sheet metal working process Sheet Metal Work Processes. Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. There are a large variety of . It is true that a metal roof will absorb heat when directly exposed to the sun. But so does any roof covering material. Darker roofs in materials like asphalt, ceramic, slate or any other material absorb heat at roughly the same rate.

0 · sheet metal stamping process pdf

1 · sheet metal processes pdf

2 · sheet metal operations with diagrams

3 · sheet metal operations pdf

4 · sheet metal manufacturing process pdf

5 · sheet metal forming process pdf

6 · perforating operation in sheet metal

7 · name various sheet metal operations

A proper, most effective Faraday cage has two layers of conductive enclosure, one nested within the other and bonded electrically at only one corner. So if adding aluminum panels to your already metal box, consider insulating them instead of riveting to exterior box. A box within a box. Grounded both together one corner. EDIT OOPS: Removed link.

Sheet Metal Work Processes. Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. There are a large variety of .Updated 16 August 2023. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods.The completion of a product usually comprises of many steps – from cutting and .

Sheet Metal Forming Basics. With the use of the industrial manufacturing process, sheet metal is formed by working metal into flat and thin pieces.Sheet metal is one of the very convenient ways that is used in metal working and it .Forming sheet metal. During the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized product. Entire product chassis can be . Sheet metal is a comprehensive cold working process for metal sheets (usually below 6mm). And the sheet metal process including shearing, punching, cutting, compounding, folding, riveting, splicing, forming, surface treatment, etc. The products processed by the sheet metal process are called sheet metal parts or sheet metal components Perbedaan Hot Working dan Cold Working dalam Proses Pembentukan Sheet Metal. 1. Hot Working. Di dalam pengerjaan panas, material (logam) terlebih dahulu dipanaskan sampai diatas tempratur rekristalisasi, sehingga sifat-sifat material akan berubah, di sini sifat material secara umum akan lebih ulet, lebih mudah dibentuk (tekanan lebih ringan .

usually performed as cold working Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick Plate stock > 6 mm thick Advantage - High strength, good . a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the . SHEETMETAL WORKING HISTORY Sheet metal working / stamping / formingwas developed as a mass production technology for the production of bicycles around the 1890’s. . (BPT 4413) • Deep drawing • A process in which sheet metal is stretched into the desired part shape. • A tool pushes downward on the sheet metal, forcing it into a die .Cutting is a sheet metal forming process where the main objective is to sever the metal by removing material. It is a crucial procedure in sheet metal manufacturing as it allows for the shaping and sizing of the metal to specific dimensions. . These processes reflect the complex nature of working with sheet metal and the expertise required to .

To complete the shaping process, the sheet metal piece’s free or unfixed edge is bent. V-bending. When a piece of sheet metal is squeezed between the die and the punch in this type of bending operation, it is shaped into a V-shape in the die. . Different types of sheet metal work tools. Conclusion. In conclusion, there are a variety of . Download Citation | Sheet Metal Shearing Process: An Overview | Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most .The document discusses various sheet metal working processes including cutting operations like shearing, blanking, and punching and describes how they work. It also covers bending operations and explains that bending plastically deforms sheet metal to permanently take the shape of the bend by compressing metal on the inside and stretching it on the outside. The cutting and .

sheet metal stamping process pdf

And drawing is cup or deep drawing when the cup depth is more than half its diameter [3]. A typical deep drawing process to produce a cup is shown in Fig 1. Fig 1: Deep Drawing Process [19] 2.1. Process parameters Every sheet metal process is governed by various parameters. In case of drawing the following parameters play a significant role.Incremental sheet forming or ISF forming process is basically sheet metal working or sheet metal forming process. In this case, sheet is formed into final shape by a series of processes in which small incremental deformation can be done in each series. Ironing Ironing is a sheet metal working or sheet metal forming process. .

The sheet metal blanking process is a fundamental aspect of the manufacturing industry that converts flat metal sheets into specific, predefined shapes for a variety of uses. This method is known for its efficiency and is especially advantageous for high-volume production. . Once set, they can work continuously without a regular check, which .

The metal-forming process involves cutting and stretching a sheet of metal through perforating scissors, creating a structurally advantageous diamond-shaped mesh. This process is commonly used for manufacturing fences, catwalks, platforms, and grating, resulting in self-draining, strong products that support weight.

Surface condition of sheet : Depends on rolling practice; important in sheet forming as it can cause tearing and poor surface quality Classification of sheet metal working processes Sheet metal Shearing Bending Drawing The term .

This can be either a hot or cold working process. Typical Metal forging types. Metal forging is a manufacturing process in which metal is shaped by compressive forces applied through various tools, such as hammers or .SHEET METALWORKING - Michigan State University The sheet metal manufacturing process begins with a large coil of metal fed into the sheet metal working machinery. The metal can be cut, stamped, or bent into the desired shape. Once the sheet metal has been formed into the desired shape, it .

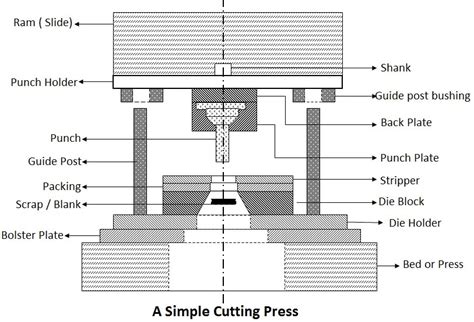

Punching is a prominent process in sheet metal fabrication that involves the use of a punch and die to create holes, slots, or other geometric features in sheet metal. This versatile technique is widely employed in the production of sheet metal components across diverse industries, including automotive, electronics, and construction. Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Clearance, punch and die sizes, angular clearance, and stripper usage are crucial factors in achieving precise cuts. Fine blanking requires special . 4.3 PROCEDURE DURING HANDLING THE MACHINERY Figure 1 : Flowchart of sheet metal working process in the workshop 1. A metal ruler, L square ruler, and scriber were used to measure the length of the sheet metal, which were 234 mm long and 40 mm wide with all four 90° edges. It is then cut using a bench machine. 2.

Sheet metal usually comes in rolls or flat sheet stock, which is inconvenient to work with. To effectively work with your sheet metal, you must shear it to the desired size. So, what is metal shearing? It’s a process that involves cutting and shaping large pieces of sheet metal to meet specific dimensions required for your project. The sheet metal working process begins with precise cutting using tools like shears, punches, and lasers, followed by bending and forming to give shape. Each step is important in creating detailed designs and functional parts. By understanding the complexity of metals, manufacturers can increase industrial efficiency, spur innovation, and .Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs.

21.1 INTRODUCTION OF MECHANICAL WORKING PROCESS. Mechanical working is a process of shaping of metals by plastic deformation. When a metal is subjected to external force beyond yield strength but less than fracture strength of the metal, metal is deformed by slip or twin formation. There are two types of mechanical working process: cold working . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

sheet metal processes pdf

sheet metal fabrication company in gujarat

sheet metal fabrication companies in singapore

sheet metal fabrication cylinder with collar

sheet metal operations with diagrams

Frequently-asked questions and answers about septic system distribution boxes or D-boxes: what is a D-box, where is the D-Box, why do we need a D-box, and how do I fix or replace a D-box? In this article series about septic system drop boxes we describe the best procedures for locating and inspecting, repairing or replacing the septic .

sheet metal working process|sheet metal manufacturing process pdf