cnc additive machining The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while . The sleek stainless steel doors blend seamlessly with the grill cabinet doors. Each cabinet contains two adjustable shelves to allow you to put your favorite items, from the roast holder to the pizza stone, right at the grill so they are always within reach.

0 · difference between cnc and am

1 · cnc machining vs am

2 · cnc machining vs additive manufacturing

Elevate your sheet metal fabrication with our precision Sheet Metal Notching Machines. Designed for accuracy and efficiency, our machines deliver crisp notches effortlessly. Ideal for HVAC, automotive, and construction industries, they offer versatility and reliability.

difference between cnc and am

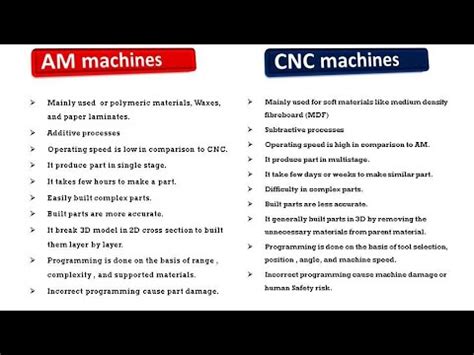

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .

Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining .

Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors .

CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can . Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive . CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production.

CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining removes material from the workpiece, resulting in excess waste.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.

CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can produce complex, three-dimensional parts with exceptional accuracy. Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.

cnc machining vs am

CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production. CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility. The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

While both additive manufacturing and CNC machining work with metal to produce components, there are significant differences. Explore the processes & find which is best for your production.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Additive manufacturing is more resource-friendly as it uses less material compared to CNC machining. In AM, material is only added where it's needed, reducing waste. CNC machining removes material from the workpiece, resulting in excess waste.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can produce complex, three-dimensional parts with exceptional accuracy.

Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop. CNC machining is an ideal choice for manufacturing high-precision and high-quality parts, while additive manufacturing is suitable for manufacturing complex geometric shapes and small batch production.

• Universal Smoker box is compatible with most gas grills, including any er Q 2000 and larger • Imparts natural smoky flavor into gas-grilled foods • Forged with stainless steel for easy upkeep and long-lasting use

cnc additive machining|cnc machining vs additive manufacturing