most common sheet metal material Choosing the correct sheet metal for your manufactured product can be confusing. Here are some things to look for when considering four of the most common types of sheet metal in the industry. • Connect multiple fountain lights to a single power supply with these bronze junction boxes. • Available in two sizes - four or eight outlet. • Also available with solid bottom or a built-in 1" threaded inlet in bottom which can thread onto BWF10 bronze flange (below), once installed fill with junction box potting compound (sold separately)

0 · which thickness called sheet metal

1 · standard size of sheet metal

2 · sheet metal material specifications

3 · sheet metal material list

4 · secc vs sgcc

5 · maximum thickness of sheet metal

6 · different types of sheet metal

7 · characteristics of sheet metal

PackIt Freezable Classic Lunch Box, Unicorn Sky Pink, Built with EcoFreeze Technology, Collapsible, Reusable, Zip Closure With Zip Front Pocket and Buckle Handle, Perfect for School Lunches

Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Table of Contents hide. I What Is Sheet Metal? II Common Materials. III Standard Sizes. IV Hot-Rolled vs Cold-Rolled Sheet Metal. V Forming Processes for Sheet Metal. What . Sheet metal is required across many industries, from automotive to aerospace, construction to electronics. The wide range of materials it offers, such as aluminum, steel, and copper, lends to its versatility, each providing .Choosing the correct sheet metal for your manufactured product can be confusing. Here are some things to look for when considering four of the most common types of sheet metal in the industry.

Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators.Today’s most common sheet metal types in industry include stainless steel, aluminum, carbon steel, and copper. Understanding your project’s specific needs is the key to choosing the suitable sheet metal. Consider factors like strength, . Learn The Types. Sheet metal is a versatile material used in various industries for its durability, flexibility, and ease of fabrication. Here are some common types of sheet metal: . In this guide, we'll look at the most common sheet metal materials used and go over the factors that need to be considered when choosing the right material.

Sheet metal is available in various levels of thickness based on the industry and desired specifications. In addition to flat panels, sheet metal can be rolled into coils, cut, bent, or punched into various shapes, making it an extremely versatile material. Common Types of Sheet Metal. The most common types of materials used for sheet metal . Common Types of Sheet Metal - Aluminum Sheet Metal Aluminum sheet metal stands out for its non-magnetic nature, lightweight structure, and corrosion resistance. This material is particularly favored for its excellent . Most processing plants will inventory hundreds and hundreds of sheets in various metal gauges and sheet sizes. The most common sheet metal size is likely four-foot wide by ten-foot long. . We work with a combination of . Whether you're working on a small DIY project or a massive industrial job, understanding the properties of different sheet metals can help you make an informed decision. Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. ALUMINUM

which thickness called sheet metal

The 7 Most Common Sheet Metal Bending Mistakes . Few things are quite as frustrating as putting the sweat equity into designing a part, selecting the perfect material, getting the finish just right, and finally ordering the part, only to have it arrive with bends distort at the ends, caused cracking in the surface of the material, or warped the .

A list of the most common sheet metal materials used for fabrication have been summarized below. Section 2 Hot Rolled Steel (HRS) Hot rolled steel is produced when steel is processed by a series of roll presses at temperatures over 1700°F. The process creates a steel that is easily formed or shaped into large pieces and is best used where . Selecting the Best Material for Your Sheet Metal Fabrication 5/6/2020 How Material Properties Impact Air Bending Precision and Tolerances 5/6/2020 news; REQUEST A QUOTE; About. Blog Laser . Some of the most common solutions include: SolidWorks:One of the most extensively used design and assembly software packages. It has a complete set of .

In most of the world, sheet metal thickness is consistently specified in millimeters. . Sheet metal of iron and other materials with high magnetic permeability, also known as laminated steel cores, has applications in transformers and electric . The four most common aluminium grades available as sheet metal are 1100-H14, 3003-H14, 5052-H32 .Hot Rolled Steel. This is the most common and simple finish and the first step to making steel plates and sheets. A steel slab is heated, typically to 1,700 degrees F, and passed through a series of rollers - each set of rollers making the slab thinner until the desired thickness is achieved. 1.0.1 Approved Sheet Metal 6061-T6 vs 5052-H32; 2 5052, 6061, 7075 Grade Aluminum Sheet Metal for Fabrication; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Aluminum Grades FAQ. 4.0.1 What are sheet metal aluminum grades? 4.0.2 Which aluminum grade should I choose? 4.0.3 What are the characteristics of 5052 aluminum? The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great fit for most engineering purposes. That is why we see it everywhere around us. At the end of the article, we will be discussing different forming methods used with sheet metal. Common Materials

standard size of sheet metal

Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal part-forming processes, and their applications.

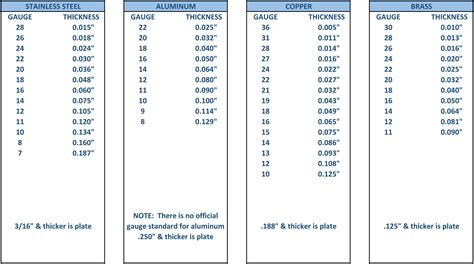

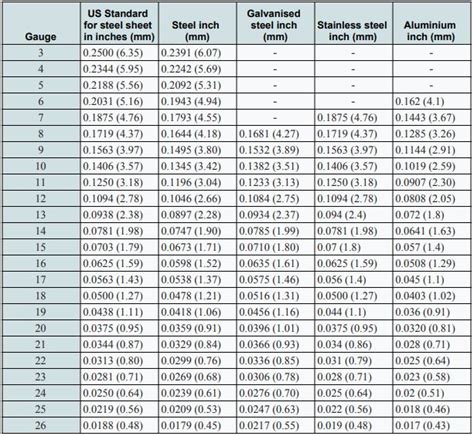

In the US, most sheet metal is sized by gauge. The bigger the gauge, the smaller the thickness. It is different for different metals. If you're making a pellet stove of your own, then you'll probably want something fairly thick, like 11 gauge (which is roughly 1/8" thick in stainless) or thicker.Definition of Sheet Metal: Understanding its properties and forms. Sheet metal refers to thin, flat metal formed by industrial processes. These versatile materials come in various thicknesses, typically from 0.006 to 0.25 inches. Sheet metal can be bent, cut, and shaped into many forms. This versatility makes it useful for countless applications.

4 square junction box cover

Common Sheet Metal Materials. Sheet metal is available in a wide range of materials, each with its own unique properties and characteristics. The most commonly used sheet metal materials include steel, aluminum, copper, and titanium, along with their respective alloys. The choice of material depends on factors such as strength, corrosion . Aluminium sheet metal is among the most widely used sheet metal materials today, mainly because of its versatility. Aluminium is light, resistant to corrosion, and pliable enough to be worked into a wide range of .

Steel is one of the most common metal materials found in everything from construction to electronics. However, there are multiple types of steel that fit various applications. . Understanding the differences between the most common types of sheet metals equips plant managers with the knowledge to best supply their technicians. With your . Let’s talk about some of the most common fastener options that are readily available for sheet metal projects: PEM Nuts: PEM nuts are used for strong, permanent threads in thin metal without adding a bulk in your sheet—ideal where traditional threading might not be an option due to the thin material thickness. Aside from carbon and iron, carbon steels contain only trace amounts of other components. Carbon steels are the most common of the four steel grades, accounting for 90% of total steel production! Carbon steel is classified into three subgroups based on the amount of carbon in the metal: Low carbon steels/mild steels (up to 0.3% carbon)

Understanding Sheet Metal Materials Types of Sheet Metal. Aluminum: Aluminum sheet metal is known for its lightweight yet strong properties, . and fabricators tailor several methods to different needs and materials. Shearing is one of the most common methods, ideal for straight cuts, and widely used for simplicity and efficiency. . Steel is one of the most common materials used in precision sheet metal fabrication because of its strength, durability, and corrosion resistance. . When to Use Cold-Rolled Steel for Sheet Metal Fabrication. Unlike hot-rolled steel, cold-rolled steel is aesthetically pleasing, with a smooth and shiny surface that feels oily to the touch. . The most common sheet metal material is mild steel (low carbon steel), widely used in various industries due to its cost-effectiveness, strength, and ease of fabrication. Mild steel is particularly favored for automotive body panels, construction, and appliances.

sheet metal material specifications

Most Common Ball Materials. Ball Technical Data Sheet #1 Metals Used to Manufacture Balls. Metal . Manufactured from Magnetism Machinability . Chrome Alloy Steel Balls, the most common bearing alloy, are manufactured from steel of the hardening type AISI E-52100. The balls are heat treated to a hardness of 62 HRC minimum. The most commonly used type of metal sheet is stainless steel sheets, containing 13% or less Chromium. As a result, stainless steel has a default quality of being ultra-durable. . Other Minor Metal Sheeting Material List. . Some of the most common ones are-Galvanized steel sheet. Galvalume coated sheet. Aluminum sheet. Zinc, copper, and .

Popular sheet metal materials include: Stainless Steel. Stand and spring-like stainless steel are the two categories used in sheet metal fabrication. Standard stainless can be non-magnetic; any of the 300 series steels are the most commonly used type of stainless. It does not require hot work or other stress relief during manufacturing.The Most Common Metal Roofing Materials. The most common metal roofs today are made of painted steel, aluminum, and galvanized steel. All these materials are affordable, durable, and low-maintenance, making them popular choices for residential metal roofing and commercial or agricultural needs alike. . It is a steel sheet dipped in a coating .Common materials used for sheet metal fabrication. This section compares the properties of different grades of the standard sheet metal fabrication materials offered by Protolabs Network, including aluminum, stainless steel, mild steel, and copper. . The most common type of fasteners for sheet metal are called PEM fasteners. PEM is a brand .

sheet metal material list

secc vs sgcc

maximum thickness of sheet metal

United Machine Metal Fab. is a leading provider of CNC machining and finishing services in Conover, NC. With a team boasting a century of combined experience, they specialize in 5-axis machining, grinding, EDM, fabrication, and inspection to deliver high-quality parts and exceptional customer service.

most common sheet metal material|which thickness called sheet metal