best precision peek machining parts ProleanTech stands at the forefront of PEEK CNC Machining and is recognized as a leading Online PEEK CNC Machining service provider. Our expertise extends to delivering Expert PEEK Machining Solutions, ensuring precision and quality in every component we craft. Featuring a stainless steel construction with a mirror polished finish, this attractive bread box offers durability and a distinctly modern look to your guest service. Use it at self-service areas like breakfast bars and buffets to keep fresh-baked breads, bagels, danishes, and muffins fresher for longer and protected from contaminants.

0 · peek plastics

1 · machining peek specifications

2 · machining peek sizes

3 · machining peek plastics

4 · machining peek

5 · industrial grade peek plastic

6 · industrial grade peek

7 · aip machining peek

$5.00

This section delves into the precision engineering techniques vital for PEEK component machining, focusing on tool selection, speed adjustments, and temperature control, which are pivotal in preserving the integrity of PEEK . PEEK injection molding is best suited for mass production of complex parts PEEK, while PEEK CNC machining is suited for individual precise parts. Both methods aim to .

This section delves into the precision engineering techniques vital for PEEK component machining, focusing on tool selection, speed adjustments, and temperature control, which are pivotal in preserving the integrity of PEEK materials.

4 bedroom 3 bath metal house plans

PEEK injection molding is best suited for mass production of complex parts PEEK, while PEEK CNC machining is suited for individual precise parts. Both methods aim to capitalize on the beneficial properties of PEEK- its high melting temperature, for example- in the production of top-quality components.ProleanTech stands at the forefront of PEEK CNC Machining and is recognized as a leading Online PEEK CNC Machining service provider. Our expertise extends to delivering Expert PEEK Machining Solutions, ensuring precision and quality in every component we craft. Depending on your application, you’ll want to machine either industrial-grade PEEK or medical-grade PEEK. Industrial-grade PEEK is a strong, flame-retardant and abrasion resistant thermoplastic with high impact strength and a low coefficient of friction.Brogan & Patrick specializes in PEEK plastic machining and fabrication services. Our vast experience in PEEK plastic fabrication and machining enables us to assure precision and a high degree of customization when it comes to industrial PEEK machined parts.

Precision Machining: Utilize advanced CNC milling and turning techniques to meticulously craft PEEK parts to exact design specifications. Quality Assurance: Conduct thorough inspections at each stage to verify dimensional accuracy, surface finish, and overall quality before final approval.

peek plastics

CNC machining leads the way for PEEK processing. It offers unmatched precision and versatility. CNC machines handle complex parts with ease, making them ideal for PEEK's demanding applications. Turning is another effective method for shaping PEEK.E.J. Basler offers precision PEEK precision machined parts with superior quality, tolerances, and surface finish. The numerous advantages and benefits of PEEK precision machining services make it a preferred material for CNC, Swiss, and other machining techniques.

Advanced Industrial has extensive experience machining challenging parts from high-performance plastics, including machining PEEK. We offer a comprehensive suite of services designed to meet your specific project requirements and exceed your expectations.Emco Industrial Plastics offers custom PEEK machining and fabricating for industrial applications. PEEK is a difficult plastic to machine, requiring special handling to minimize internal stress and heat-related cracks during machining.

This section delves into the precision engineering techniques vital for PEEK component machining, focusing on tool selection, speed adjustments, and temperature control, which are pivotal in preserving the integrity of PEEK materials.

PEEK injection molding is best suited for mass production of complex parts PEEK, while PEEK CNC machining is suited for individual precise parts. Both methods aim to capitalize on the beneficial properties of PEEK- its high melting temperature, for example- in the production of top-quality components.ProleanTech stands at the forefront of PEEK CNC Machining and is recognized as a leading Online PEEK CNC Machining service provider. Our expertise extends to delivering Expert PEEK Machining Solutions, ensuring precision and quality in every component we craft.

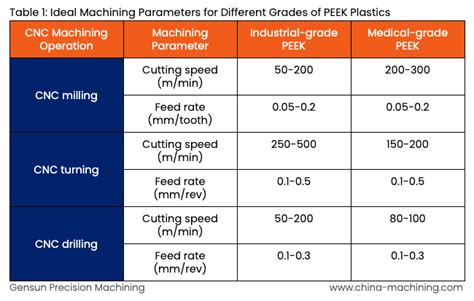

Depending on your application, you’ll want to machine either industrial-grade PEEK or medical-grade PEEK. Industrial-grade PEEK is a strong, flame-retardant and abrasion resistant thermoplastic with high impact strength and a low coefficient of friction.

Brogan & Patrick specializes in PEEK plastic machining and fabrication services. Our vast experience in PEEK plastic fabrication and machining enables us to assure precision and a high degree of customization when it comes to industrial PEEK machined parts.Precision Machining: Utilize advanced CNC milling and turning techniques to meticulously craft PEEK parts to exact design specifications. Quality Assurance: Conduct thorough inspections at each stage to verify dimensional accuracy, surface finish, and overall quality before final approval.CNC machining leads the way for PEEK processing. It offers unmatched precision and versatility. CNC machines handle complex parts with ease, making them ideal for PEEK's demanding applications. Turning is another effective method for shaping PEEK.

E.J. Basler offers precision PEEK precision machined parts with superior quality, tolerances, and surface finish. The numerous advantages and benefits of PEEK precision machining services make it a preferred material for CNC, Swiss, and other machining techniques.Advanced Industrial has extensive experience machining challenging parts from high-performance plastics, including machining PEEK. We offer a comprehensive suite of services designed to meet your specific project requirements and exceed your expectations.

4 electrical outlet boxes plaster rings

machining peek specifications

machining peek sizes

4 ft metal flower box

machining peek plastics

The meaning of WOOD is the hard fibrous substance consisting basically of xylem that makes up the greater part of the stems, branches, and roots of trees or shrubs beneath the bark and is found to a limited extent in herbaceous plants. How to use wood in a sentence.

best precision peek machining parts|machining peek specifications