difference between am and cnc machining Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their . $334.74

0 · difference between cnc and am

1 · cnc machining vs am

2 · cnc machining vs additive manufacturing

3 · 3d printing vs machining

4 · 3d printing vs cnc machining

Missing Your Key? For all pencil/supply box replacement keys, please click here.

difference between cnc and am

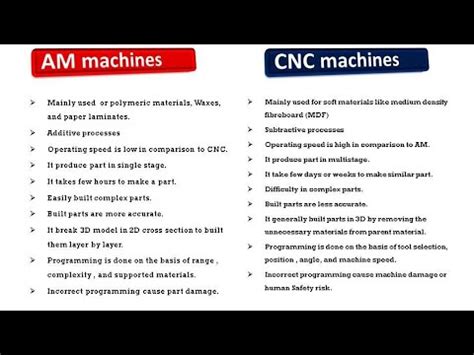

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final .

cnc machining vs am

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and .

Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their .

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time .

Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.

In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and .While AM is highly favorable for complex and custom designs, rapid prototyping and lower volumes, CNC machining excels in high-volume productions, providing strength and a wider .

Additive Manufacturing (AM) and CNC machining are two manufacturing methods that are used to create 3D parts. Both of these technologies use computer-aided design (CAD) files as the starting point for .

cnc machining vs additive manufacturing

Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility.

Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms. Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow. Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.

In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and applications, we aim to provide a comprehensive understanding of these powerful technologies.

While AM is highly favorable for complex and custom designs, rapid prototyping and lower volumes, CNC machining excels in high-volume productions, providing strength and a wider range of material options.

Additive Manufacturing (AM) and CNC machining are two manufacturing methods that are used to create 3D parts. Both of these technologies use computer-aided design (CAD) files as the starting point for creating a part, but they differ in how they create those parts.Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow. Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.In this post, we will explore and compare two prominent manufacturing methods: Additive Manufacturing (AM) and CNC Machining. By assessing their key differences, advantages, and applications, we aim to provide a comprehensive understanding of these powerful technologies.While AM is highly favorable for complex and custom designs, rapid prototyping and lower volumes, CNC machining excels in high-volume productions, providing strength and a wider range of material options.

cellwood white electrical box and mounting block

Additive Manufacturing (AM) and CNC machining are two manufacturing methods that are used to create 3D parts. Both of these technologies use computer-aided design (CAD) files as the starting point for creating a part, but they differ in how they create those parts.

3d printing vs machining

3d printing vs cnc machining

$12.88

difference between am and cnc machining|3d printing vs cnc machining