cnc lathe part programming pdf Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. Find Wyvern Sheet Metal & Fabrications Ltd in Worcester, WR3. Get contact details, videos, photos, opening times and map directions. Search for local Sheet Metal Work near you on Yell.

0 · haas lathe programming workbook PDF

1 · cnc turning program examples PDF

2 · cnc turning machine programming PDF

3 · cnc turning cycle program PDF

4 · cnc programming manual PDF

5 · cnc programming examples PDF

6 · cnc lathe programming example PDF

7 · cnc lathe manual PDF

When it comes to choosing between aluminum and stainless steel for heat transfer applications, one of the most critical factors to consider is thermal conductivity. While both materials possess unique characteristics and advantages, they differ considerably in their ability to .

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

The operation of the SL-Series Turning Center requires that a part program be designed, written, and entered into the memory of the control. There are several options for getting these .

yugioh metal raiders booster box 1st edition cheap

The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the .Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X .This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi.In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become .

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. More training and information are necessary before attempting to program the machine.

haas lathe programming workbook PDF

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

The operation of the SL-Series Turning Center requires that a part program be designed, written, and entered into the memory of the control. There are several options for getting these programs to the control. RS-232 (serial port with a computer), 3.5” Floppy Disk, Ethernet / Networking/ and USB are all viable ways to transmit and receive .The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK control enables the user to program complex workpiece programs (e.g. for free-form surfaces, channel coordination, .), and makes the programming of complicated

Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle centerline; positive X moves the tool away from the spindle

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi.In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

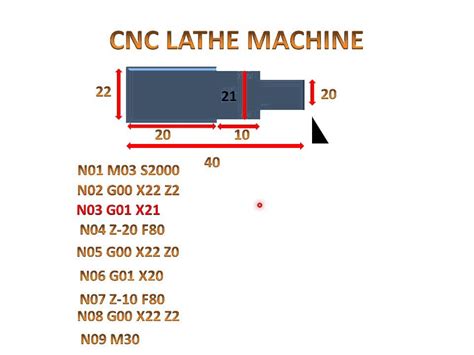

For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to

we will be able to program a large number of operations on the CNC lathe, with screens and explanatory diagrams to guide us. As well as the Manual Guide i, we have fixed sentences which we will use to complete everything we need to create a program from scratch, without having to know the different ISO programming sentences.This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. More training and information are necessary before attempting to program the machine.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.The operation of the SL-Series Turning Center requires that a part program be designed, written, and entered into the memory of the control. There are several options for getting these programs to the control. RS-232 (serial port with a computer), 3.5” Floppy Disk, Ethernet / Networking/ and USB are all viable ways to transmit and receive .

yellow box t junction

The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK control enables the user to program complex workpiece programs (e.g. for free-form surfaces, channel coordination, .), and makes the programming of complicatedLathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle centerline; positive X moves the tool away from the spindleThis file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi.In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to

cnc turning program examples PDF

cnc turning machine programming PDF

yellow box junction turning left

cnc turning cycle program PDF

AluBox specializes in 100% weatherproof aluminum storage boxes, cases, and containers, and offers a wide-range of standard box sizes for defense, industrial, emergency services, transportation, and recreational use.

cnc lathe part programming pdf|cnc lathe programming example PDF