single hem sheet metal Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the . Give your dog the freedom they deserve and get them a large outdoor dog house for comfortable stay. We have a huge selection of quality large dog houses for sale to choose from made of .

0 · what is sheet metal hemming

1 · types of sheet metal hemming

2 · sheet metal hems types

3 · sheet metal hemming tools

4 · sheet metal hemming sizes

5 · sheet metal hemming machine

6 · sheet metal hem forms

7 · open hem sheet metal

Okay, so you have what used to be a lighted mirror, essentially. They wouldn't have had a junction box, and now you need to put a light fixture up.

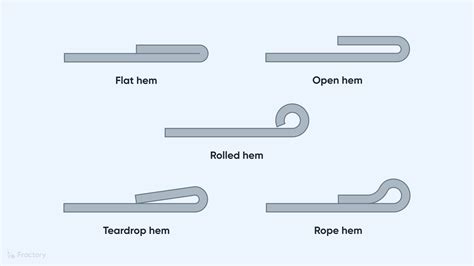

The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem.In this sheet metal hem design guide, you will find all the information. Whether you want to learn about the techniques, or classification criteria, this guide has all information you are looking for.

Sheet metal hemming is a metal-forming technology that involves rolling or folding sheet metal edges over and onto itself. You have to fold over the edges of sheet metal to create an area with two layers.Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the . Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in .Hem bends add another layer of rigidity to any edge of a part, rather than a bare single-layer edge. This can be especially useful in long sections of a sheet-metal part that could be unstable. Hem bends will help keep the edges of a part straight and will drastically cut down on how much the material flexes.

what is sheet metal hemming

This video discusses the different commonly used connection joints found on Sheet Metal Duct work.

3 4 electrical box extender lowes

Study with Quizlet and memorise flashcards containing terms like true or false, a double hymn requires two folding operations?, true or false, the width of the bend is limited in a bar folder?, allowance for metal thickness is not required when making seams of what gauge or lighter on a bar folder? and others.Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. Hemming Straight Hem.(Image source) (Image source) Contour hemming.(Image source) Hem detail.(Image source) Types of Hemming.(Image .

Different Types of Sheet Metal Hems. Each hem has its specific uses and advantages. Therefore, the selection of the appropriate hem should be based on the specific application requirements. . As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge .A hem is a folded over edge on a piece of metal. It is used to finish off rough, sharp ends of metal sheet and to strengthen and improve the appearance of a project. Allow about 1 4 " for the hem. When using metal heavier than 22 gage, increase the hem to. 5 16 " or. 3 8 ". A double hem is a single hem, repeated. A double hem provides much . This paper present a systematic review of sheet metal hemming process based on materials used in hemming process, analytical models, experimental and computational investigations made in the domain of sheet metal hemming process. . Development of Tool Paths for Multi-axis Single Stage Incremental Hole-flanging. Procedia Manufacturing, Volume .

A hem provides stiffness to a design, or provides a smooth, rounded external edge on a part to eliminate sharp edges. You can create single, double, rolled, and teardrop hems. On the ribbon, click Sheet Metal tab Create panel Hem . In the Type drop-down list, click one of the following: Single ; Teardrop ; Rolled ; Double Answer: Let’s begin by looking at the hem. While those in the sheet metal trade form dozens of different kinds of hems and seams, most are simply outdated, and only three are in general use. . You need to treat it as if it were a single piece of material. Your second option is to form the two 90-degree bends separately, each to a different . The next stop on our tour of the sheet metal functions in Solid Edge is the Hem tool. Hem is just meant to fold over the edges of parts usually for safety, aesthetic, or strength issues. .A basic (single axis) bend is the most foundational sheet metal forming operation. Despite the relative simplicity of the bending process, there is a lot to consider as a designer. . Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and .

Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with 700N/mm 2 tensile strength (stainless steel); There are four primary hemming bending solutions designed to accommodate various bending . Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Common sheet metal design guidelines in Hem Feature Guidelines or Hem. Alternative ways to create a hem in the Fusion sheet metal workspace: Cut and combine flanges Create two flanges of a 90-degree angle separated by a distance. . Go to the Solid toolbar and use the combine command to add the two parts into a single sheet metal component. This new component can be unfolded. Refer to the video: Sketch and .

A hem provides stiffness to a design, or provides a smooth, rounded external edge on a part to eliminate sharp edges. You can create single, double, rolled, and teardrop hems. On the ribbon, click Sheet Metal tab Create panel Hem . In the Type drop-down list, click one of the following: Single ; Teardrop ; Rolled ; Double One common technique is the single fold hem, where a single edge of the metal sheet is bent over to create a hem. This technique is often used for joining two metal sheets together or for reinforcing the edge of a sheet. .

It stiffens the sheet and does away with the sharp edge. Generally, two types of Hem joint – single hem and double hem – are there. Single Hem joints are made by folding the edges of the sheet over once to make it smooth and stiff while . Q2. What is the preferable length of a hem on sheet metal? For open hems, The preferred hem length should be between 0 and 2mm. 16 to 0. It ranges from 5 inches and may vary depending on the sheet metal thickness. Closed hems generally have suggested heights ranging between 0. 24 and 0. 75 inches. Q3. Is it expensive to hem sheet metal parts? Sheet Metal Hemming vs Seaming. In hemming, the sheet metal folds onto itself, with or without a cavity in between. It can have different cross-sections based on the type of hem. . Hemming involves folding the edge of sheet metal back onto itself, creating a single curve that strengthens and smooths the edge. On the other hand, a jog (or . In this Tech Tip we will explain about Creation of Hem in sheet metal in Autodesk Inventor. To create a hem in sheet metal using Autodesk software. In Autodesk Inventor, creating a hem in sheet metal involves defining material thickness, sketching the hem profile, and using specialized tools to fold and reinforce edges for enhanced structural .

This document discusses various edges, joints, seams, and notches used in sheet metal work. It describes single and double hem edges, wire edges, grooved seam joints, cap strip seams, drive slip joints, 'S' joints, lap seams, grooved seams, Pittsburgh lock seams, standing seams, dovetail seams, and square, slant, and V notches. > have a 10" DIA. i.d. X 3.00" long X .0299" thk. circular sheet metal part. i want to put a single hem on each of the edges (top and bottom) of the part - i can't do it? i also wanted to put opposing hems as to where the sheet metal comes together at both ends when it meets together when its rolled up - ie: like in a furnace duct where the two .

Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the bend.. The basic principle of the . 26 Sheet metal joints • Hems & seams – • A hem is an edge or border made by folding • It stiffens the sheet of metal and does away with the sharp edge • seam is a joint made by fastening two edges together • Types of hems – 1. single hem 2. double hem 3. wired edge • Single hem is made by folding the edges of sheet metal over to .The allowance for the double-hem edge is twice the width of the hem. Figure 2-55. - Double-hem edge . A WIRE EDGE (fig. 2-56) is often specified in the plans, Objects, such as ice-cube trays, funnels, garbage pails, and other articles, formed from sheet metal are fabricated with wire edges to strengthen and . Figure 2-54. - Single-hem edge.Versatile, compact 18-inch (46 cm) drip edge folding tool makes quick bends along the drip edge of flat-pan standing seam metal roofing panels.Two rib-reinforced steel plates are permanently welded together to create two folding seams for making 1-inch (25.4 mm) and 1-1/2-inch (38.1 mm) deep bends in maximum 22-gauge (0.76 mm) steel.

QH-50 Quick Hem for Single Side Drip Edge Hemming. . Ideal for roofing contractors, sheet metal fabricators, and HVAC shops. Form your hem/kick and finish it to the desired shape with your brake. UH-24 24 Inch Universal Hemmer with Flat Hem and Hem Kick.

Brenco is your premier metal cutting, forming, fabrication and processing solutions provider in Vancouver and surrounding area. Our services include laser and waterjet steel and metal cutting, metal shearing, plasma cutting, steel rolling, forming and custom metal fabricating.

single hem sheet metal|what is sheet metal hemming