how to design a custom sheet metal part Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with . Magnetic materials are attracted to a magnet and may even become magnetized. Nearly all magnetic materials are metals. Familiar examples of magnetic metals include iron , nickel , cobalt , and steel.

0 · sheet metal pattern layout methods

1 · sheet metal part design guidelines

2 · sheet metal layout drawings

3 · sheet metal design rules pdf

4 · sheet metal design practice pdf

5 · sheet metal design calculations pdf

6 · how to fabricate sheet metal

7 · basics in sheet metal design

This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded.

Do you know of anyone who wants longer lead times? Probably not. Always remember to let your manufacturer know what kind of hardware you want to use by including the details in your top level assembly information. Whether it’s a self-clinching nut like CLS-440-2, flush-head stud like FHS-M5-15, or . See moreGenerally, finishes serve two purposes. They can protect your part or they can make it look better. Some do both. Aesthetic . See more

Imagine making hundreds of parts out of unfinished steel that are destined for installation in a salty, marine environment. Amazingly, we’ve seen quotes that request just that. Save . See more How to Design Sheet Metal Parts in 5 Easy Steps Step 1: Determine the Purpose of the Sheet Metal Part. Before starting to design a sheet metal part, it is important to clearly determine its purpose. This includes .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with .

The following are some design rules for slots and holes. Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet metal ( at least equal to sheet thickness). 2. Proper . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Whether you’re a seasoned . In most cases, we use a press brake with a v-shaped die to bend sheet metal parts. During the bending process, it’s important to have enough material to reach all the way across the die, otherwise, there’s nothing to catch .

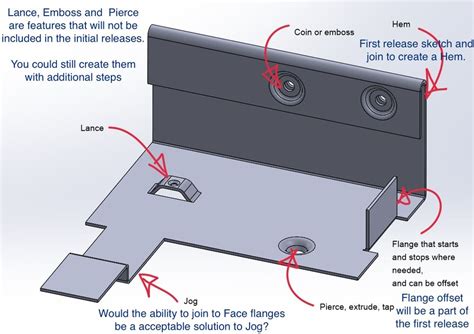

DESIGN TIPS • Tooling cost depends on the size of coin features. Smaller features require more expensive tooling and forming processes. • Significant material displacement may cause . While there are a few different ways you can begin designing a custom sheet metal part, Steve recommends starting in the center of your design area. Sometimes, designers will draw a feature skewed or off to the side .How to Design a Custom Sheet Metal Part. You need a sheet metal bracket but can’t find it at the local hardware or superstore. Look around the room you are in. Chances are you will see a number of applications where metal parts are used .

In Onshape, you can initiate a sheet metal design using several methods: you can convert a solid part into sheet metal; design from a flat sketch, then fold; use flange tools to add edges and features; or directly import and adapt existing .

sheet metal pattern layout methods

Custom sheet metal fabrication is a complex and specialized process that involves cutting, shaping, and manipulating sheet metal to create precise and tailored solutions for various industries. From automotive and . Sheet metal parts can be welded or riveted to create structural elements. Press-fit inserts, such as PEM inserts, can add mating features like bosses, threads, and more without the need of custom machining. Sheet .Flat and formed sheet metal for custom parts. Material by Type. Plastics. Various grades of plastics across molding, machining, and 3D printing . cut, lased, and sometimes cajoled into its final shape. It’s a very hands-on process. If you . we will learn How to make custom forming tool and Appearance in Solidworks sheet metal.1)Solidworks tutorial for Beginners.https://www.youtube.com/playlist?l.

Sheet metal parts can be welded or riveted to create structural elements. Press-fit inserts, such as PEM inserts, can add mating features like bosses, threads, and more without the need of custom machining. Sheet Metal Materials Sheet metal is often made of aluminum, copper, or steel. Sheet metal also has a wide variety of finishes.This guide resource focuses on design considerations for a sheet metal part to be fabricated. 704-825-1599 Email Us. Login. Cart (0) Resources. Metal Material Guide. Metal Types. Specialty Metals. Tool Steel. Choosing the Right Metal. Metal Finishing. . How to Design a .

This video demonstrates how to create a Custom Sheet Metal Form in IRONCAD.

Use the Custom Operations PropertyManager to create custom operations to apply additional costs to parts. Applying Custom Operations in Sheet Metal Parts. You can apply custom operations in the sheet metal template or in the CostingManager.How do people get custom metal parts for their projects, they can’t be spending hundreds of dollars on fairly small parts—can only imagine the cost of large parts. . Well, I think its reasonable to assume that most people that design custom parts and assemblies in CAD for a hobby purpose own a (hobby) cnc and make them themselves or can .When planning a bent part in Fusion 360, the first thing to do is create a sheet metal rule for your material of choice if you have not done so already. What are sheet metal rules? In 3D programs, sheet metal rules will include the information needed for the program to automatically calculate the correct formed versus flat dimensions for a part. Click OK to close the Custom Properties and return to your blank part file. Next, click File > Save As and change the file type to Part Template (.prtdot). If you wish, you can save this as a new Part Template file for Sheet Metal Parts or override your existing Part File Template depending on your organization's Document Standards. Figure 8.

Metal like aluminum, steel, stainless steel, copper, brass, and titanium are popular in manufacturing for various metal parts. Sheet fabrication techniques, CNC machining, drilling, EDM, metal 3D printing, and other similar technologies are used to produce custom metal parts, prototypes, and end-use products.Here, custom parts refer to designs of parts to solve some . 2 Sheet Metal Part Design for Manufacturing Tip. 2.1 OFFSETS; 3 How to Create Sheet Metal Offsets without Custom Tooling. 3.1 Step 1: We make sure we have the right tool. 3.2 Step 2: We set the press brake to how hard we want it to come down on the piece of metal. 3.3 Step 3: We manually stop the press brake to create the desired angle. We have many clients who are unable to complete the design themselves, either due to a lack of time due to other pressing projects, or a lack of knowledge in sheet-metal design and fabrication. Protocase is happy to provide Design Services, wherein a member of our Engineering & Design Services will create a custom design based off of your . Design Sheet Metal Parts with the Manufacturing Process in Mind. . At Approved Sheet Metal, we bring decades of expertise to custom sheet metal fabrication. A crucial aspect of our craft [.] Simplify, Consolidate, Save: 8 Key .

Family-owned and operated, APX York Sheet Metal brings more than 71 years of industry experience to each job. When you want quality components and reliable service, choose APX York Sheet Metal as your fabrication partner. Reach out to us online to learn more about how we can help bring your drawings to life. 2 Approved Sheet Metal’s Proven Approach to Corner Construction; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Metal Fabrication Corner Construction FAQ. 4.0.1 Why is .

Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Custom sheet metal parts in as little as 2 days. No minimum quantities; Free shipping; . If there’s ever an issue with a design file or part, you can count on their support team – especially Shawn . Gauge Used in sheet metal for the specify thickness of sheet metal part so in this tutorial we are going to learn about the How to create custom gauge table .At the top of the CostingManager, click Add Custom Operation.; In the PropertyManager, under Operation, select Add New.; Under New Operation, set options, then click .; The custom operation appears in the Custom Operations folder and the Estimated Cost Per Part updates. At Approved Sheet Metal, we bring decades of expertise to custom sheet metal fabrication.A crucial aspect of our craft is sheet metal forming, which shapes metal sheets into desired forms without removing any material.Most fabricated sheet metal parts require some degree of forming.

2. Pair a large part with a small part. One of the best ways to optimize sheet metal material is to pair a large part with a small part when getting a quote for custom metal fabrications. Once you know the standard sheet sizes available, you can determine how much material will be left over and get another part out of the remaining material that you’re already paying for.It improves the overall appearance of parts in design elements like safety warnings, company logos, and other graphics. . How to choose a custom sheet metal parts machining company. The best fabrication shop should combine components and precision sheet parts for rapid prototyping. In addition, a reputable shop should offer a cost-effective .

How to Add Custom Parts to SOLIDWORKS Toolbox . To create your own custom annotations mapped to specific Sheet Metal Properties, create an annotation within the Flat Pattern view’s border, and then add the property names accordingly. For example, to map the outer cut length, .Our online sheet metal fabrication service can ship custom sheet metal parts and assemblies in as fast as 1 day. Request a quote today to get started. . We now offer automated design analysis for all sheet metal components, which highlights any features that may pose challenges during the fabrication process. DFM feedback that can improve the .Cost considerations and optimization Factors affecting the cost of custom metal parts. Material Selection: Prices of different metals are affected by their availability and processing requirements.; Design complexity: Complex designs require more advanced machining and are costlier.; Production volume: Larger quantities lead to lower unit costs because of economies of scale. Learn about metal parts manufacturing & the best manufacturing process to create custom metal parts. Visit Evans Manufacturing for details. 360-652-4200 REQUEST A QUOTE. 360-652 -4200 . metal. Because of their malleability and lightweight, soft metals like aluminum and copper are frequently utilized to create sheet metal components. .

sheet metal part design guidelines

There are several colours that go well with a light grey house. For a classic look, you could pair it with a dark grey metal roof. For a more contemporary look, you could try a darker colour like charcoal or black. If you want to make a statement, a red or .

how to design a custom sheet metal part|sheet metal design calculations pdf