cnc cad machines classical music Classical Guitar. Luthiers. EN - Forum guitare classique - Forum chitarra classica - Foro guitarra clasica - Free sheet music for classical guitar - Delcamp.org Publications - . Type AB Self-Tapping Screws, Type B Self-Tapping Screws, Type 25 Thread Cutting Screws. (All require the same pilot hole and drill bit sizes.) Have any questions? Talk with us directly using LiveChat.

0 · how to cnc a violin

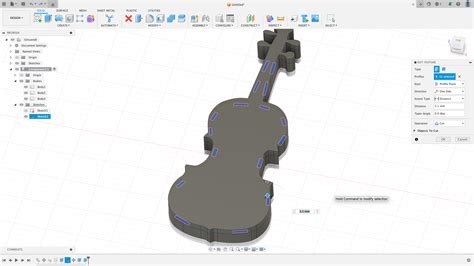

1 · dutch violin cnc machine

2 · cnc machined violin

3 · cnc file violin

Metal studs require special screws like self-tapping metal screws or toggle bolts for secure mounting. Always use a stud finder to locate metal studs accurately before drilling. Ensure the TV wall mount kit is compatible with metal studs for stability and safety.

CNC machines are all about accuracy & consistency. Taylor Guitars uses the CNC cuts for various guitar parts of their instruments. People who employ these machines are .

Hi guys, Does anyone have g-code for a classical guitar bridge? I'm very new to cnc and have not learned to draw one up in cad yet. I built a 3 axis ma.

See how Frank van der Horst used CAD and CNC to improve the classic violin design, using the DeskProto 3D CAM software.

Classical Guitar. Luthiers. EN - Forum guitare classique - Forum chitarra classica - Foro guitarra clasica - Free sheet music for classical guitar - Delcamp.org Publications - .

So, if you’re looking for a machine to help you build (and sell) your own custom guitars, this guide is for you. I’ve researched and selected a handful of excellent hobby-level CNC machines with the right sizing, features, and .

Hello, I´m a newbie regarding CNC, but I´m much more a technology guy than carpenter/manual worker, but I have some ideas for building flamenco guitars. Tradicitionally, .From the hobbyist to professional musical instrument manufacturers, CAD/CAM software opens the door for the creation, design and cnc manufacturing of musical instruments and component parts.Spending some quality time with calipers is probably the best way to get a model. Hello everyone, I wish to use a CNC to engrave or rather create a neck for a classical guitar. However my .Some of these plans also include 2D CNC plans you you can test them on your computer system for free, before you order more expensive 2D plans. Silicone Heating Blankes for Guitar and .

Personally, I found Etsy to be the best and most reliable site for trustworthy CNC guitar designs by far. Etsy isn’t just for baskets and blankets, plenty of CAD software wizards . CNC machines are all about accuracy & consistency. Taylor Guitars uses the CNC cuts for various guitar parts of their instruments. People who employ these machines are usually into batch or mass production guitars; at least that's when i think it makes sense to acquire a costly system like this. Hi guys, Does anyone have g-code for a classical guitar bridge? I'm very new to cnc and have not learned to draw one up in cad yet. I built a 3 axis ma.

See how Frank van der Horst used CAD and CNC to improve the classic violin design, using the DeskProto 3D CAM software.I started the thread, because, I have some doubts related 2.5D, 3D capablities of some machines/software, and because seem most topics are oriented to electric guitars, that are different horses, so in classical/flamenco guitars must join (glue the parts) even if . Discuss of CNC machining electric guitar body shaping, template making, inlay part cutting and pocketing, neck shaping and carving. What is the preferred oil/lacquer to use on a guitar neck finish? First CNC guitar project - Making a guitar from a video game (and flipping it lefty!) Any usable Les Paul 3d files? Need Help!- Strat Jack Plate. Classical Guitar. Luthiers. EN - Forum guitare classique - Forum chitarra classica - Foro guitarra clasica - Free sheet music for classical guitar - Delcamp.org Publications - International Competition for Classical Guitar 2025 - Sea kayaking - Qigong and Taijiquan - Lessons - Delcamp's volume D01 - D02 - D03 - D04 - D05 - D06 - D07 - D08 - D09 - D10 - D11 .

So, if you’re looking for a machine to help you build (and sell) your own custom guitars, this guide is for you. I’ve researched and selected a handful of excellent hobby-level CNC machines with the right sizing, features, and capabilities for guitar building:

ferramenta acionada para torno cnc

Hello, I´m a newbie regarding CNC, but I´m much more a technology guy than carpenter/manual worker, but I have some ideas for building flamenco guitars. Tradicitionally, all the parts here in Spain were built like carptenter from the headstock to the end, even they tend to follow the most rudimentary "ways" and tools that require lots of time.

From the hobbyist to professional musical instrument manufacturers, CAD/CAM software opens the door for the creation, design and cnc manufacturing of musical instruments and component parts. Spending some quality time with calipers is probably the best way to get a model. Hello everyone, I wish to use a CNC to engrave or rather create a neck for a classical guitar. However my knowledge on the matter of 3d modelling and.

how to cnc a violin

CNC machines are all about accuracy & consistency. Taylor Guitars uses the CNC cuts for various guitar parts of their instruments. People who employ these machines are usually into batch or mass production guitars; at least that's when i think it makes sense to acquire a costly system like this. Hi guys, Does anyone have g-code for a classical guitar bridge? I'm very new to cnc and have not learned to draw one up in cad yet. I built a 3 axis ma.See how Frank van der Horst used CAD and CNC to improve the classic violin design, using the DeskProto 3D CAM software.

I started the thread, because, I have some doubts related 2.5D, 3D capablities of some machines/software, and because seem most topics are oriented to electric guitars, that are different horses, so in classical/flamenco guitars must join (glue the parts) even if . Discuss of CNC machining electric guitar body shaping, template making, inlay part cutting and pocketing, neck shaping and carving. What is the preferred oil/lacquer to use on a guitar neck finish? First CNC guitar project - Making a guitar from a video game (and flipping it lefty!) Any usable Les Paul 3d files? Need Help!- Strat Jack Plate. Classical Guitar. Luthiers. EN - Forum guitare classique - Forum chitarra classica - Foro guitarra clasica - Free sheet music for classical guitar - Delcamp.org Publications - International Competition for Classical Guitar 2025 - Sea kayaking - Qigong and Taijiquan - Lessons - Delcamp's volume D01 - D02 - D03 - D04 - D05 - D06 - D07 - D08 - D09 - D10 - D11 . So, if you’re looking for a machine to help you build (and sell) your own custom guitars, this guide is for you. I’ve researched and selected a handful of excellent hobby-level CNC machines with the right sizing, features, and capabilities for guitar building:

Hello, I´m a newbie regarding CNC, but I´m much more a technology guy than carpenter/manual worker, but I have some ideas for building flamenco guitars. Tradicitionally, all the parts here in Spain were built like carptenter from the headstock to the end, even they tend to follow the most rudimentary "ways" and tools that require lots of time.From the hobbyist to professional musical instrument manufacturers, CAD/CAM software opens the door for the creation, design and cnc manufacturing of musical instruments and component parts.

dutch violin cnc machine

cnc machined violin

From there, you can determine which welder is best for you. The most common processes are MIG, TIG and stick. Each has benefits and limitations for certain applications. There’s no one-size-fits-all approach. MIG/Gas Metal Arc Welding (GMAW) — MIG welders use a wire welding electrode on a spool fed automatically at a constant pre-selected speed.

cnc cad machines classical music|cnc machined violin