our selection of telephone junction boxes come in all sizes from 10" to 48" high, for Type 1 and 3R Nema ratings for both outdoor and indoor projects.

difference between additive manufacturing and cnc machining pdf|additive manufacturing technology