cnc machine direction One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC . While junction boxes should be water-tight, they must also be designed to allow for easy access for maintenance and inspection. Some junction boxes come with hinged or .

0 · z axis in cnc machine

1 · z axis direction cnc

2 · easy cnc coordinate system

3 · cnc work coordinate system

4 · cnc machine coordinates

5 · cnc coordinates x y z

6 · cnc coordinate system diagram

7 · cnc 3 axis machine

You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means .

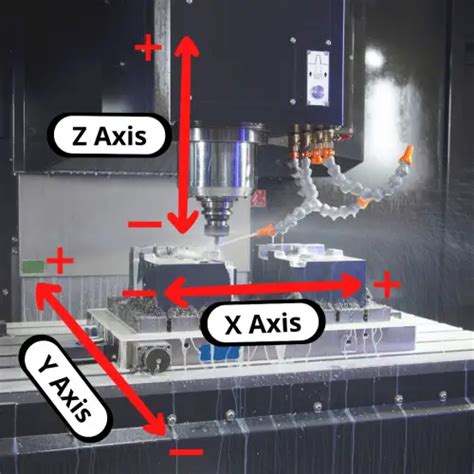

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. .One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC . The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.

One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC .

In this video, I’ll take a step back, return to the basics, and identify two of t.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by. Cartesian .

So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index .

CNC machines rely on the X, Y, and Z axes to precisely guide the cutting tool, where the Z axis determines the vertical position of the spindle and cutting tool. Determining the positive . Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line. One point on the line gets designated as the Origin. Any numbers to the left of the Origin .One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process.

The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications.In this video, I’ll take a step back, return to the basics, and identify two of t.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by. Cartesian coordinate system – cnc axis directions

z axis in cnc machine

z axis direction cnc

So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index finger the Y axis.

CNC machines rely on the X, Y, and Z axes to precisely guide the cutting tool, where the Z axis determines the vertical position of the spindle and cutting tool. Determining the positive direction of the Z-axis is important for programming, setup, and operation.

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.

Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line. One point on the line gets designated as the Origin. Any numbers to the left of the Origin .

One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process. The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.One essential aspect of CNC machines is the coordinate system, which is used to precisely position the cutting tool and workpiece. In this blog post, we will dive deep into the CNC machine coordinate system, exploring its components, principles, and applications.In this video, I’ll take a step back, return to the basics, and identify two of t.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by. Cartesian coordinate system – cnc axis directions

So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index finger the Y axis.

easy cnc coordinate system

cnc work coordinate system

Yes, ammo cans are generally considered to be EMP-proof due to their sturdy construction and metal composition. The metal acts as a Faraday cage, effectively shielding the contents from the electromagnetic pulse.The best advice is where NOT to store your ammo. Don’t store your ammo in: An unheated/cooled garage; An unheated/cooled attic; Your vehicle; OR the original boxes; 2. Purchase high-quality ammo cans. I .

cnc machine direction|cnc machine coordinates